Device and method for deeply concentrating high-salt-content wastewater through low-temperature phase change crystallization and application

A low-temperature phase change, high-salt technology, which can be used in energy and wastewater treatment, general water supply conservation, and chilled water/sewage treatment. The effect of reduced processing cost, cost saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

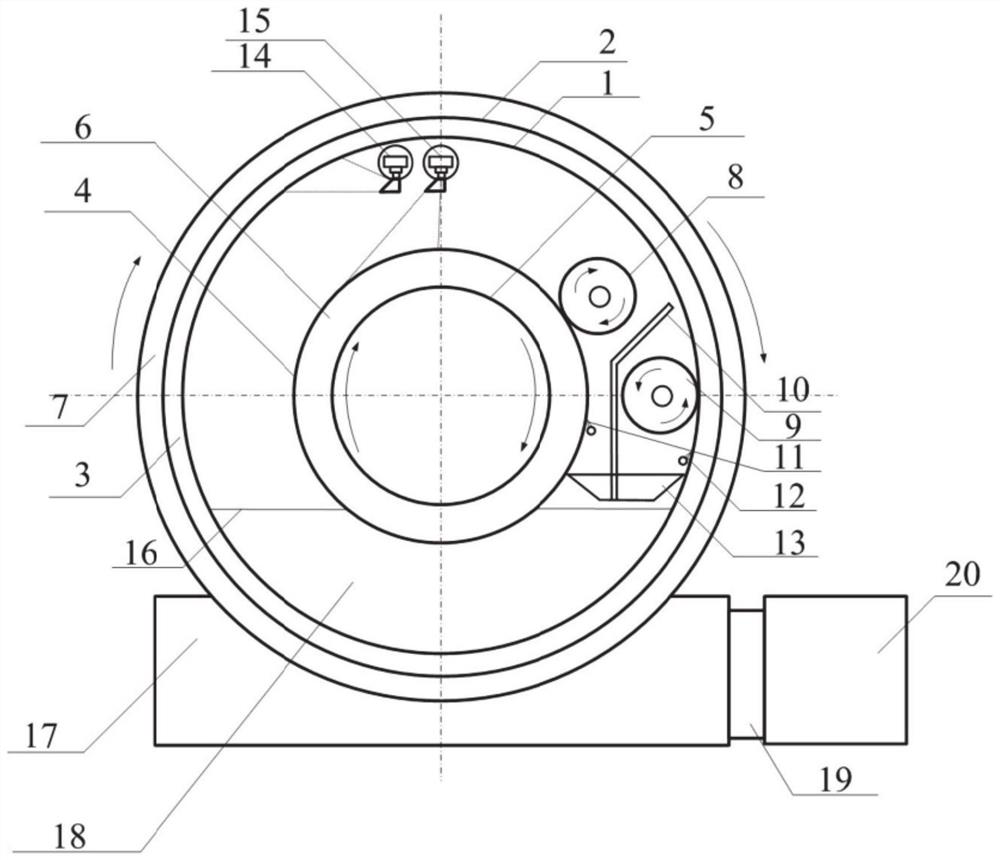

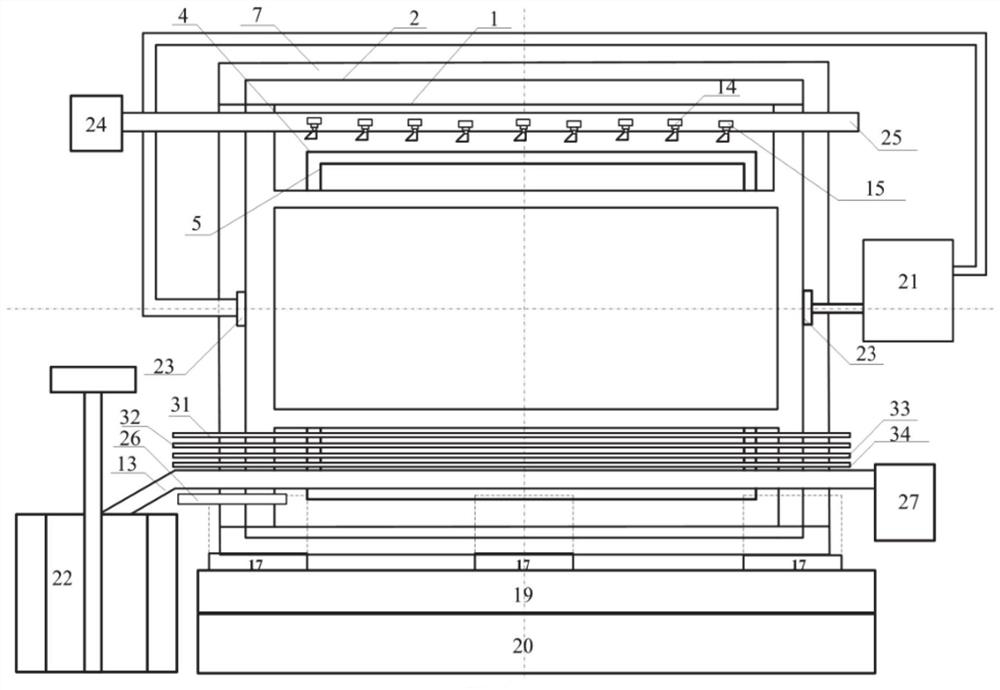

[0056] Such as Figure 1-Figure 4 As shown, the device includes an inner cooling drum 1, an outer cooling drum 5, a water mist nozzle 14, an inner cold wall pressure roller 9, an outer cold wall pressure roller 8, an inner cold wall ice scraper 12, and an outer cold wall ice scraper 11. Ice body transmission plate 13, rotary transmission device 17, speed changer 19, electric motor 20, refrigeration unit 21, ice-water separator 22. Both the inner cooling drum 1 and the outer cooling drum 5 are in the shape of a horizontal cylinder, the outer cooling drum 5 is located inside the cavity of the inner cooling drum 1, and the diameter of the outer cooling drum 5 is smaller than the The diameter of the internal cooling drum 1 is described above, the motor 20 is connected to the rotary