Nano-robot with anti-tumor function and preparation method thereof

A nanorobot, anti-tumor technology, applied in the field of nanomaterials, can solve the problems of poor stability of nanorobot preparation process, poor tumor treatment effect, and poor product size uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

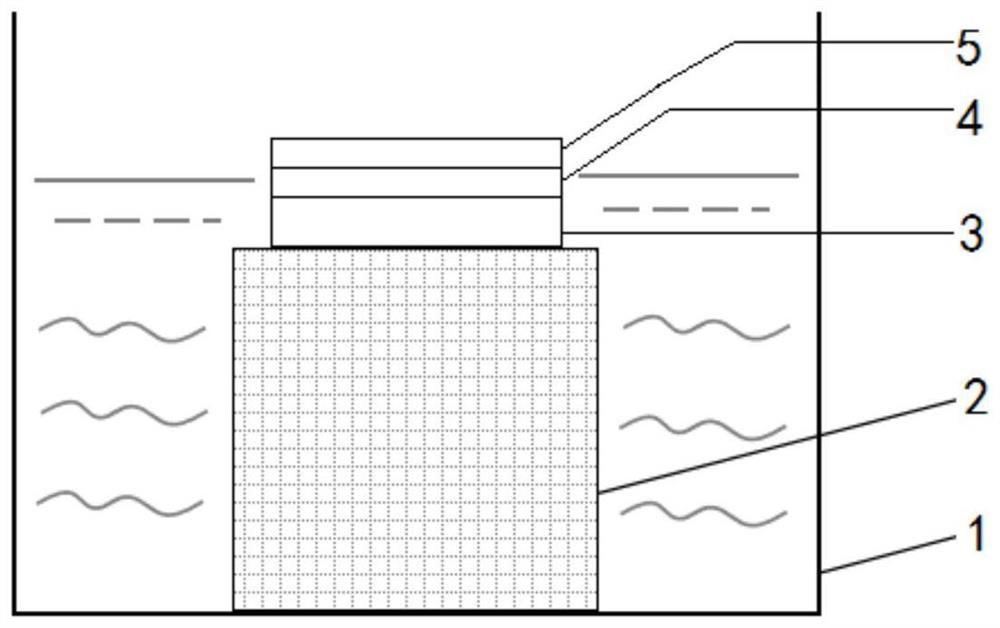

[0032] The invention provides a method for preparing a nanorobot with anti-tumor function, comprising the following steps:

[0033] a) mixing magnetic magnesium alloy nanoparticles, antineoplastic drugs, polylactic acid and a volatile organic solvent to obtain a mixed solution;

[0034] b) mixing the mixed solution with water and stirring to evaporate the volatile organic solvent in the mixed system to obtain a suspension;

[0035] c) centrifuging the suspension and discarding the supernatant to obtain a nanorobot with anti-tumor function.

[0036] In the preparation method provided by the present invention, magnetic magnesium alloy nanoparticles are firstly provided. Wherein, the chemical composition of the magnetic magnesium alloy particles preferably includes Nd, Fe, SiO 2 , Mn, Zn and Mg; the content of the Nd in the magnetic magnesium alloy particles is preferably 3 to 5wt%, specifically 3wt%, 3.5wt%, 4wt%, 4.5wt% or 5wt%; the Fe in the magnetic The content in the magn...

Embodiment 1

[0070] 1) Preparation of magnetic magnesium alloy nanoparticles

[0071] 1.1) Cleaning: Wipe the glass substrate substrate with a size of 300mm×400mm×0.5mm with alcohol, then put it into an ultrasonic cleaner, super-wash with deionized water, super-wash with alcohol, and finally dry the substrate in alcohol vapor , When the substrate is taken out from the steam, the substrate can be dried quickly because the condensed steam evaporates from the surface. In this embodiment, the ultrasonic power in each of the above ultrasonic processes is 150W.

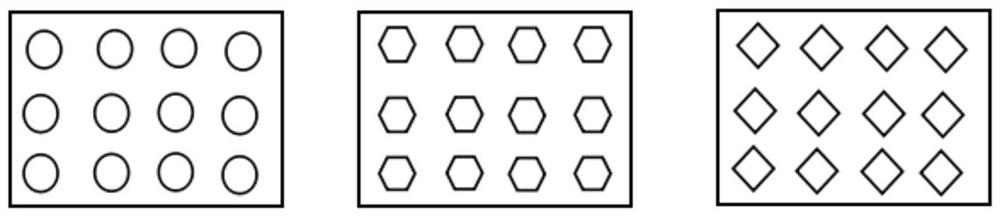

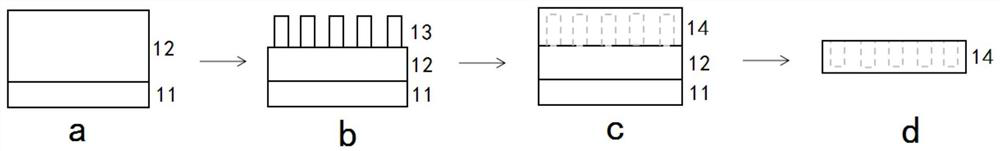

[0072] 1.2) Spin-coated gelatin film layer: place the glass substrate in the worktable of the automatic knife scraper spin-coating machine, automatically position it, and automatically scrape a thin layer of gelatin film layer by the centrifugal law. The rotary scraping speed is 1200rpm. The scraping time is 12 seconds, the uniformity is controlled within ±3%, and then placed in a drying oven at 25±1°C to dry and form a film; the worki...

Embodiment 2

[0090] 1) Preparation of magnetic magnesium alloy nanoparticles

[0091] 1.1) Cleaning: Wipe the glass substrate substrate with a size of 300mm×400mm×0.5mm with alcohol, then put it into an ultrasonic cleaner, super-wash with deionized water, super-wash with alcohol, and finally dry the substrate in alcohol vapor , When the substrate is taken out from the steam, the substrate can be dried quickly because the condensed steam evaporates from the surface. In this embodiment, the ultrasonic power in each of the above ultrasonic processes is 150W.

[0092] 1.2) Spin-coated gelatin film layer: place the glass substrate in the worktable of the automatic knife scraper spin-coating machine, automatically position it, and automatically scrape a thin layer of gelatin film layer by the centrifugal law. The rotary scraping speed is 1000rpm. The scraping time is 10 seconds, the uniformity is controlled within ±3%, and then placed in a drying oven at 25±1°C to dry and form a film; the worki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com