Olefin polymerization catalyst solid component, preparation method thereof, olefin polymerization catalyst and application

A solid component, olefin polymerization technology, applied in the field of olefin polymerization catalysts and their applications, olefin polymerization catalyst solid components and their preparation fields, can solve problems such as the inability to meet the needs of industrial production, achieve good activity and copolymerization performance, The effect of high hydrogen modulation sensitivity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to the present invention, the above-mentioned olefin polymerization catalyst solid component can be prepared by various methods, preferably, according to the second aspect of the present invention, the preparation method of the olefin polymerization catalyst solid component comprises the following steps:

[0033] (1) under stirring, the alkoxymagnesium compound is dispersed in an inert solvent to form a suspension;

[0034] (2) Under stirring, the suspension is contacted with the internal electron donor halogenated hydrocarbon compound and aromatic ester compound, and the halide of transition metal titanium and / or its derivatives, and then solid-liquid separation and washing ;

[0035] Wherein, the general formula of the halogenated hydrocarbon compound is R m 1 x a R 2 n x b R 3 p x c , where R 1 , R 2 , R 3 each independently for C 1 -C 20 Alkyl, C 3 -C 20 alicyclic or C 6 -C 20 Aryl, m, n, p are each independently an integer of 0-10, but m...

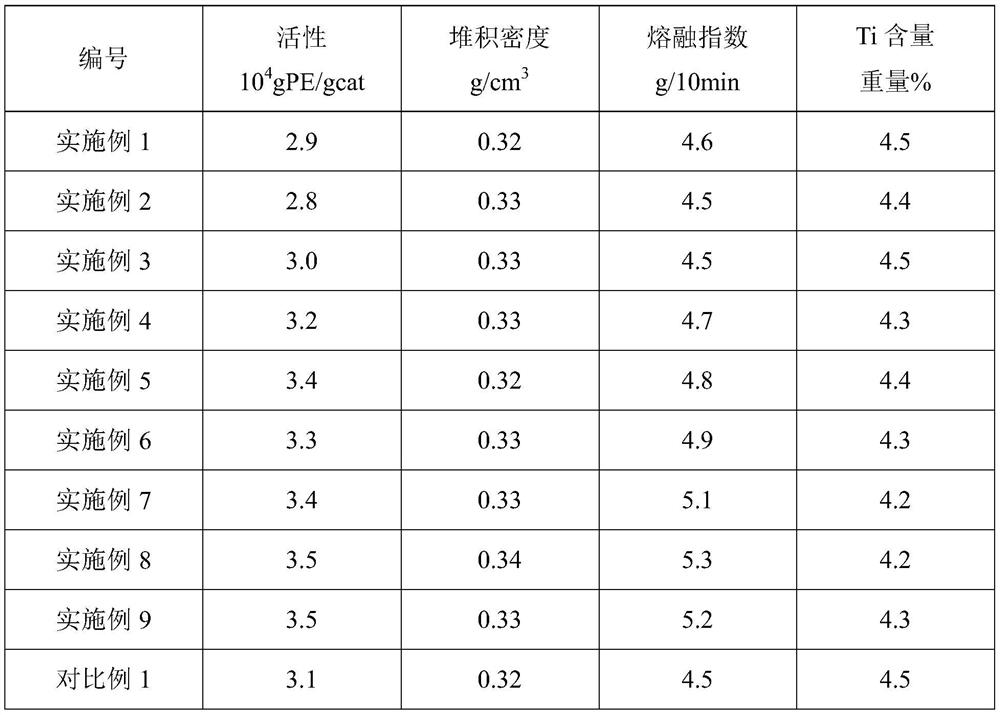

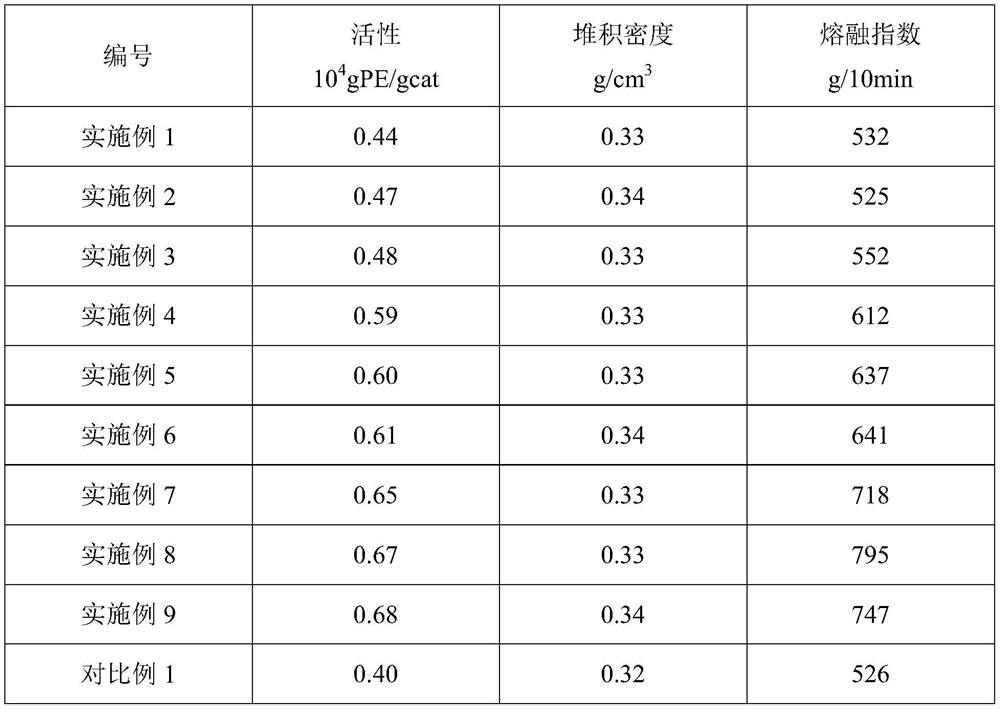

Embodiment 1

[0066] This example is used to illustrate the preparation of the solid component of the olefin polymerization catalyst provided by the present invention and the polymerization reaction using the obtained olefin polymerization catalyst.