transmission device 17 through the transmission 19, and the rotary transmission device 17 drives the internal cooling drum 1 and the external cooling drum 5 to rotate around the central axis of the cyli...

Embodiment 2

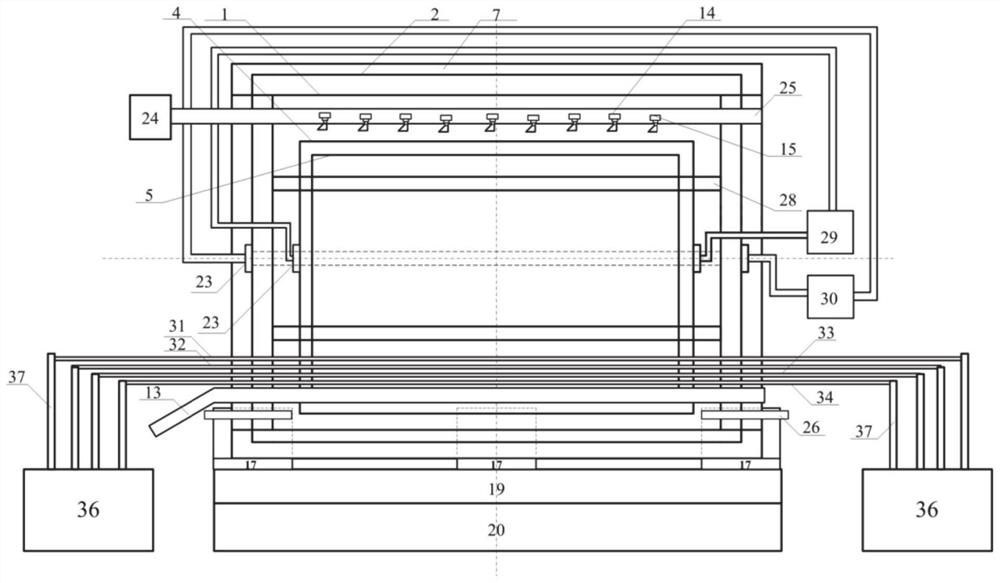

[0086] Such as Figure 13As shown, the device includes an inner cooling drum 1, an outer cooling drum 5, a water mist nozzle 14, an inner cold wall pressure roller 9, an outer cold wall pressure roller 8, an inner cold wall ice scraper 12, and an outer cold wall ice scraper 11. Ice body transfer plate 13, rotary transmission device 17, speed changer 19, motor 20, refrigeration unit 21, ice-water separator 22, electric adsorption tube 35 (36, 37, 38). Both the inner cooling drum 1 and the outer cooling drum 5 are in the shape of a horizontal cylinder, the outer cooling drum 5 is located inside the cavity of the inner cooling drum 1, and the diameter of the outer cooling drum 5 is smaller than the The diameter of the internal cooling drum 1 is described above, the motor 20 is connected to the rotary transmission device 17 through the transmission 19, and the rotary transmission device 17 drives the internal cooling drum 1 and the external cooling drum 5 to rotate around the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com