A kind of antibacterial and mildew proof polyurethane paint film based on n-alkyl glycol amine and preparation method thereof

An alkyl glycol amine, antibacterial and antifungal technology, which is applied in polyurea/polyurethane coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve problems such as environmental pollution and antibacterial performance reduction, and achieve reduction Infection, long-lasting effect, and the effect of reducing secondary infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

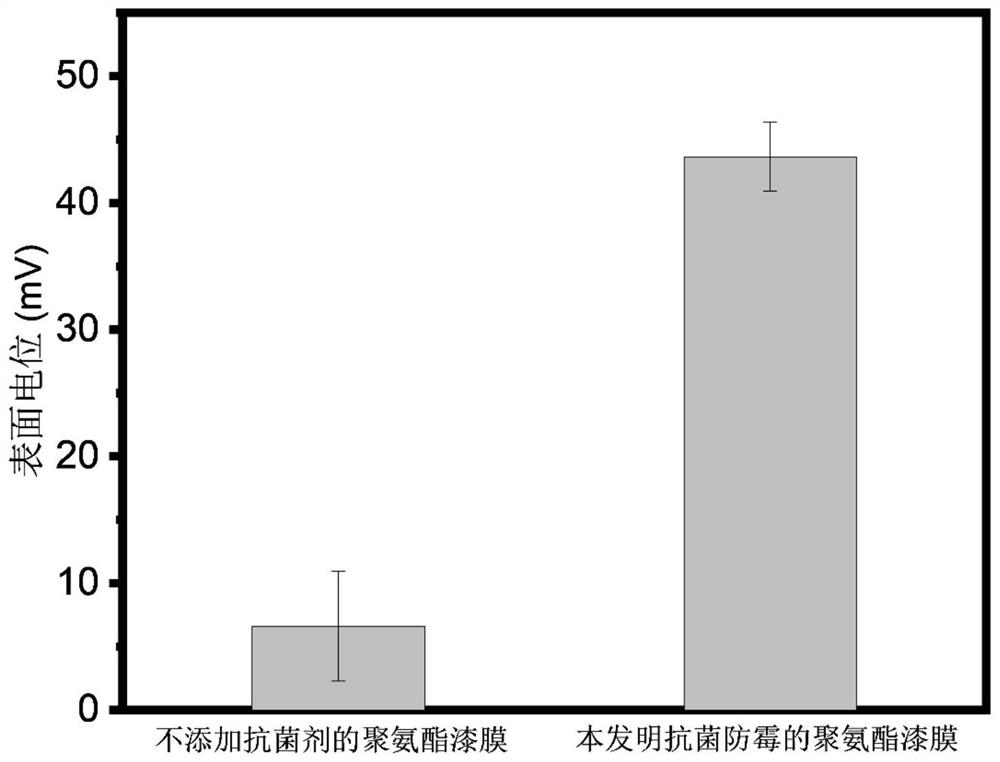

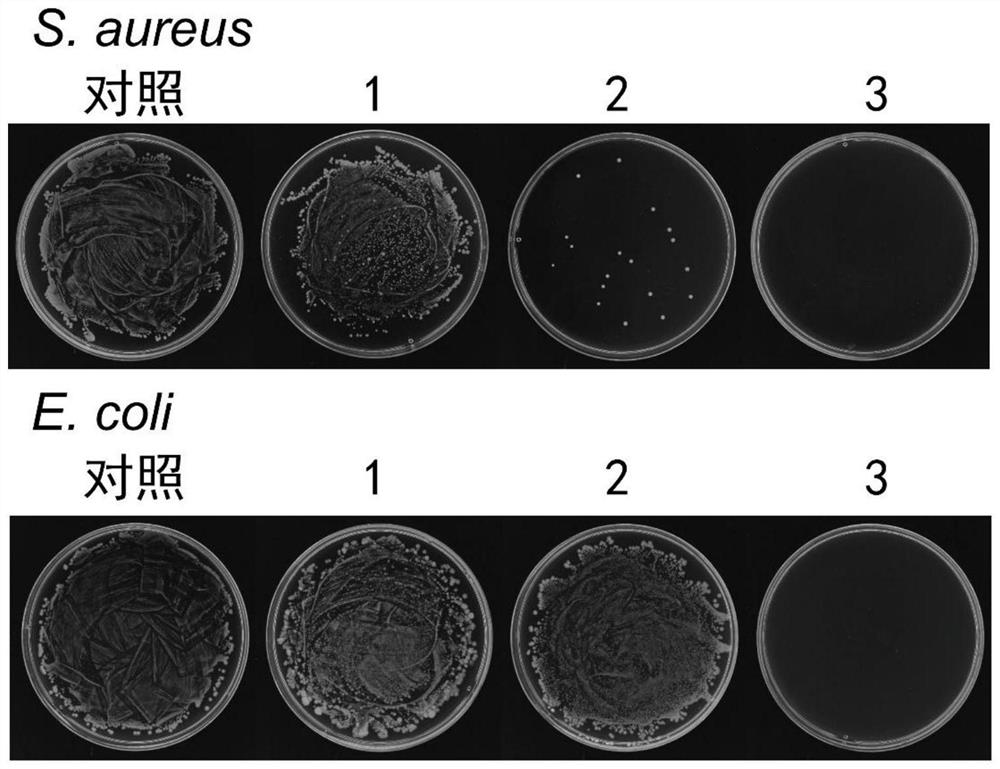

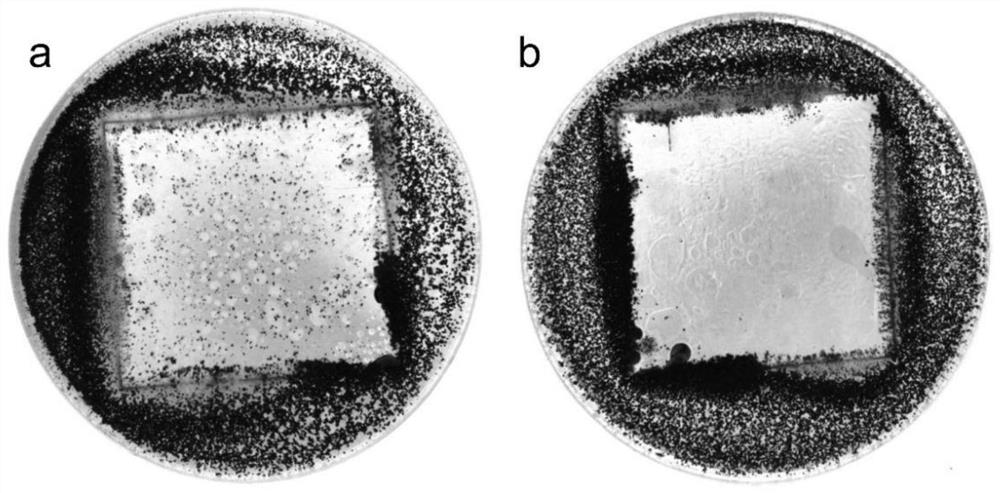

[0027] Dissolve 5.95g of N-methyldiethanolamine and 10.3g of bromohexane in 15g of ethanol, stir to form a homogeneous solution, heat the above solution to 70°C, condense and reflux for 24 hours; precipitate with ethyl acetate, and dry in vacuo to obtain white A solid powder of hexyl bromide quaternized N-methyldiethanolamine (QMDEA-C6).

[0028] Take 7.37g of quaternized N-methyldiethanolamine, 26.32g of 2-ethyl-1,3-hexanediol, 15.57g of butyl acetate, and 0.05g of dibutyltin dilaurate, mix them, and stir them evenly with ultrasonic; the resulting solution Nitrogen was introduced and heated to 60°C; 43.73g of 1,6-hexamethylene diisocyanate and 15.57g of butyl acetate were added to the above solution, heated to 70°C, and reacted for 6 hours to obtain an antibacterial polyurethane coating. Paint it on the surface of the metal base material with a brush, and dry it to obtain an antibacterial and antifungal polyurethane paint film.

[0029] The raw material formula is 284 parts ...

Embodiment 2

[0032] Dissolve 5.25g of N-methyldiethanolamine and 8.11g of bromooctane in 15g of ethanol, stir to form a homogeneous solution, heat the above solution to 70°C, condense and reflux for 24 hours; precipitate with ethyl acetate, and dry in vacuo to obtain white A solid powder of bromooctyl quaternized N-methyldiethanolamine (QMDEA-C8).

