Refining method of tetra (dimethylamino) hafnium

A technology of dimethylamino and purification methods, which is applied in chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, and organic compounds of Group 4/14 without C-metal bonds, etc., and can resolve Hf elements and Zr It is difficult to separate elements, the products cannot meet the purity requirements of the electronics industry for the use of products, and it is difficult to prepare high-purity products, etc., to achieve the effects of less investment, low equipment requirements, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for refining tetrakis(dimethylamino) hafnium, the specific scheme is as follows:

[0030] Add 80g of tetrakis(dimethylamino)hafnium crude product into the refining reaction kettle, add 0.5g of adsorption resin under the protection of nitrogen, control the temperature at 30°C, stir and mix for 20min, filter and remove the adsorption resin, and then add tetrakis(dimethylamino)hafnium crude product Import it into a still, control the temperature at 10°C, remove the volatile components under reduced pressure, then raise the temperature to 80°C, and distill under reduced pressure to obtain the refined tetrakis(dimethylamino)hafnium product.

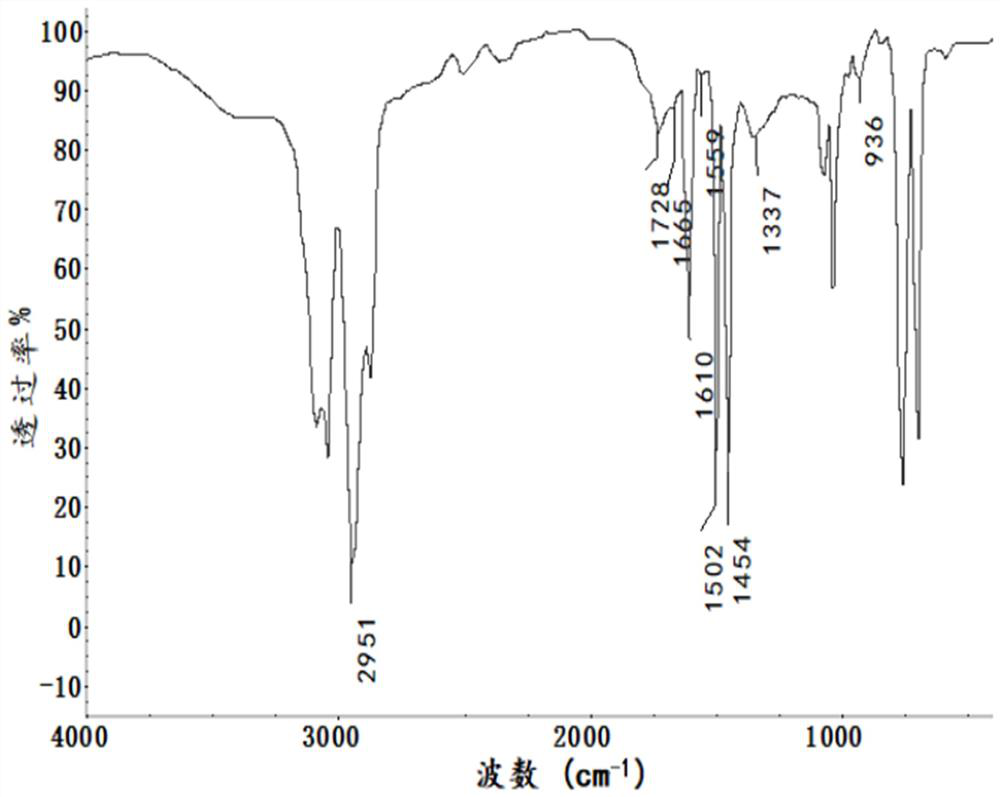

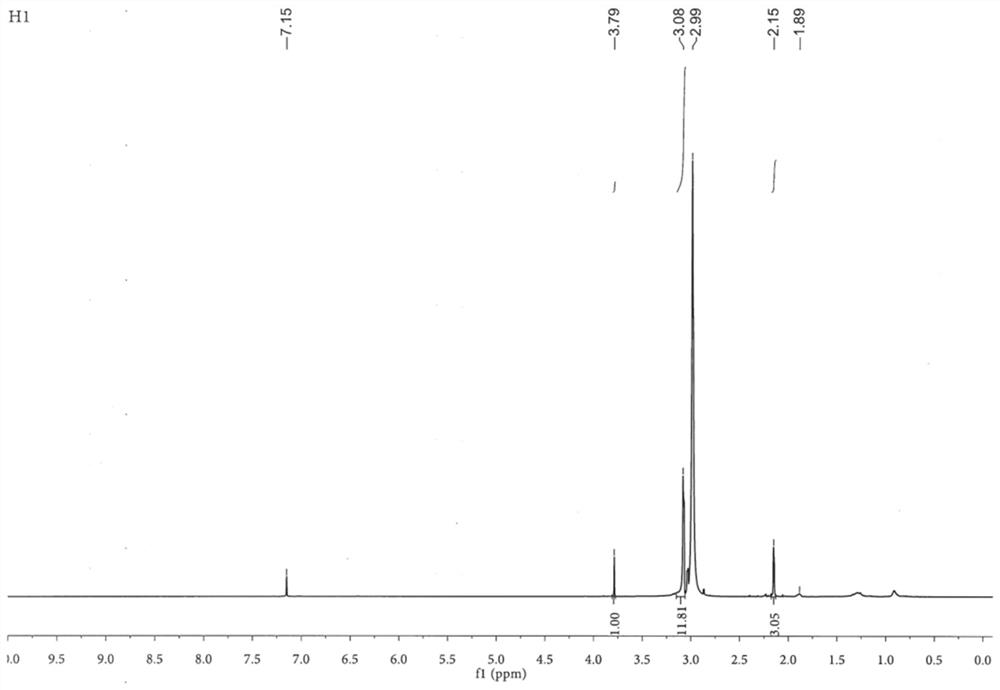

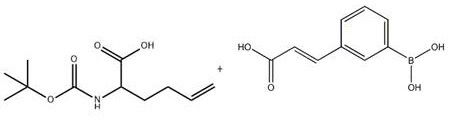

[0031] Described adsorption resin is a kind of surface graft modified adsorption resin, and its preparation method is:

[0032] Use an electron accelerator to irradiate 50g of D101 polystyrene macroporous adsorption resin with electron beams to generate active free radicals that can be used for grafting reactions. Irradiation c...

Embodiment 2

[0036] A method for refining tetrakis(dimethylamino) hafnium, the specific scheme is as follows:

