Method and system for purifying and recycling waste sulfuric acid

A technology of waste sulfuric acid and sulfuric acid, which is applied in chemical instruments and methods, sulfur compounds, sulfur trioxide/sulfuric acid, etc., and can solve the problems of waste sulfuric acid solution discharge pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

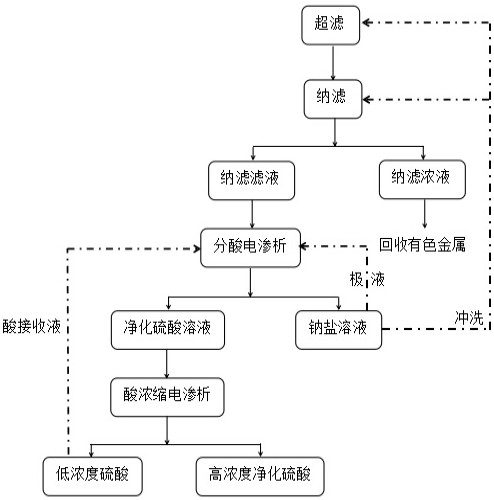

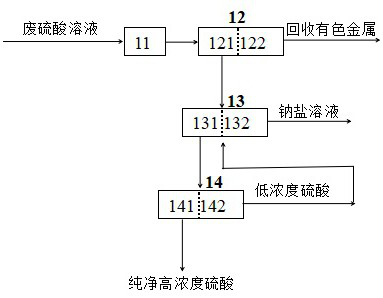

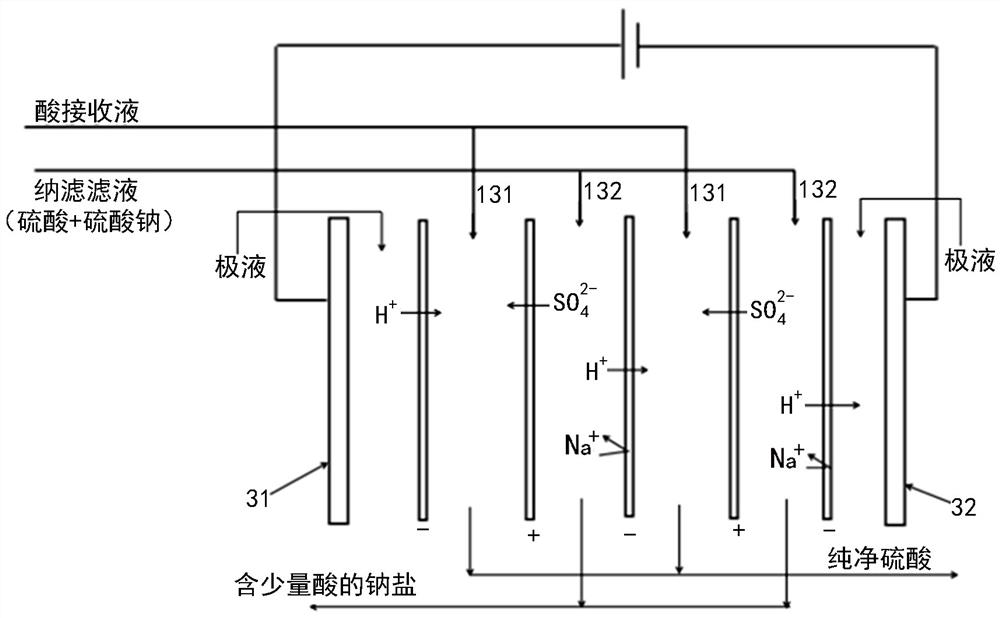

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the waste sulfuric acid solution contains 2.7% sulfuric acid, 5.9% copper ions, and 2.1% sodium ions, and is a waste sulfuric acid solution for metal smelting. Among them, ultrafiltration adopts a ceramic ultrafiltration membrane with a filter pore size of 10 nm. The acid-resistant nanofiltration membrane is used in the nanofiltration separation, and the nanofiltration filtrate tube is chlorinated polyvinyl chloride. The cation exchange membrane in the acid separation electrodialysis treatment adopts the acid separation selective ion exchange membrane, the selective permeability is 98.5%, and the membrane resistance is 2.5Ω·cm 2 , the current density is 400A / m 2 ; In the acid concentration electrodialysis treatment, a special acid concentration homogeneous ion exchange membrane is used, with a selective transmission rate of 98% and a membrane resistance of 1.5Ω·cm 2 , the current density is 500A / m 2 ; After the above treatment, 18.9% purified sulf...

Embodiment 2

[0049] In this embodiment, the waste sulfuric acid solution contains 4.3% sulfuric acid, 6.8% nickel ions, and 3.5% sodium ions, which is the waste sulfuric acid solution for metal smelting. Among them, ultrafiltration adopts a ceramic ultrafiltration membrane with a filter pore size of 50 nm. The acid-resistant nanofiltration membrane is used in the nanofiltration separation, and the nanofiltration filtrate tube is chlorinated polyvinyl chloride; the cation exchange membrane in the acid separation electrodialysis treatment adopts an acid separation selective ion exchange membrane, the selective transmission rate is 97%, and the membrane resistance is 4.5Ω·cm 2 , the current density is 250A / m 2 ; In the acid concentration electrodialysis treatment, a special acid concentration homogeneous ion exchange membrane is used, with a selective permeability of 98% and a membrane resistance of 3 Ω·cm 2 , with a current density of 320 A / m 2 ; After the above treatment, 22.7% of purifi...

Embodiment 3

[0051] In this embodiment, the waste sulfuric acid solution contains 5.5% sulfuric acid, 3.6% cobalt ions, and 2.9% sodium ions, which is the waste sulfuric acid solution for metal smelting. Among them, the ceramic ultrafiltration membrane with a filter aperture of 20nm is used for ultrafiltration; acid-resistant nanofiltration membrane is used in nanofiltration separation, and the nanofiltration filtrate tube is chlorinated polyvinyl chloride; the cation exchange membrane in acid separation electrodialysis treatment uses acid to separate selective ions Exchange membrane with a selective transmittance of 96.5% and a membrane resistance of 3Ω·cm 2 , the current density is 350A / m 2 ; In the acid concentration electrodialysis treatment, a special acid concentration homogeneous ion exchange membrane is used, with a selective transmission rate of 98.5% and a membrane resistance of 2 Ω·cm 2 , the current density is 450A / m 2 ; After the above treatment, 20.6% purified sulfuric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com