A kind of preparation method and application of nano silicon dioxide-fluorine-containing polyacrylate composite matting agent

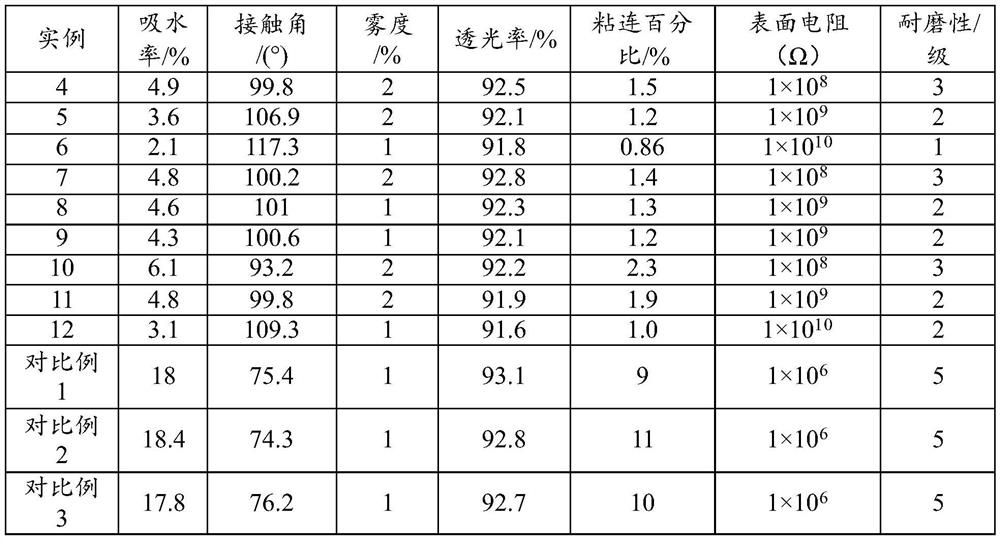

A technology of nano-silica and polyacrylate, applied in biocide-containing paints, conductive coatings, coatings, etc., can solve the problems of anti-adhesive performance to be improved, achieve high surface resistance, improve anti-adhesive performance, and high The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

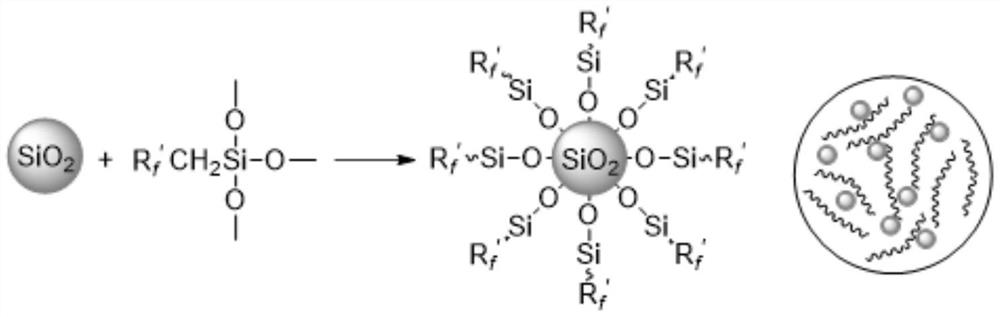

[0025] The present invention provides a kind of preparation method of nano silicon dioxide-fluorine-containing polyacrylate composite matting agent, comprising the following steps:

[0026] nano-SiO 2 , anhydrous ethanol, water, ammonia water and silane coupling agent react to obtain modified nano-SiO 2 ;

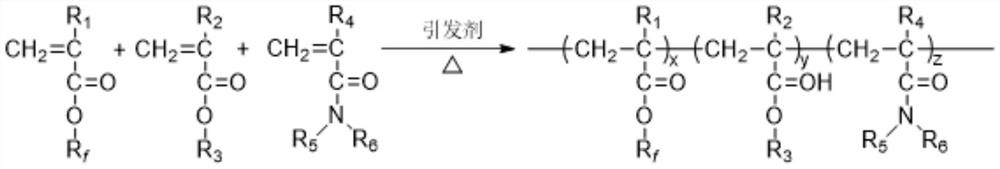

[0027] Mix part of emulsifier aqueous solution, part of fluorine-containing acrylate, part of acrylate and part of acrylamide, and pre-emulsify to obtain a pre-emulsion;

[0028] The remaining part of emulsifier aqueous solution, the remaining part of fluorine-containing acrylate, the remaining part of acrylate, the remaining part of acrylamide and modified nano-SiO 2 Mixing, adding an initiator, reacting, adding the pre-emulsion dropwise to continue the reaction, adjusting the pH value to 7-8, and obtaining a nano-silica-fluorine-containing polyacrylate composite matting agent.

[0029] The present invention adopts fluorine-containing ethyl acrylate, acrylate and acryla...

Embodiment 1

[0057] Example 1 Modified nano silicon dioxide n-SiO 2 - Preparation of F1

[0058] In a 250ml flask, add 8.0g dry nano-SiO 2 Particles, 160ml of absolute ethanol, 10mL of deionized water, 4g of 25% ammonia water and 3g of fluorine-containing alkoxysilane (3,3,3-trifluoropropyl)trimethoxysilane. Ultrasonic dispersion was performed for 1 hour, and high-speed stirring was performed at room temperature for 24 hours. Filter the precipitate, wash with 10 mL of absolute ethanol three times, remove unreacted alkoxysilane, etc., and dry in vacuum to obtain white powder n-SiO 2 -F1.

Embodiment 2

[0059] Example 2: Modified nano silicon dioxide n-SiO 2 - Preparation of F2

[0060] In a 250ml flask, add 8.0g dry nano-SiO 2 Particles, 150ml of absolute ethanol, 10mL of deionized water, 4g of 25% ammonia water and 3g of fluorine-containing alkoxysilane trifluoropropyltriethoxysilane. Ultrasonic dispersion was performed for 1 hour, and high-speed stirring was performed at room temperature for 24 hours. Filter the precipitate, wash with 10 mL of absolute ethanol three times, remove unreacted alkoxysilane, etc., and dry in vacuum to obtain white powder n-SiO 2 -F2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com