Fly ash resource utilization treatment system and method

A processing system and resource-based technology, applied in the field of environmental protection, can solve the problems of insufficient utilization of steam, large steam consumption, and high processing cost, and achieve the effects of low equipment cost, high degree of automation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

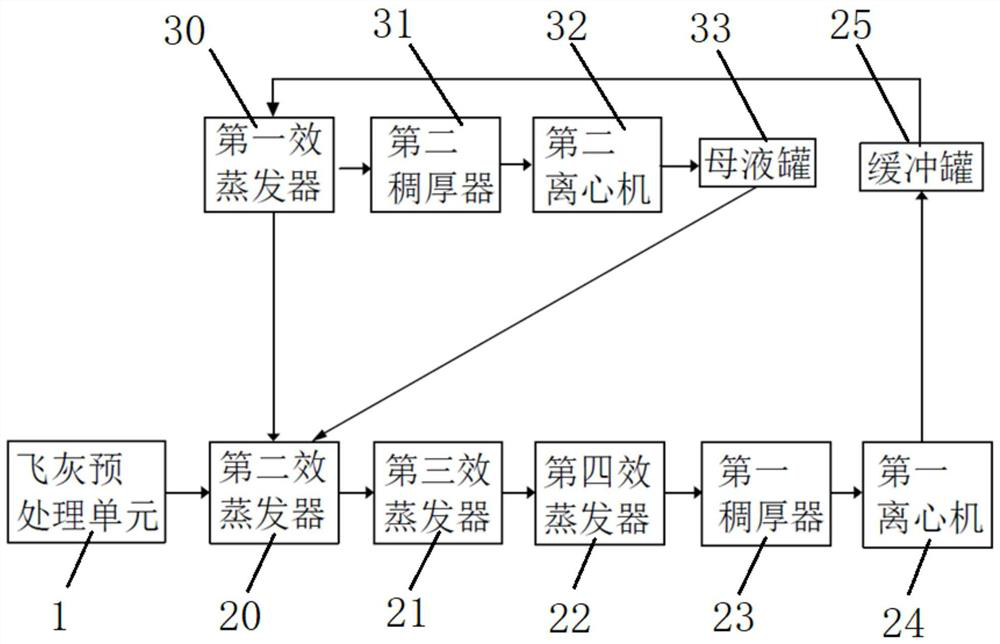

[0035] A fly ash resource utilization processing system, such as figure 1 As shown, the system includes a fly ash pretreatment unit 1, a first evaporative crystallization unit and a second evaporative crystallization unit; the first evaporative crystallization unit includes three evaporators, a first thickener 23, a first centrifuge 24 and a buffer tank 25. The second evaporative crystallization unit includes an evaporator, a second thickener 31, a second centrifuge 32 and a mother liquor tank 33;

[0036] The evaporator in the second evaporative crystallization unit and the evaporator in the first evaporative crystallization unit jointly form a four-effect evaporator; the evaporator in the second evaporative crystallization unit is the first effect evaporator 30, and The evaporators are the second, third and fourth effect evaporators, the fly ash pretreatment unit 1 is connected to the second effect evaporator 20, the second effect evaporator 20 is connected to the third effe...

Embodiment 2

[0040] A fly ash resource utilization treatment system, the system includes a fly ash pretreatment unit, a first evaporation crystallization unit and a second evaporation crystallization unit; the first evaporation crystallization unit includes three evaporators, a first thickener, a first centrifuge Machine and buffer tank, the second evaporative crystallization unit includes two evaporators, the second thickener, the second centrifuge and the mother liquor tank;

[0041] The evaporator in the second evaporation crystallization unit and the evaporator in the first evaporation crystallization unit together form a five-effect evaporator; the evaporator in the second evaporation crystallization unit is the first and second effect evaporators, and the first evaporation crystallization unit The evaporators are the third, fourth and fifth effect evaporators, the fly ash pretreatment unit is connected with the third effect evaporator, the third effect evaporator is connected with the...

