Method for manufacturing MoO3-Li secondary battery

A battery and secondary ion technology, applied in electrolyte battery manufacturing, electrode manufacturing, battery electrodes, etc., can solve problems such as difficulty in becoming commercial Mo-Li ion batteries, battery performance degradation, and inability to provide lithium sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

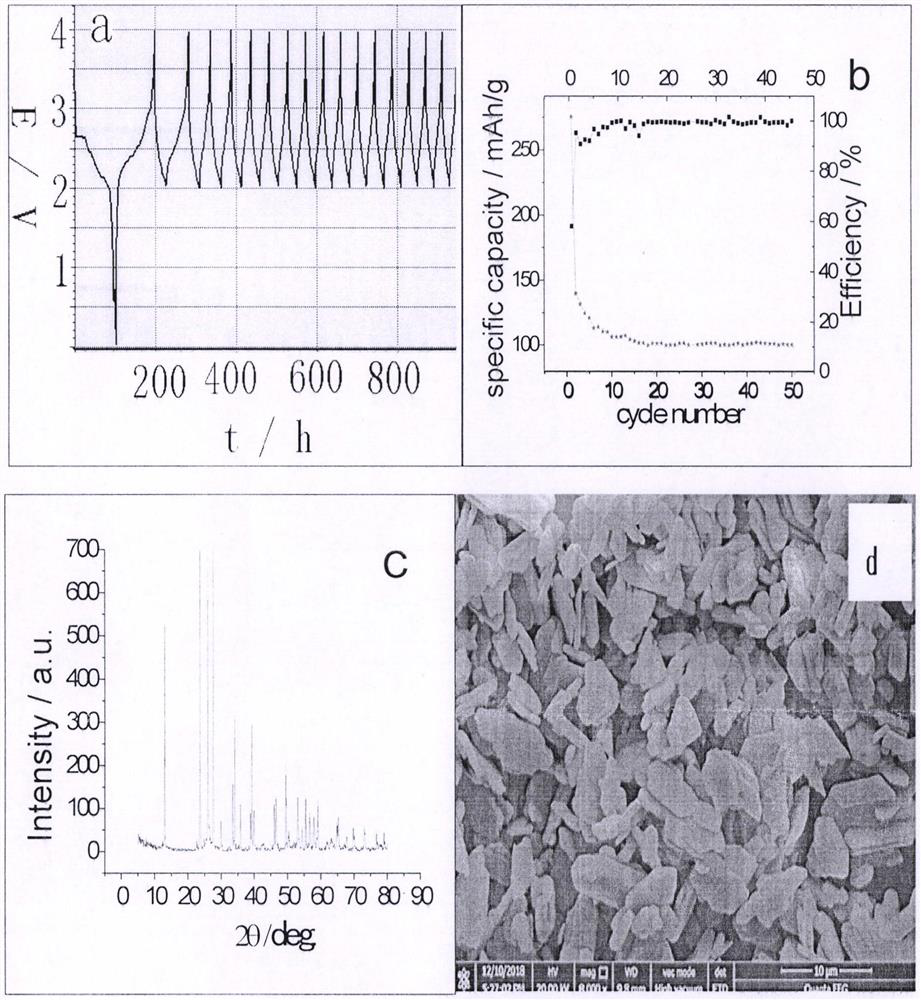

[0019] 1. Molybdenum oxide battery: 2032 stainless steel button battery shell is used, 0.2g of commercially available molybdenum oxide is used as the positive electrode material, and commercially available natural graphite is used as the negative electrode material. The electroactive material: PVDF adhesive: carbon black is 80:10:20 Preparation, 1M lithium hexafluorophosphate is the electrolyte (solvent is 1:1:1 methyl carbonate, ethylene carbonate, dimethyl carbonate), aluminum foil is the positive electrode current collector, copper foil is the negative electrode current collector, and the 2400 celgard diaphragm is the battery diaphragm. A lithium foil with a thickness of 0.2 mm, a hole diameter of 1.2 mm, and a hole distance of 1.2 mm is inserted between the battery separator and the negative electrode to assemble the battery. After the battery is sealed, at 0.1-1mA / cm 2 The current is discharged to 0 volts, and then charged to 4V with a current of 0.1-1mA; after the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com