Inorganic perovskite material, preparation method thereof and LED device

An inorganic calcium and LED chip technology, applied in inorganic chemistry, luminescent materials, semiconductor devices, etc., can solve problems affecting product crystallinity, fluorescence yield and phase purity, and achieve low cost of raw materials, simple synthesis operations, and fluorescence yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

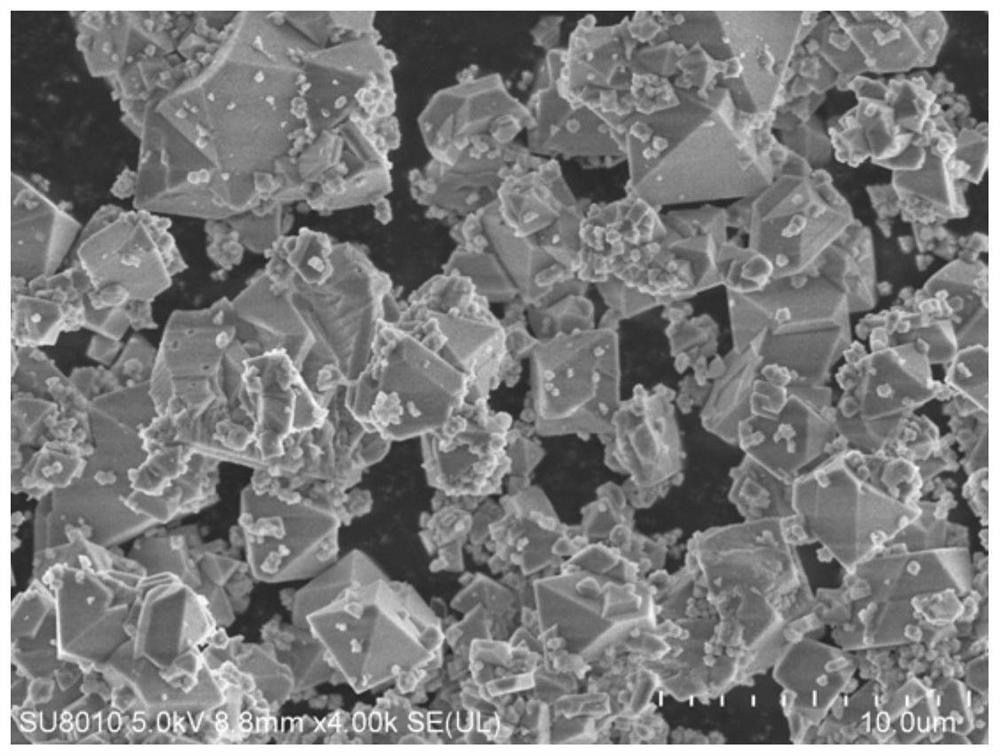

Embodiment 1

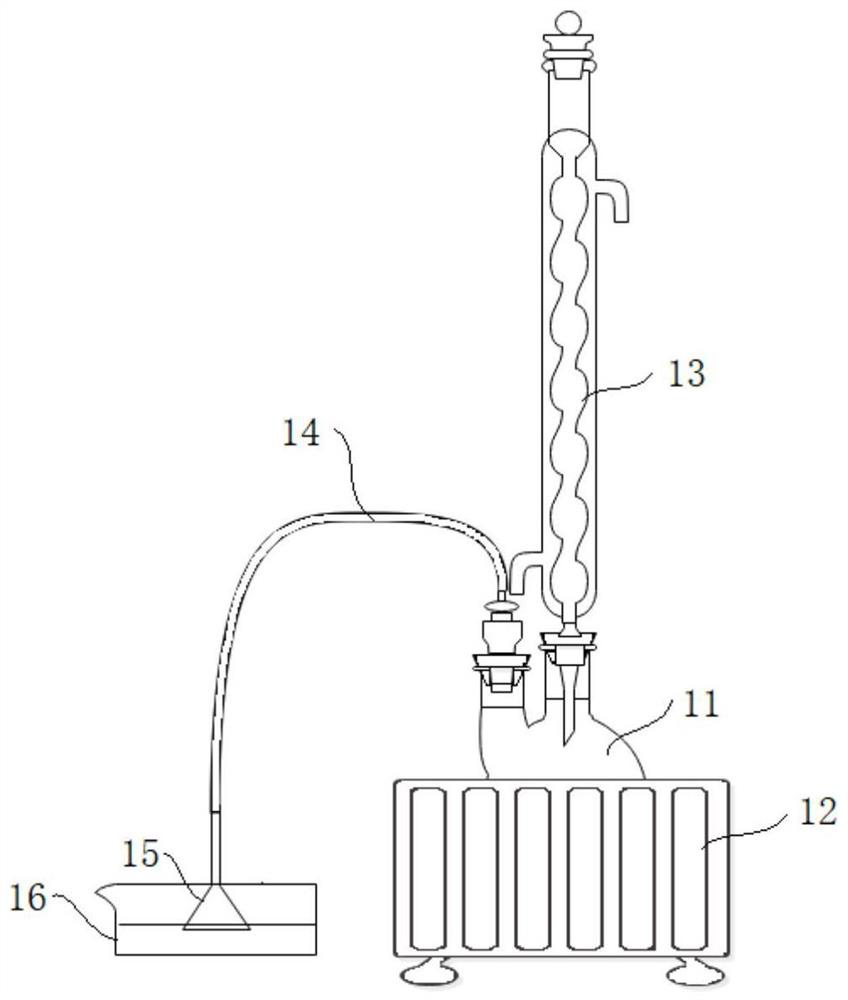

[0037] An inorganic perovskite material, specifically adopting a liquid phase method in figure 1 Prepare and synthesize in the reaction system shown, its concrete preparation method comprises the following steps:

[0038]S1, take by weighing 0.6734g cesium chloride and 0.4010g stannous oxalate, 0.0189g bismuth chloride, put stannous oxalate and bismuth chloride in the double-necked glass flask 11, then inject 5mL concentrated hydrochloric acid thereinto, and put Rotate and stir the magnet; mix cesium chloride and 11ml concentrated hydrochloric acid in a small bottle, and heat the small bottle to 80°C for about 30 minutes in a water bath to obtain a cesium chloride-concentrated hydrochloric acid mixture;

