Fluorine-modified PAE resin, preparation method thereof and coating composition

A fluorine-modified and resin technology, applied in the field of fluorine-modified PAE resin and its preparation method and coating composition, can solve the problems of insufficient elasticity, high rigidity of the coating, easy cracking and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The fluorine-containing PAE resin of embodiment 1 organosilicon modification

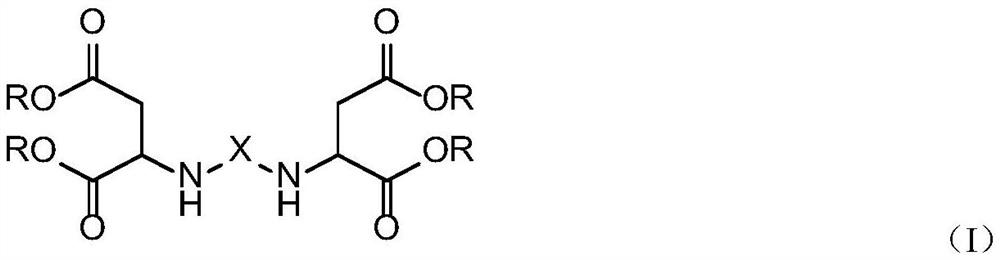

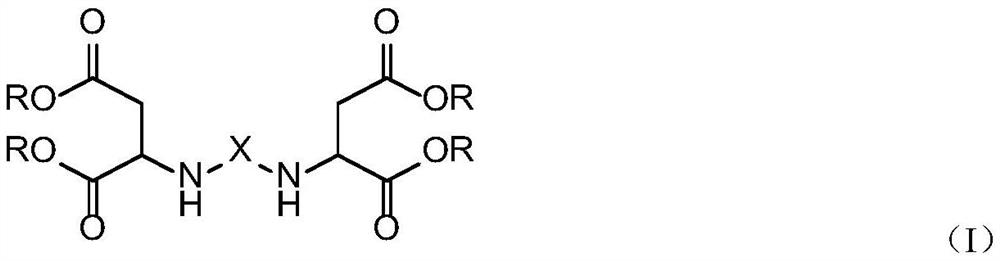

[0040] A kind of organosilicon-modified fluorine-containing PAE resin, as shown in formula (I):

[0041]

[0042] R is perfluoroethyl, and X comes from 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane (also known as "amino dicaps").

[0043] The preparation method is as follows:

[0044] (1) Add the amino double head into the flask equipped with a water separator, add 20wt% xylene and heat up to reflux until dehydration, then vacuumize 0.6MPa to separate the xylene solvent;

[0045] (2) Cool down to 40-60°C, add dropwise the mixture of perfluorodiethyl maleate and acrylonitrile under the condition of nitrogen gas, wherein the mixture of amino double head and perfluorodiethyl maleate and acrylonitrile The molar ratio of the mixture is 1:2.1, and the molar ratio of perfluorodiethyl maleate to acrylonitrile is 10:0.8. Gradually raise the temperature to 60-65° C. at the end of the dropw...

Embodiment 2

[0046] The fluorine-containing PAE resin of embodiment 2 organosilicon modification

[0047] A kind of organosilicon-modified fluorine-containing PAE resin, identical with the general formula (I) of embodiment 1, R is a perfluoropropyl group, and its difference is: X comes from the amino-terminated silicone oil of molecular weight 400 (1,3-bis( 3-Aminopropyl)-1,1,3,3-Tetramethyldisiloxane reacts with octamethylcyclotetrasiloxane D4 (an amino-terminated silicone oil polymer with an average molecular weight of 400).

[0048] The preparation method is as follows:

[0049] (1) Add amino-terminated silicone oil into a flask equipped with a water separator, add 20wt% xylene and heat up to reflux until dehydration, and then vacuumize 0.6MPa to separate the xylene solvent;

[0050] (2) Cool down to 40-60°C, add dropwise the mixture of perfluorodipropyl maleate and acrylonitrile under the condition of nitrogen gas, in which the molecular weight is 400 terminal amino silicone oil and p...

Embodiment 3

[0051] The fluorine-containing PAE resin of embodiment 3 polyether amine modification

[0052]A polyetheramine-modified fluorine-containing PAE resin, the same as the general formula (I) of Example 1, R is a perfluoroethyl group, and the difference is that X comes from polyetheramine (D400, Huntsman, USA).

[0053] The preparation method is as follows:

[0054] (1) Add D400 in the flask equipped with a water separator, add 20wt% xylene and heat up to reflux until dehydration, then vacuumize 0.6MPa to separate the xylene solvent;

[0055] (2) Lower the temperature to 40-60°C, add the mixture of perfluorodipropyl maleate and acrylonitrile dropwise under the condition of blowing nitrogen gas, wherein, the mole of D400 and the mixture of perfluorodipropyl maleate and acrylonitrile The ratio is 1:2.1, and the molar ratio of perfluorodipropyl maleate to acrylonitrile is 10:0.9. When the dropwise reaction ends, the temperature is gradually raised to 60-65° C., and then maintained a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com