Multi-functional composite reinforcing agent for papermaking and preparation method thereof

A composite reinforcement and multi-functional technology, applied in the field of papermaking, which can solve the problems of limited effect of paper strength enhancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

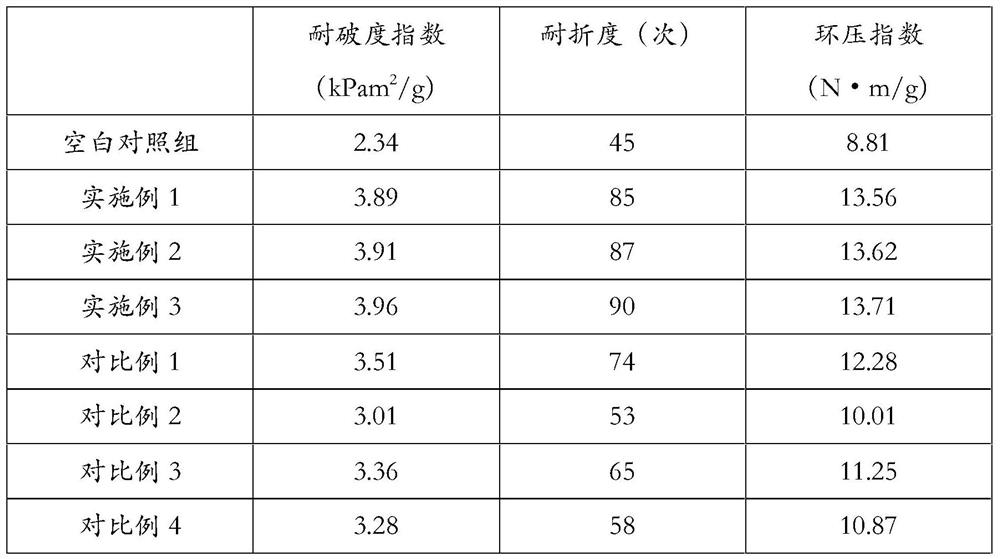

Examples

Embodiment 1

[0036] A preparation method of a composite reinforcing agent for multifunctional papermaking, the specific steps are as follows:

[0037] (1) First, halloysite nanotubes and aluminum nitrate are used as raw materials to prepare doped halloysite nanotubes, and then modified by gamma-aminoethylaminopropyltrimethoxysilane to obtain modified nanomaterials, spare;

[0038] (2) Using methylolacrylamide as a raw material, prepare gel-like polymethylolacrylamide through inverse emulsion polymerization;

[0039] (3) The starch is then formulated into a starch slurry, and then the polymethylolacrylamide obtained in step (2) is added for grafting reaction to obtain a grafted starch slurry, and then 3-chloro-2-hydroxypropyl-trimethoxy Ammonium chloride is carried out etherification modification, obtains modified starch slurry;

[0040] (4) Finally, add the modified nanomaterial and coniferyl alcohol obtained in step (1) into the modified starch slurry obtained in step (3), and stir for ...

Embodiment 2

[0052] A preparation method of a composite reinforcing agent for multifunctional papermaking, the specific steps are as follows:

[0053] (1) First, halloysite nanotubes and aluminum nitrate are used as raw materials to prepare doped halloysite nanotubes, and then modified by gamma-aminoethylaminopropyltrimethoxysilane to obtain modified nanomaterials, spare;

[0054] (2) Using methylolacrylamide as a raw material, prepare gel-like polymethylolacrylamide through inverse emulsion polymerization;

[0055] (3) The starch is then formulated into starch slurry, then the polymethylolacrylamide obtained in step (2) is added, and grafted to obtain a grafted starch slurry, and then 3-chloro-2-hydroxypropyl-trimethoxy Ammonium chloride is carried out etherification modification, obtains modified starch slurry;

[0056] (4) Finally, add the modified nanomaterial and coniferyl alcohol obtained in step (1) into the modified starch slurry obtained in step (3), and stir for reaction to obt...

Embodiment 3

[0068] A preparation method of a composite reinforcing agent for multifunctional papermaking, the specific steps are as follows:

[0069] (1) First, halloysite nanotubes and aluminum nitrate are used as raw materials to prepare doped halloysite nanotubes, and then modified by gamma-aminoethylaminopropyltrimethoxysilane to obtain modified nanomaterials, spare;

[0070] (2) Using methylolacrylamide as a raw material, prepare gel-like polymethylolacrylamide through inverse emulsion polymerization;

[0071] (3) The starch is then formulated into starch slurry, then the polymethylolacrylamide obtained in step (2) is added, and grafted to obtain a grafted starch slurry, and then 3-chloro-2-hydroxypropyl-trimethoxy Ammonium chloride is carried out etherification modification, obtains modified starch slurry;

[0072] (4) Finally, add the modified nanomaterial and coniferyl alcohol obtained in step (1) into the modified starch slurry obtained in step (3), and stir for reaction to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com