[0033] Take 7.37g of quaternized N-methyldiethanolamine, 26.32g of 2-ethyl-1,3-hexanediol, 15.57g of butyl acetate, and 0.05g of dibutyltin dilaurate, mix them, and stir them evenly with ultrasonic; the resulting solution Nitrogen was introduced and heated to 60°C; 43.73g of 1,6-hexamethylene diisocyanate and 15.57g of butyl acetate were added to the above solution, heated to 70°C, and reacted for 6 hours to obtain an antibacterial polyurethane coating. Paint it on the surface of the metal base material with a brush, and dry it to obtain an antibacterial and antifungal polyurethane paint film.

[0034] The raw material formula is 284 parts of ...

Embodiment 3

[0037] Dissolve 8.88g of N-methyldiethanolamine and 15.56g of bromododecane in 15g of ethanol, stir to form a homogeneous solution, heat the above solution to 70°C, condense and reflux for 24 hours; precipitate with ethyl acetate, and dry in vacuo A white solid powder bromododecyl quaternized N-methyldiethanolamine (QMDEA-C12) was obtained.

[0038] Take 7.37g of quaternized N-methyldiethanolamine, 26.32g of 2-ethyl-1,3-hexanediol, 15.57g of butyl acetate, and 0.05g of dibutyltin dilaurate, mix them, and stir them evenly with ultrasonic; the resulting solution Nitrogen was introduced and heated to 60°C; 43.73g of 1,6-hexamethylene diisocyanate and 15.57g of butyl acetate were added to the above solution, heated to 70°C, and reacted for 6 hours to obtain an antibacterial polyurethane coating. Paint it on the surface of the metal base material with a brush, and dry it to obtain an antibacterial and antifungal polyurethane paint film.

[0039] The raw material formula is 284 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com