A method for clean utilization of siderite-enhanced iron-based cyanide tailings

A technology for cyaniding tailings and siderite, applied in iron oxide/iron hydroxide, iron oxide, process efficiency improvement, etc., can solve the problems of high processing cost, land occupation, environmental pollution, etc., and reduce hazardous waste Effects on output, reduction in use, and increase in economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

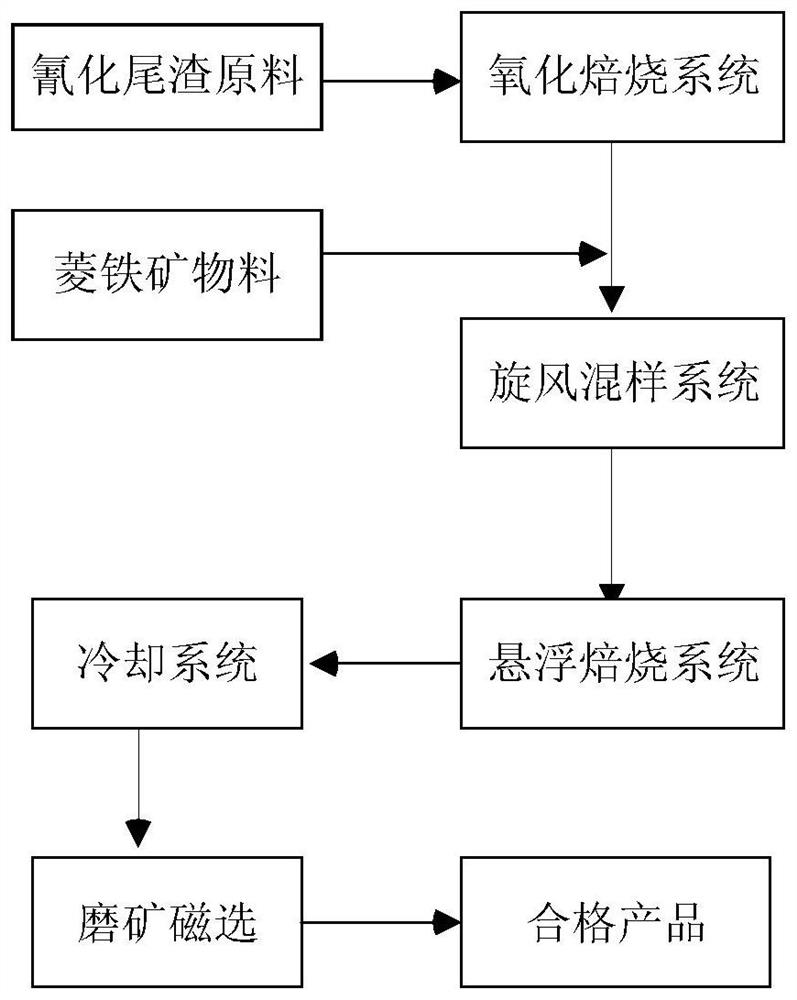

[0089] The clean utilization method of siderite enhanced iron-based cyanide tailings, the overall process flow chart is as follows figure 1 Shown, this example feeds the tailings that adopts whole mud cyanidation leaching gained tailings of a gold mine in Shanxi Province, wherein TFe content is 25.8%, (iron-containing minerals in the cyanide tailings are mainly limonite and hematite) The theoretical distribution rate of iron in limonite is 80%, and the gangue minerals are mainly mica, dolomite, calcite, and quartz) and the content of cyanide is 450mg / l. The required siderite is taken from the nearby gold mine. Concentrator (iron-containing minerals in siderite mainly exist in the form of siderite and hematite, and the distribution rates of iron in siderite and hematite are 91.20% and 7.91% respectively)

[0090] Step 1, material preparation: select the cyanidation tailings with a TFe content of 25% for pressure filtration dehydration to obtain tailings with a TFe content of 30...

Embodiment 2

[0105] The ore feeding of this example is the tailings obtained by the whole mud cyanidation leaching of a gold mine in a certain place in Yunnan Province, wherein the TFe content is 28%, and the cyanide content is 310mg / l, (iron-containing minerals in the cyanide tailings are mainly limonite) form, the theoretical distribution rate of iron in limonite is 95%, and the gangue minerals are mainly mica, dolomite, quartz) The required siderite is taken from the nearby ore processing plant (iron-containing minerals in siderite It mainly exists in the form of siderite and hematite, and the distribution rates of iron in siderite and hematite are 85.70% and 13.42% respectively)

[0106] Step 1, material preparation: select the cyanidation tailings with TFe content 28% to carry out pressure filtration dehydration, obtain TFe content 32%, water content 10% tailings, tailings after treatment -0.043mm particle size mass content more than 85% The obtained siderite ore is crushed and ground...

Embodiment 3

[0124] In this example, the ore feed is the tailings obtained by cyanidation leaching of a gold mine in a certain place in Henan Province, wherein the TFe content is 23.54%, (the iron-containing minerals in the cyanide tailings mainly exist in the form of limonite and goethite, The gangue minerals are mainly mica, dolomite, calcite, and quartz) with a cyanide content of 450mg / l, and the required siderite is taken from a beneficiation plant near the gold mine (the iron-containing minerals in siderite are mainly siderite and red It exists in the form of iron ore, and the distribution rates of iron in siderite and hematite are 89.17% and 7.91%, respectively)

[0125] Step 1, material preparation: select cyanidation tailings with a TFe content of 23.54% for pressure filtration dehydration to obtain tailings with a TFe content of 28% and a water content of 8%. After the tailings are treated, the mass content of -0.043mm particle size is more than 95%; The obtained siderite ore is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com