Embodiment 3

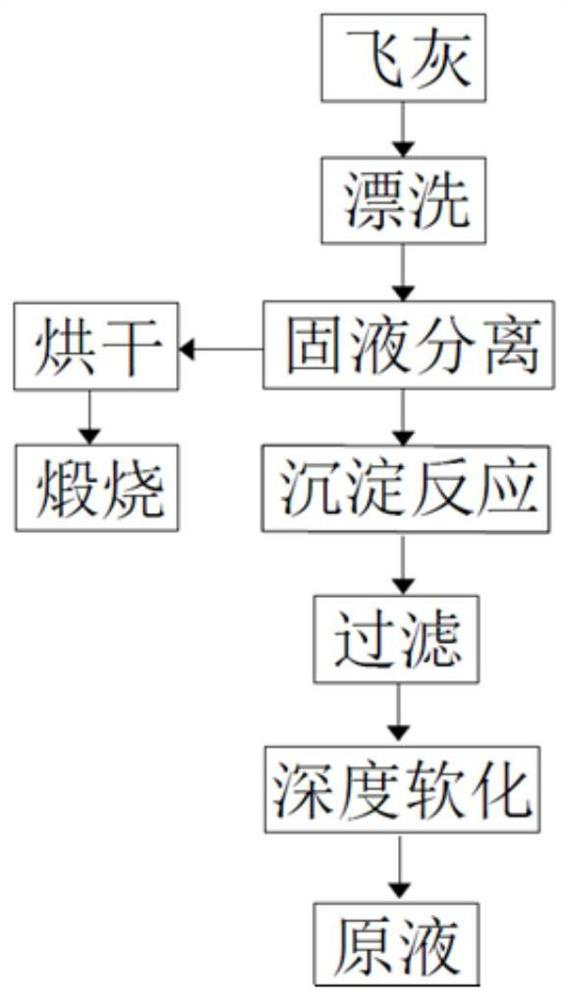

[0044] A method of utilizing the fly ash resource utilization processing system in Embodiment 1 to carry out fly ash resource utilization processing method, such as image 3 shown, including the following steps:

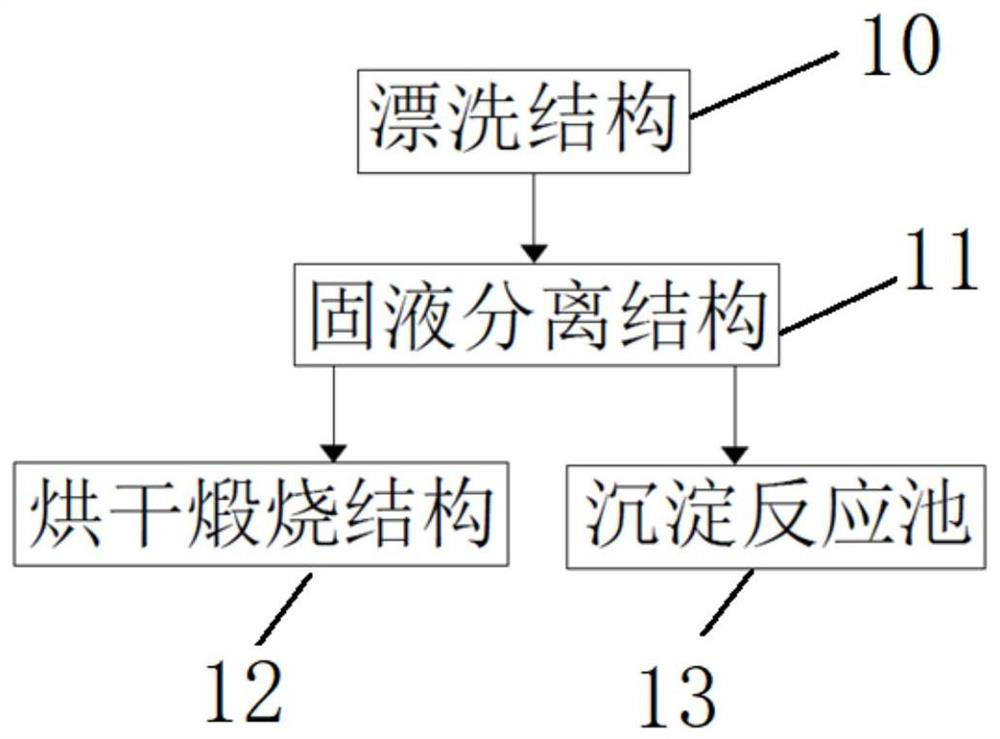

[0045] (1) The potassium-rich and low-sodium fly ash produced by waste incineration is subjected to multi-stage gradient countercurrent washing through the rinsing structure 10, and solid-liquid separation is carried out to obtain wet mud and fly ash washing water; the wet mud is dried and calcined, solidified, and fly ash The ash washing water passes through the precipitation reaction tank 13, and sodium sulfide is added to the precipitation reaction tank 13 to remove the precipitate, then sodium hydroxide and sodium carbonate are added to precipitate the impurity metal ions, filtered, and the filtrate is passed through a primary ion exchange resin to obtain the original solution ;

[0046] (2) The stoste is sent into the first evaporative crystallization unit, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com