Multi-metal carbide modified carbon-based material and preparation method thereof

A multi-metal, carbon-based material technology, applied in electrical components, spark gaps, spark gap parts, etc., can solve the problems of high discharge ablation volume rate, poor bonding strength, and difficult preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention proposes a method for preparing a carbon-based material modified by a multi-element metal carbide, comprising the following steps:

[0040] S1: Use metal Hf as the reaction source, metal fluoride mixture as the active agent, and the mixed salt of NaCl and KCl as the molten salt medium;

[0041] Weighing the metal elemental Hf, the metal fluoride mixture and the mixed salt of NaCl and KCl, and mixing them uniformly to obtain the mixture;

[0042] The metal fluoride mixture includes two or three metal fluorides of different metals, and the metal fluoride is K 2 TiF 6 、K 2 ZrF 6 and K 2 TaF 7 at least two of the

[0043] S2: using graphite as a matrix, placing the graphite and the mixture in a vacuum furnace;

[0044] Graphite is washed and dried before use. The shape of the graphite matrix is not limited in any way, its size is only limited by the size of the container and furnace chamber used.

[0045] S3: Repeatedly evacuate the vacuum f...

Embodiment 1

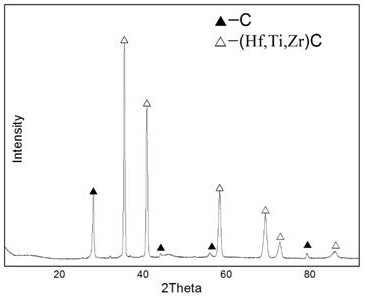

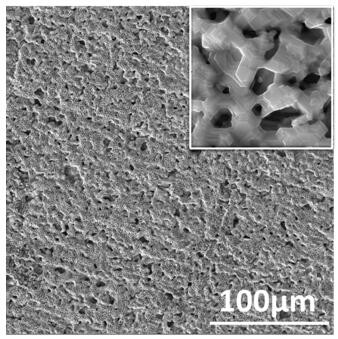

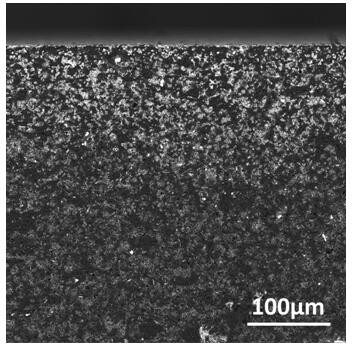

[0066] This embodiment provides a carbon-based material modified by a multi-element metal carbide, which is a (Hf, Zr, Ti) C coating on the surface of a graphite substrate. The (Hf, Zr, Ti) C coating is mainly passed on the graphite substrate. Formed by the disproportionation reaction of molten salt, the (Hf, Zr, Ti) C fills the surface and internal pores of the graphite matrix.

[0067] In this embodiment, the (Hf, Zr, Ti)C has a decreasing quantity gradient from the surface of the graphite matrix to the interior of the graphite matrix, and the penetration depth of (Hf, Zr, Ti)C into the interior of the graphite matrix is about 200 μm.

[0068] This embodiment also provides a method for preparing the above-mentioned multi-element metal carbide modified carbon-based material, comprising the following steps:

[0069] (1) The graphite sample was ultrasonically cleaned with ethanol for 10 minutes, then ultrasonically cleaned with deionized water for 5 minutes, and then dried at...

Embodiment 2

[0079] This embodiment provides a carbon-based material modified by a multi-element metal carbide, which is a (Hf, Ti, Ta) C coating on the surface of a graphite substrate. The (Hf, Ti, Ta) C coating is mainly passed on the graphite substrate. Formed by the disproportionation reaction of molten salt, the (Hf,Ti,Ta)C is filled in the pores on the surface and inside of the graphite matrix.

[0080] In this embodiment, the (Hf, Ti, Ta)C has a composition gradient from the surface of the graphite matrix to the interior of the graphite matrix, and the penetration depth of (Hf, Ti, Ta)C into the interior of the graphite matrix is about 80 μm.

[0081] This embodiment also provides a method for preparing the above-mentioned multi-element metal carbide modified carbon-based material, including:

[0082] (1) The graphite sample was ultrasonically cleaned with ethanol for 10 minutes, then ultrasonically cleaned with deionized water for 5 minutes, and then dried at 150°C for 60 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com