Coupling agent modified nano hydrated calcium silicate crystal nucleus early strength agent and preparation method thereof

A technology of calcium silicate hydrate and coupling agent, which is applied in the field of concrete early strength agent, can solve the problems of large CSH crystal nucleus particle size, easily broken charge balance, and reduced effective surface area, etc., and achieves high electrostatic repulsion and space potential. resistance, is conducive to performance, and optimizes the effect of particle gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

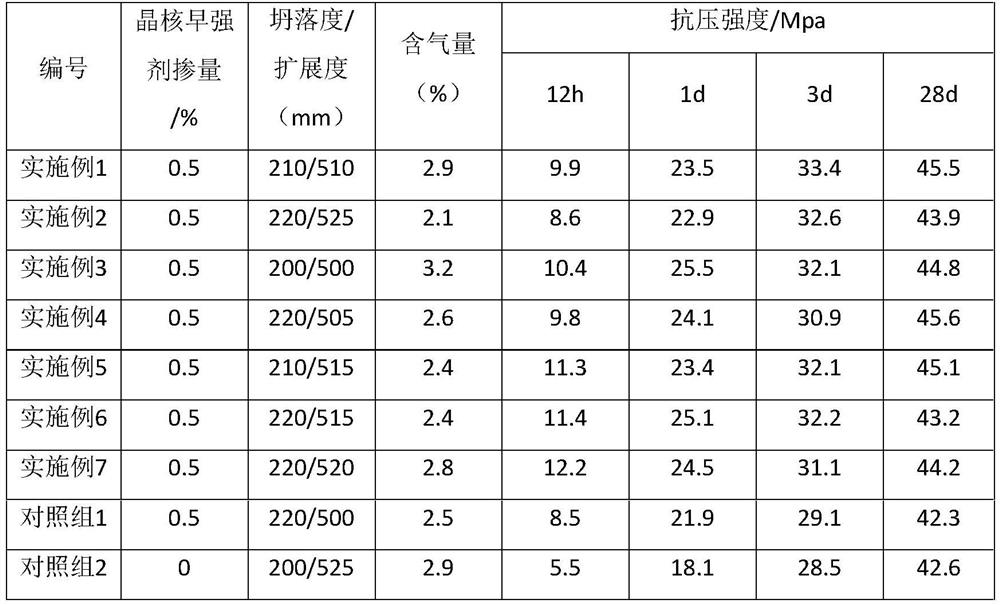

Examples

preparation example Construction

[0020] A preparation method of the coupling agent-modified nano-calcium silicate hydrate crystal nucleus accelerator, comprising the following steps: Step S01: adding a dispersant and a coupling agent to the container, and then adding ionized water to the prepared Half of the quality of the early strength agent, and the dispersant, coupling agent, and ionized water are placed in a water bath and stirred to prepare the base material; step S02: adding the soluble calcium source aqueous solution dropwise to the base material prepared in step S01 at the same time and soluble silicon source aqueous solution, after the dropwise addition, keep warm; step S03: add ionic water to the bottom material to the quality of the early strength agent to be prepared, and obtain the coupling agent modified nano-calcium silicate hydrate crystal nucleus early strength agent .

[0021] In step S01, the stirring rate is 300-1600 rpm.

[0022] In step S01, the temperature of the water bath is 25-85°C...

Embodiment 1

[0027] The preparation steps are as follows:

[0028] (1) Place 25 parts of polycarboxylic acid dispersant and 2.5 parts of 3-aminopropyltrimethoxysilane coupling agent in a 3-necked flask with a stirring device, then make up 500 parts of deionized water, and place the three-necked flask The bottle is equipped with a stirring device, and placed in a water bath, the temperature of the water bath is controlled at 35°C, and the stirring rate is controlled at 800rpm;

[0029] (2) 20 parts of calcium nitrate tetrahydrate are mixed with 100 parts of aqueous solution of 20% mass concentration, and 30 parts of sodium metasilicate pentahydrate are mixed with 150 parts of aqueous solution of 20% mass concentration;

[0030](3) the calcium nitrate tetrahydrate aqueous solution of step (2) and the sodium metasilicate pentahydrate aqueous solution are added dropwise to the base material of step (1) simultaneously, and the time for adding is 5h, and the insulation is 1h, and the temperature...

Embodiment 2

[0033] The preparation steps are as follows:

[0034] (1) Put 25 parts of polycarboxylic acid dispersant and 2.5 parts of 3-glycidyl etheroxypropyl trimethoxysilane coupling agent in a 3-neck flask with a stirring device, and then add deionized water to 500 parts , put the three-necked flask with a stirring device, and place it in a water bath, control the temperature of the water bath at 45°C, and control the stirring rate at 800rpm;

[0035] (2) 20 parts of calcium acetate are mixed with 100 parts of aqueous solution of 20% mass concentration, and 30 parts of sodium metasilicate pentahydrate are mixed with 150 parts of aqueous solution of 20% mass concentration;

[0036] (3) The calcium acetate aqueous solution of step (2) and the sodium metasilicate pentahydrate aqueous solution are added dropwise to the base material of step (1) simultaneously, and the dropwise addition time is 4h, and the insulation is 2h, and the dropwise addition temperature and the insulation temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com