Self-brazing flux aluminum brazing filler metal plate and manufacturing method thereof

A production method and technology of aluminum brazing material, applied in the direction of manufacturing tools, welding/cutting media/materials, welding media, etc., can solve the problems of reducing welding strength, etc., to prevent oxidation, improve the utilization rate of raw materials, and good brazing activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Make self-fluxing aluminum brazing material according to the following steps.

[0069] (1) The solder used is an Al-Si base alloy, wherein the Si content is 6%; the solder used is potassium fluoroaluminate (K 3 AlF 6 ), prepare self-fluxing aluminum solder composite powder according to the following conditions:

[0070] Brazing filler metal flow rate 7.5kg / min metal temperature 720℃ Particle velocity 0.32kg / min Flux powder temperature 20℃ atomizing gas Nitrogen

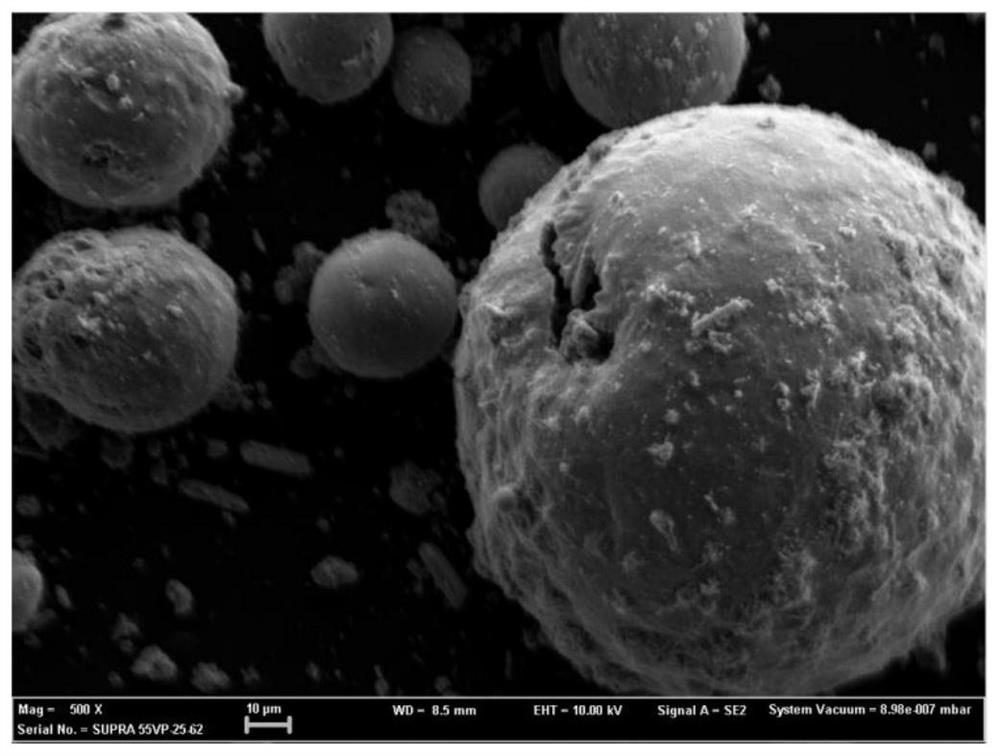

[0071] The specific process is as follows: melt the Al-Si-based alloy at about 720°C to form an alloy melt; the Al-Si-based alloy melt forms a stream, and flows into the nitrogen atmosphere atomization chamber at a flow rate of 7.5kg / min; guided by the atomization nozzle Nitrogen gas is sprayed on the Al-Si-based alloy melt stream to produce a molten or semi-solidified melt droplet jet flow of the Al-Si-based alloy; nitrogen gas flow is used to blow potassium fluoroal...