[0037] Add 100g of tetrakis(dimethylamino)hafnium crude product into the refining reaction kettle, add 1.2g of adsorption resin under the protection of nitrogen, control the temperature at 35°C, stir and mix for 50min, filter and remove the adsorption resin, and then add tetrakis(dimethylamino)hafnium crude product Import it into a distillation kettle, control the temperature at 30°C, remove the volatile components under reduced pressure, then raise the temperature to 60°C, and distill under reduced pressure to obtain the refined tetrakis(dimethylamino)hafnium product.

[0038] Described adsorption resin is a kind of surface graft modified adsorption resin, and its preparation method is:

[0039] Use an electron accelerator to irradiate 60g of polystyrene macroporous adsorption resin with electron beams to generate active free radicals that can be used for grafting reactions. Irr...

Embodiment 3

[0043] A method for refining tetrakis(dimethylamino) hafnium, the specific scheme is as follows:

[0044] Add 120g of tetrakis(dimethylamino)hafnium crude product into the refining reaction kettle, add 3g of adsorption resin under the protection of nitrogen, control the temperature at 40°C, stir and mix for 90min, filter and remove the adsorption resin, and then introduce tetrakis(dimethylamino)hafnium crude product into Put it into a still, control the temperature at 35°C, remove the volatile components under reduced pressure, then raise the temperature to 50°C, and distill under reduced pressure to obtain the refined tetrakis(dimethylamino)hafnium product.

[0045] Described adsorption resin is a kind of surface graft modified adsorption resin, and its preparation method is:

[0046] Use an electron accelerator to irradiate 70g of polystyrene macroporous adsorption resin with electron beams to generate active free radicals that can be used for grafting reactions. Irradiation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com