Liquid crystal alignment agent and preparation method thereof, liquid crystal alignment film and preparation method thereof, liquid crystal cell

A liquid crystal aligning agent and solvent technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of liquid crystal display charge accumulation and other problems, achieve low residual voltage, improve reliability and stability, and improve the ability to release residual charges effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

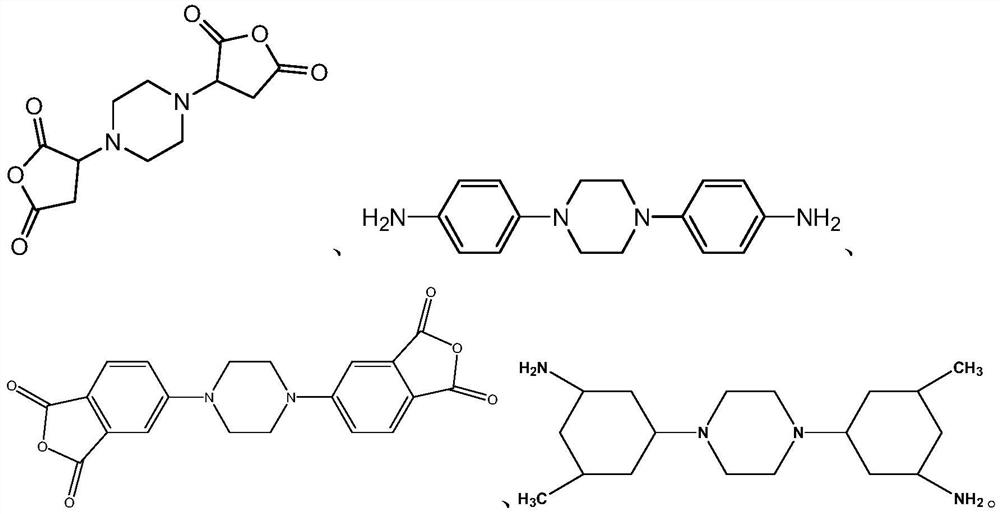

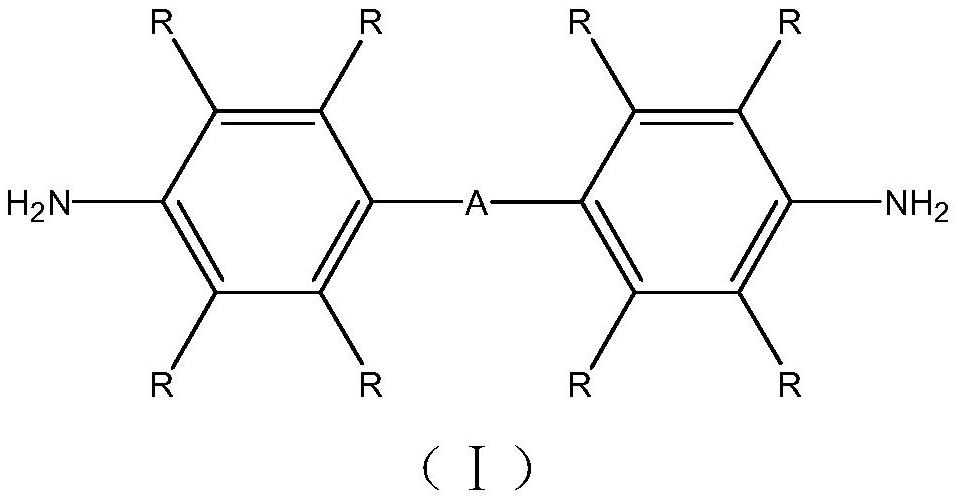

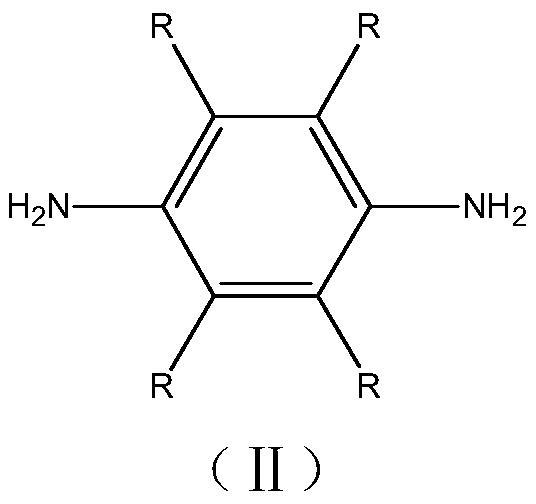

Method used

Image

Examples

Embodiment 1

[0083] (1) Preparation of polyamic acid liquid crystal alignment agent

[0084] At room temperature, under a nitrogen atmosphere, add 6.48 g (0.06 mol) of DN-1, 3.76 g (0.01 mol) of DN-2, 8.04 g (0.03 mol) of DN-4 and 88.4 g of NMP in sequence, stir at room temperature for 30 minutes, and confirm completely dissolved. Add 19.6 g (0.1 mol) of DA-1, and stir at room temperature for 3 hours to react, and the reaction solid content is 30%. After the reaction, dilute with 208.3 grams of NMP and 296.7 grams of BC to obtain a transparent viscous polyamic acid solution with a solid content of 6% and a solvent ratio of NMP / BC=50 / 50.

[0085] (2) Preparation of liquid crystal alignment film and liquid crystal cell

[0086] The polyamic acid liquid crystal alignment agent solution prepared by the above preparation method is evenly spin-coated on clean ITO glass, and then the ITO glass substrate is pre-baked at a temperature of 60-120°C for 10-20min, and then heated at a temperature of ...

Embodiment 2

[0088] (1) Preparation of polyamic acid liquid crystal alignment agent