Embodiment 2

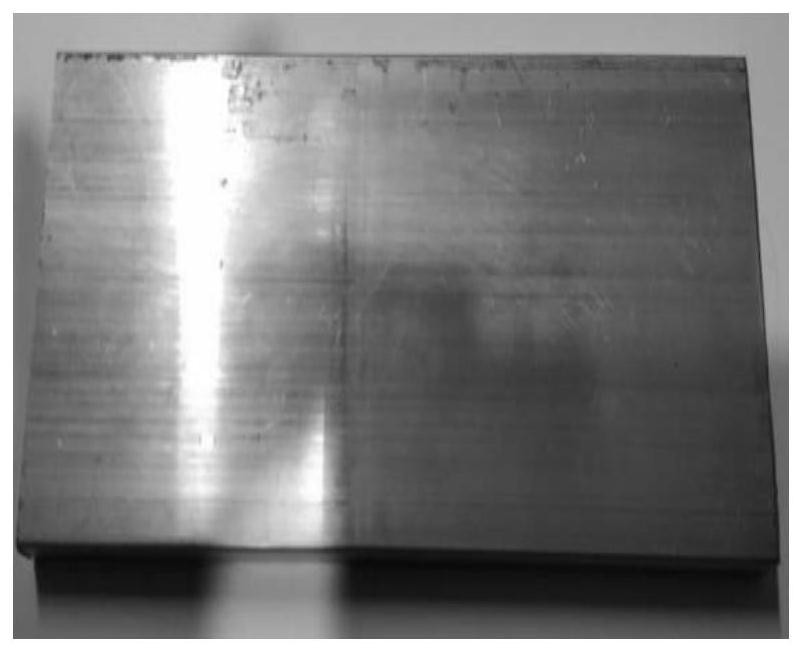

[0091] By the same steps as in Example 1, a self-fluxing aluminum brazing filler metal plate of 400 mm long × 300 mm wide × 80 mm thick was produced, delivered to Shanghai Huafeng Aluminum Co., Ltd., and rolled and connected with 3003 aluminum alloy plates to produce Composite tubes for heat exchangers, and brazing experiments for tubes and fins of heat exchangers, and Shanghai Huafeng Aluminum Co., Ltd. inspected and tested the products.

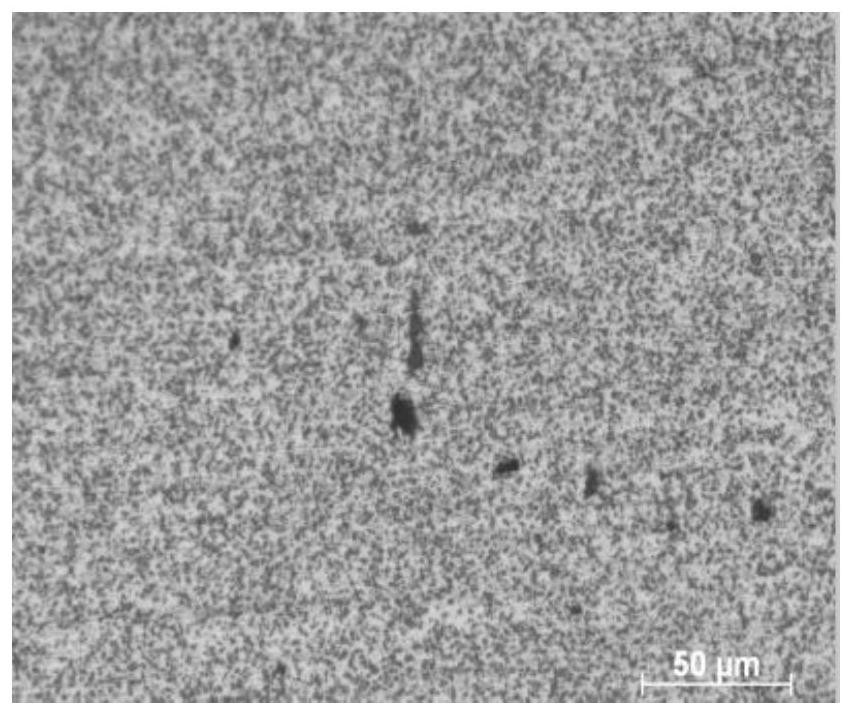

[0092] The composite pipe produced by the rolling and pressing connection process is composed of a core layer of double-layer cladding, that is, the core layer of 3003 aluminum alloy is sandwiched between the self-fluxing solder layers of the present invention, wherein the total thickness of the composite plate is 0.6mm, the upper and lower self-fluxing aluminum solder layers account for 5% of the total thickness (that is, each 0.03mm). Silicon grain distribution, image 3 Show the self-fluxing aluminum brazing filler metal sheet material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com