[0067] (1) Preparation of olefin polymerization catalyst solid component A1

[0068] In the reactor fully replaced by high-purity nitrogen, 4.8 g of magnesium alkoxide and 60 mL of toluene were sequentially added to form a suspension at a stirring speed of 300 rpm. Cool the system down to -20°C, add 3ml of 1,2-dichloroethane and 2ml of ethyl benzoate in sequence, then add 40mL of titanium tetrachloride dropwise, keep the temperature for 30 minutes, raise the temperature to 80°C, and react for 2 hours . Stop stirring, let it stand, the suspension will be layered quickly, and the supernatant will be sucked out. Add 60 mL of toluene and 20 mL of titanium tetrachloride, raise the temperature to 80° C., and keep the temperature constant for 2 hou...

Embodiment 2

[0077] This example is used to illustrate the preparation of the solid component of the olefin polymerization catalyst provided by the present invention and the polymerization reaction using the obtained olefin polymerization catalyst.

[0078] (1) Preparation of olefin polymerization catalyst solid component A2

[0079] The olefin polymerization catalyst solid component A2 was prepared according to the method of Example 1, except that only 1,2-dichloroethane was replaced with 1,2,3-trichloropropane, and its composition is shown in Table 1.

[0080] (2) homopolymerization reaction

[0081] Homopolymerization was carried out according to the method of Example 1, except that the solid component of the olefin polymerization catalyst was the solid component A2 of the olefin polymerization catalyst prepared in this example, and the polymerization results are shown in Table 1 and Table 2.

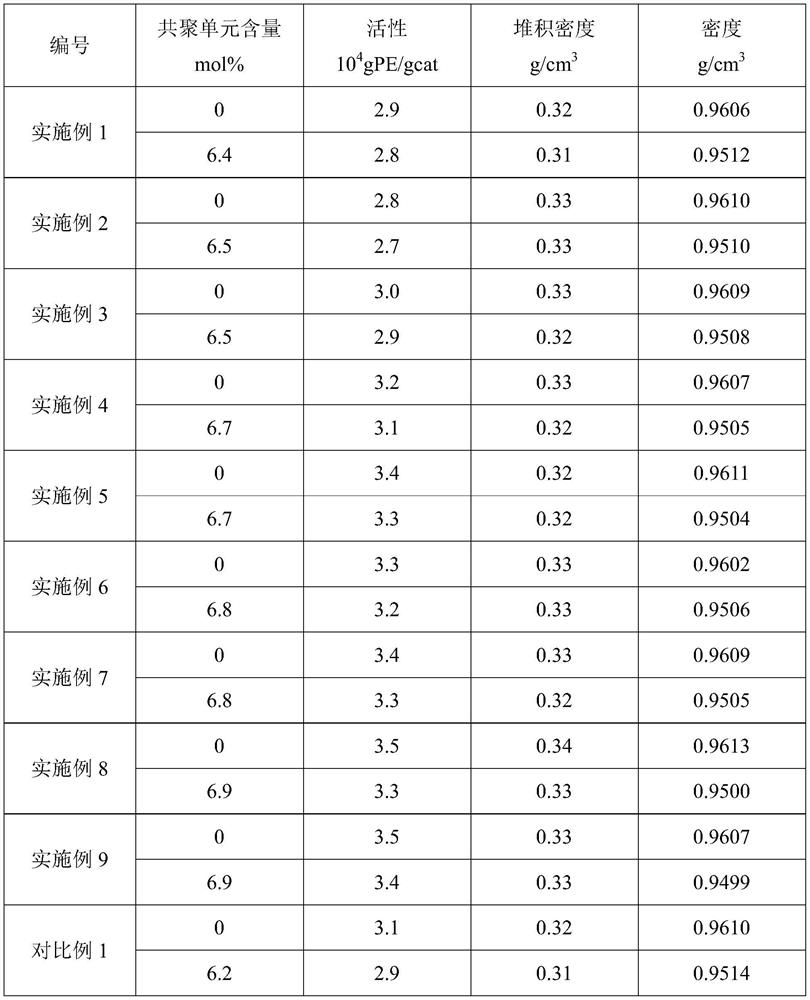

[0082] (3) Copolymerization reaction

[0083] The copolymerization reaction was carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com