[0039] S2. Put the double-necked glass flask 11 into the oil bath 12 with a heat-collecting constant temperature heating magnetic stirrer, the upper opening of the double-necked glass bottle 11 is connected to the condenser 13, and the side opening is connected to the funnel ...

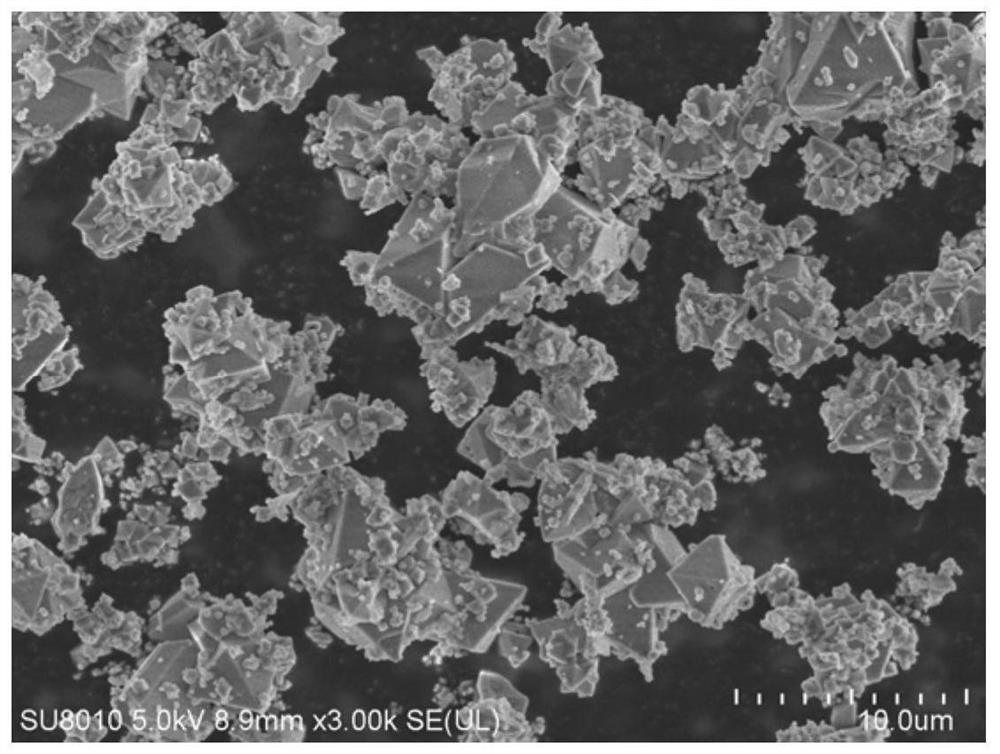

Embodiment 2

[0044] A kind of inorganic perovskite material, its concrete method comprises the following steps:

[0045] S1, take by weighing 0.6734g cesium chloride and 0.4514mg stannous chloride dihydrate, 0.0189g bismuth chloride, put stannous chloride dihydrate and bismuth chloride into the reaction glass bottle, then inject 5mL ethanol thereinto, Obtain the first mixture; then mix cesium chloride and 11ml of ethanol in a small bottle, and use a water bath to heat the small bottle to 60°C for about 30mins to obtain the second mixture;

[0046] S2. Then raise the temperature of the first mixture obtained in step S1 to 80°C under stirring, and the heating rate is 8°C / min. When the sample is heated to 80°C, open the side opening and pour the second mixture into the reaction glass bottle middle. Close the side opening, and then keep warm for 3 hours;

[0047] S3. After the reaction is completed, the temperature of the material is lowered to room temperature, and the solid product is take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com