Preparation process of mesophase pitch and pitch-based carbon fiber

A technology of pitch-based carbon fiber and mesophase pitch, applied in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch with selective extraction, fiber chemical characteristics, etc., can solve the problem of unrealized inferior heavy oil High value-added utilization and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Pretreatment to obtain aromatic-rich oil

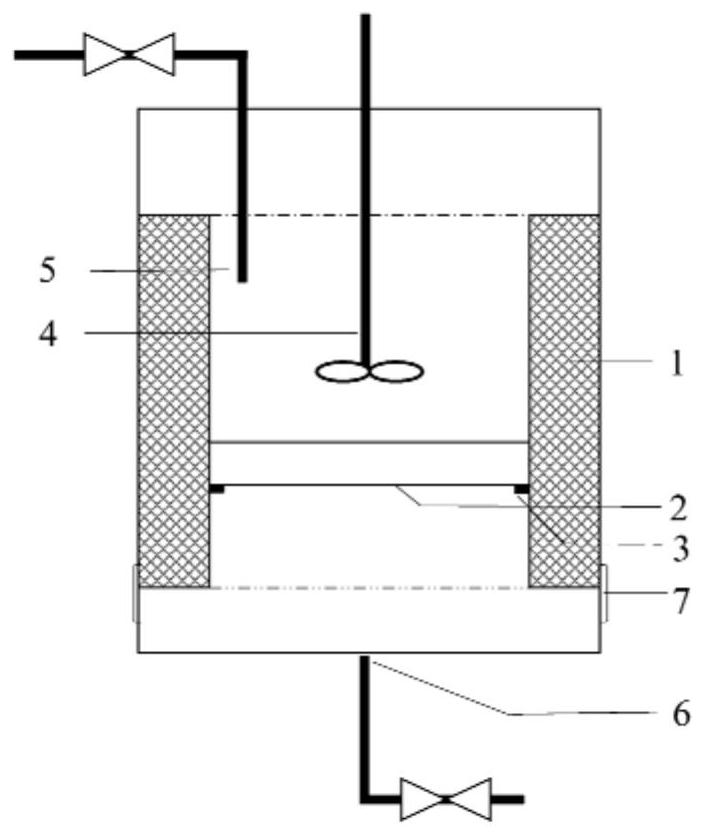

[0031] Under the condition of absolute pressure of 5KPa, 3000g of catalytic oil slurry was subjected to vacuum precision fractionation to obtain a heavy distillation section greater than 300°C, and the mixed component of the extractant furfural (mixing volume ratio 1-5) was mixed with 0.5-1m 3 The flow rate per hour is sent to the ultrasonic thermal filtration coupling extraction system, the power of the ultrasonic generator is adjusted to 600-900W, the temperature of the mixed material is 60-90°C, a ceramic membrane with a pore size of 20-200nm is used as the filter medium, and then the filtrate is Static sedimentation and solvent oil separation, take the extracted oil and introduce it into the gel permeation chromatographic column;

[0032] Add a glass wool pad at the bottom of the gel column, add polystyrene gel, and add a glass wool pad at the top, wet the gel column with 50ml of tetrahydrofuran, mix 100ml of tet...

Embodiment 2

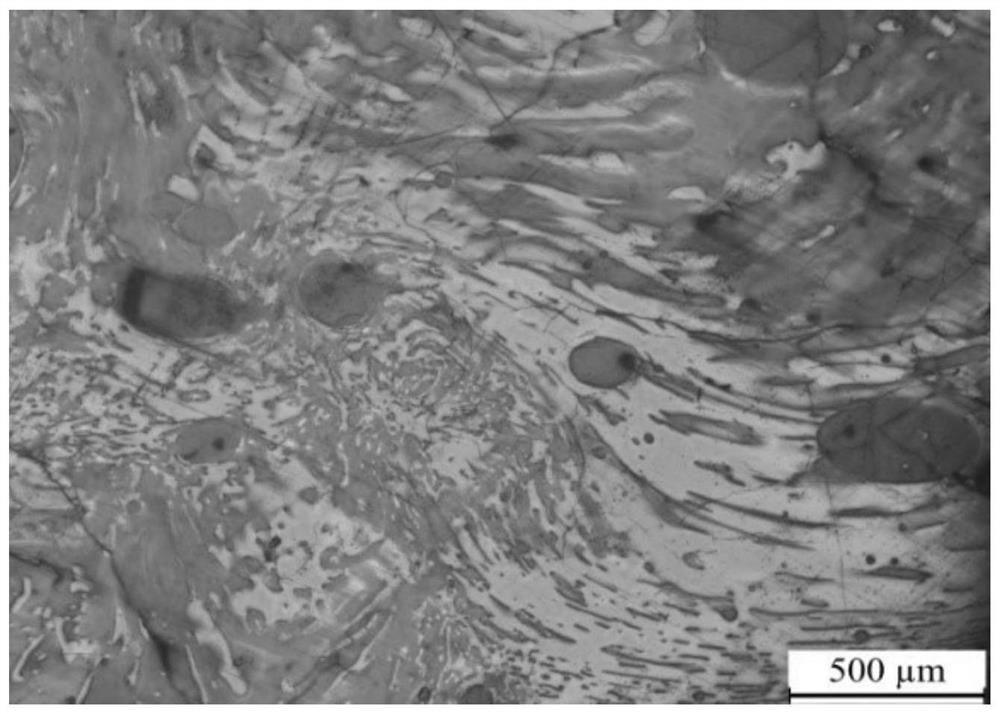

[0035] The pretreatment of vacuum distillate oil is the same as in Example 1 to obtain aromatic-rich oil. After mixing 200g of aromatic-rich oil and 20g of lignin evenly, add it to the reactor, then add 10g of tetralin, cover the lid of the kettle, and keep the reactor airtight. sex is good. Use high-purity nitrogen to replace the air in the reactor for 3 times, and finally fill the reactor with high-purity nitrogen to 4MPa; (2) Turn on the heating switch, adjust the speed to 500r / min, and control the reaction temperature to 410°C, reaction pressure to 4MPa, and reaction time After 6 hours, reduce the pressure to normal pressure, take out the reaction kettle, put it into cold water for rapid cooling, and open the reaction kettle when it is cooled to room temperature to obtain mesophase pitch. The obtained mesophase pitch has a large basin structure in which the anisotropic phase is the continuous phase, the H / C ratio is 0.60, the carbon residue value is 83, the mesophase conte...

Embodiment 3

[0037] The pretreatment of ethylene tar is the same as in Example 1 to obtain rich aromatics oil, mix 200g rich aromatics oil with 20g chitosan and add to the reaction kettle, then add 5g tetrahydroquinoline, cover the still lid, and keep the reaction kettle airtight sex is good. Use high-purity nitrogen to replace the air in the reactor for 3 times, and finally fill the reactor with high-purity nitrogen to 6MPa; (2) Turn on the heating switch, adjust the speed to 500r / min, and control the reaction temperature to 420°C, reaction pressure to 6MPa, and reaction time After 8 hours, reduce the pressure to normal pressure, take out the reaction kettle, put it into cold water for rapid cooling, and open the reaction kettle when it is cooled to room temperature to obtain mesophase pitch. The obtained mesophase pitch has a large basin structure in which the anisotropic phase is the continuous phase, the H / C ratio is 0.65, the carbon residue value is 82, the mesophase content is 90%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com