Hot melt adhesive, preparation method thereof and wire head insulation method

A hot-melt adhesive and wire tip technology, which is used in conductor/cable insulation, adhesives, adhesive additives, etc., can solve the problems affecting the welding effect of the wire tip, residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

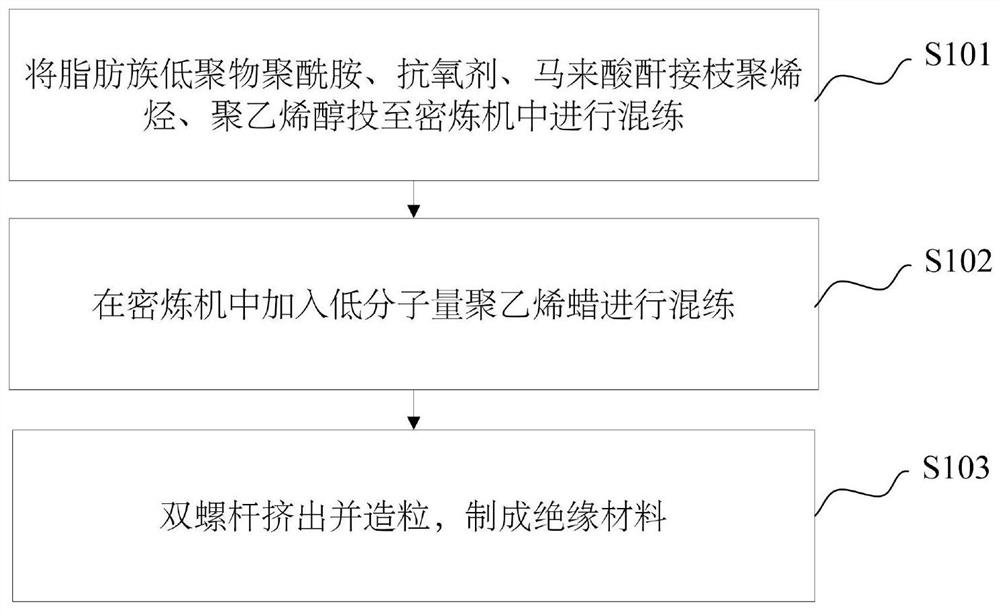

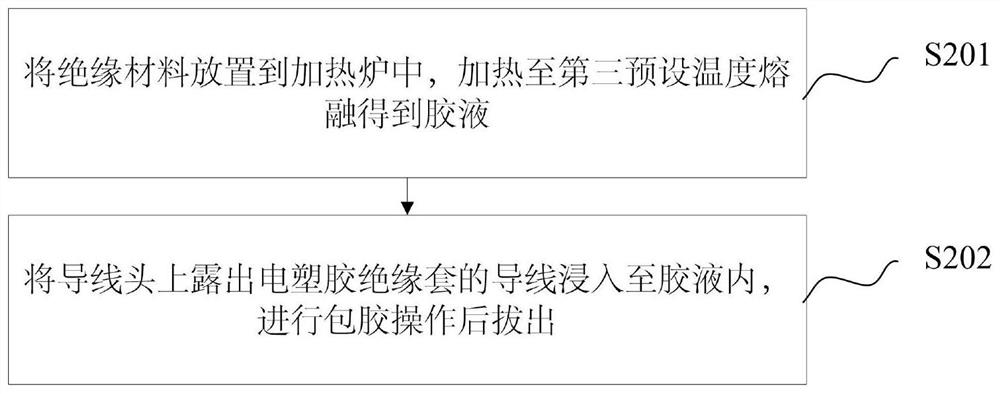

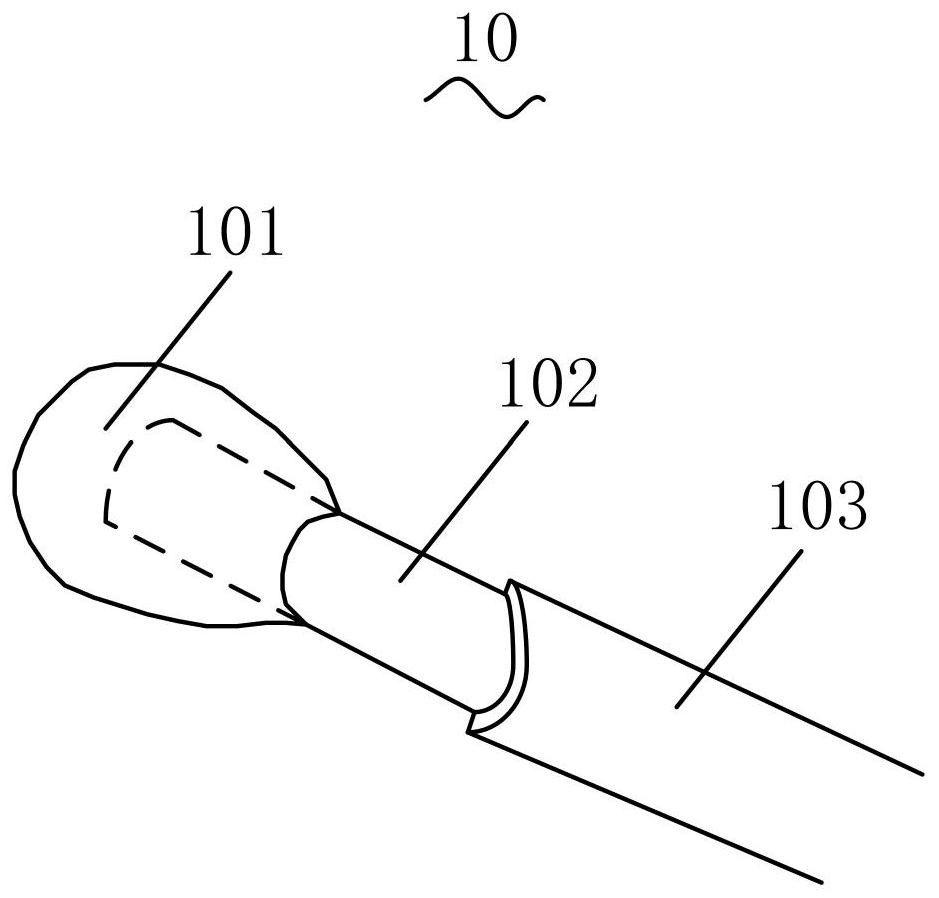

[0024] The following will clearly and completely describe the technical solutions of each exemplary embodiment provided in the present application with reference to the accompanying drawings in the embodiments of the present application. In the case of no conflict, the following embodiments and technical features thereof can be combined with each other.

[0025] The application provides a hot melt adhesive, which is made by mixing aliphatic polyamide, polyethylene wax, antioxidant, maleic anhydride grafted polyolefin and polyvinyl alcohol.

[0026] For aliphatic polyamides, polyamides are commonly known as nylon (Nylon), the English name Polyamide (abbreviated as PA), and the density is 1.15g / cm3. Family PA, aliphatic-aromatic PA and aromatic PA. Among them, aliphatic PA has many varieties, large output and wide application. The softening point of the aliphatic polyamide in the examples of the present application is 90-140°C, the melting temperature is 120-170°C, and the mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com