Self-cleaning hydrotalcite/fiber fabric composite material with wear resistance and self-repairing functions and preparation method thereof

A fiber fabric and composite material technology, applied in the direction of wear-resistant fibers, liquid-repellent fibers, fiber types, etc., can solve the problems of cumbersome preparation methods, rough surface structure of super-hydrophobic fabrics, easy damage, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

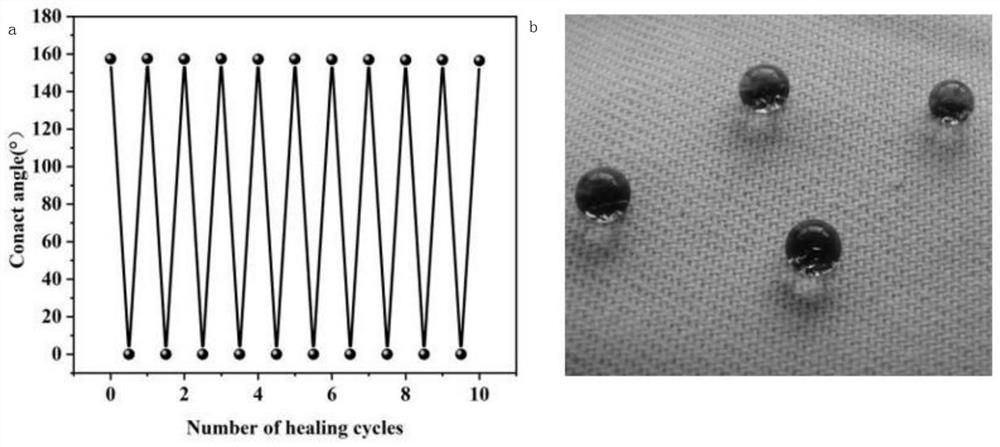

[0031] The invention discloses a self-cleaning hydrotalcite / fiber fabric composite material with wear-resistant and self-repairing functions and a preparation method thereof. The preparation method specifically includes the following contents:

[0032] (1) Wash the fabric with detergent, rinse it with deionized water and ethanol, and dry it for later use.

[0033] (2) At room temperature, a certain amount of divalent metal salts and trivalent metal salts are added to an appropriate amount of deionized water respectively, the divalent metal salts are aluminum nitrate, and the trivalent metal salts are aluminum nitrate, magnesium chloride, nitric acid Magnesium, cobalt nitrate or nickel nitrate. Stir evenly under the action of the magnetic rotor, the stirring rate is 100-500r / min, and the stirring time is 5-20min. After stirring, a uniform solution A is formed; Stir for 10-30 minutes, after adding urea, the acidity and alkalinity of the solution can be controlled, and finally t...

Embodiment 1

[0039]

[0040] The fabrics were washed with detergent, rinsed in deionized water and ethanol, and dried before use.

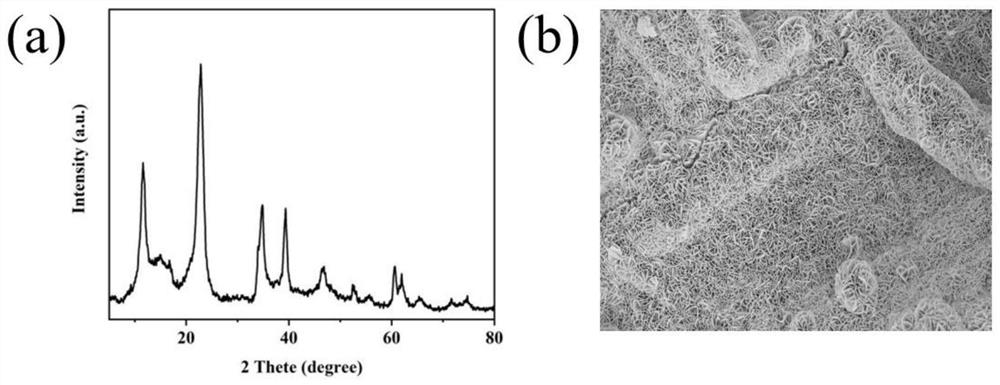

[0041] At room temperature, add 0.1 mol / L nickel nitrate and 0.05 mol / L aluminum nitrate to appropriate amount of deionized water respectively, under the action of a magnetic rotor at 200r / min, stir for 10 minutes and then stir evenly to form a homogeneous solution A; Add 0.4 mol / L ammonium fluoride and 0.3 mol / L urea, stir respectively for 20 min to obtain the precursor solution B of hydrotalcite.

[0042] Put the prepared hydrotalcite precursor solution B into the hydrothermal reaction kettle, add the cleaned fabric and soak for 20 minutes, place it in an oven, and react at 100°C for 10 hours. After the hydrothermal reaction, the samples were taken out, rinsed with deionized water, placed in an oven and dried at 50°C for 12 hours before use.

[0043] Soak the fabric with hydrotalcite in the ethanol solution of 0.08mol / L stearic acid for 30 minutes to car...

Embodiment 2

[0045]

[0046] The fabrics were washed with detergent, rinsed in deionized water and ethanol, and dried before use.

[0047] At room temperature, add 0.08 mol / L nickel nitrate and 0.1 mol / L aluminum nitrate to appropriate amount of deionized water respectively, under the action of a magnetic rotor at 300 r / min, stir for 10 min and then stir evenly to form a homogeneous solution A; then Add 0.3 mol / L ammonium fluoride and 0.2 mol / L urea, stir respectively for 30 min to obtain the precursor solution B of hydrotalcite.

[0048] Put the prepared hydrotalcite precursor solution B into a hydrothermal reaction kettle, add the cleaned fabric and soak for 10 minutes, place it in an oven, and react at 120°C for 15 hours. After the hydrothermal reaction, the samples were taken out, rinsed with deionized water, placed in an oven and dried at 100°C for 2 hours before use.

[0049] Soak the fabric with hydrotalcite in the ethanol solution of 0.06mol / L stearic acid for 20 minutes for ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com