Gel polymer electrolyte, electrochromic gel prepared from gel polymer electrolyte and electrochromic device

A technology of gel polymer and electrolyte, applied in instruments, optics, nonlinear optics, etc., can solve the problems of opacity, low conductivity, no photocuring properties, etc., and achieve the effect of good conductivity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

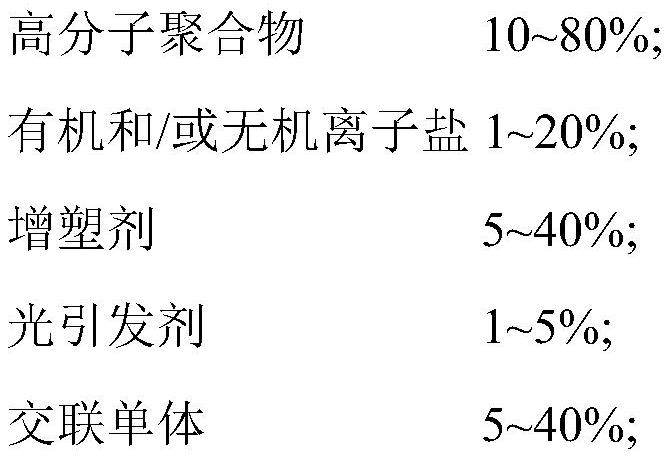

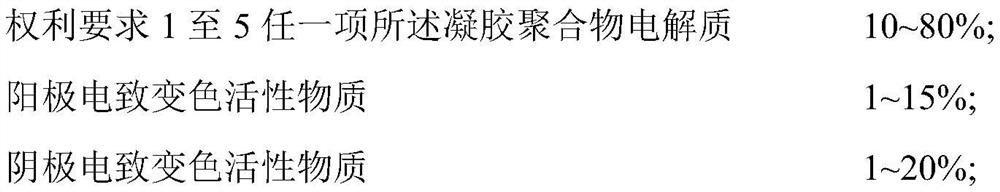

Method used

Image

Examples

Embodiment 1

[0060] S1. Preparation of high molecular polymer:

[0061] Add 50 parts of propylene carbonate as a solvent in a four-necked flask equipped with an electric stirrer, a constant pressure dropping funnel, a thermometer and a condenser tube, turn on the stirrer, and mix 20 parts of methyl methacrylate, 30 parts of hydroxyethyl methacrylate Mix the ester with 0.25 part of 2,2'-azobisisobutyronitrile and 0.1 part of dodecyl mercaptan evenly, add it into a four-necked flask under a nitrogen atmosphere, and react at 60°C for 10 hours to complete the polymerization. Cool to room temperature to obtain a polymer solution.

[0062] S2. Preparation of polymer electrolyte:

[0063] 50 parts of the above-mentioned polymer solution, LiClO 4 2 parts, 20 parts of propylene carbonate, 3 parts of 1-hydroxy-cyclohexyl-phenyl ketone, and 25 parts of hydroxyethyl acrylate were prepared into a polymer electrolyte solution.

[0064] S3. Preparation of electrochromic gel:

[0065] Dissolve 6 part...

Embodiment 2

[0071] S1. Preparation of high molecular polymer:

[0072] Add 50 parts of propylene carbonate as a solvent in a four-necked flask equipped with an electric stirrer, a constant pressure dropping funnel, a thermometer and a condenser, turn on the stirrer, and mix 20 parts of methyl methacrylate, 30 parts of polyethylene glycol methyl Mix 0.25 parts of 2,2'-azobisisobutyronitrile and 0.1 part of dodecyl mercaptan evenly, add them into a four-necked flask under a nitrogen atmosphere, and react at 60°C for 10 hours to complete Polymerize and cool to room temperature to obtain a polymer solution.

[0073] The way and consumption of S2, S3, S4 are all identical with embodiment 1.

Embodiment 3

[0075] S1. Same as Example 1.

[0076] S2. 50 parts of the above polymer solution, LiClO 4 2 parts, 20 parts of propylene carbonate, 3 parts of 1-hydroxy-cyclohexyl-phenyl ketone, and 25 parts of polyethylene glycol diacrylate were prepared into a polymer electrolyte solution.

[0077] The way and consumption of S3, S4 are all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com