[0089] At room temperature, under a nitrogen atmosphere, DN-1 9.72 g (0.09 mol), DN-2 3.76 (0.01 mol) and NMP 83.2 g were sequentially added, and stirred at room temperature for 30 minutes to confirm complete dissolution. Then 13.72 g (0.07 mol) of DA-1 and 8.46 g (0.03 mol) of DA-3 were added in sequence, stirred and reacted at room temperature for 3 hours, and the solid content of the reaction was 30%. After the reaction, dilute with 196.1 g of NMP and 279.3 g of BC to obtain a transparent viscous polyamic acid solution with a solid content of 6% and a solvent ratio of NMP / BC=50 / 50.

[0090] (2) Preparation of liquid crystal alignment film and liquid crystal cell

[0091] The polyamic acid liquid crystal alignment agent solution prepared by the above preparation method is evenly spin-coated on clean ITO glass, and then the ITO glass substrate is pre-baked at a temperature of 60-120°C for 10-20min, and ...

Embodiment 3

[0093] (1) Preparation of polyamic acid liquid crystal alignment agent

[0094] At room temperature, under a nitrogen atmosphere, add 5.4 g (0.05 mol) of DN-1, 10.44 g (0.02 mol) of DN-3, 8.04 g (0.03 mol) of DN-4 and 101.4 g of NMP, and stir at room temperature for 30 minutes to confirm completely dissolved. Add 19.6 g (0.1 mol) of DA-1, and stir at room temperature for 3 hours to react, and the reaction solid content is 30%. After the reaction, dilute with 39.1 grams of NMP2 and 340.6 grams of BC to obtain a transparent viscous polyamic acid solution with a solid content of 6% and a solvent ratio of NMP / BC=50 / 50.

[0095] (2) Preparation of liquid crystal alignment film and liquid crystal cell

[0096] The polyamic acid liquid crystal alignment agent solution prepared by the above preparation method is evenly spin-coated on clean ITO glass, and then the ITO glass substrate is pre-baked at a temperature of 60-120°C for 10-20min, and then heated at a temperature of 200-250°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com