Molybdenum ore leaching residue comprehensive utilization process

A technology for leaching slag and molybdenum ore, which is applied to the improvement of process efficiency, silicate, ferric sulfate, etc., and can solve the problems of many impurity removal steps, multiple types of impurity removers, and environmental threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

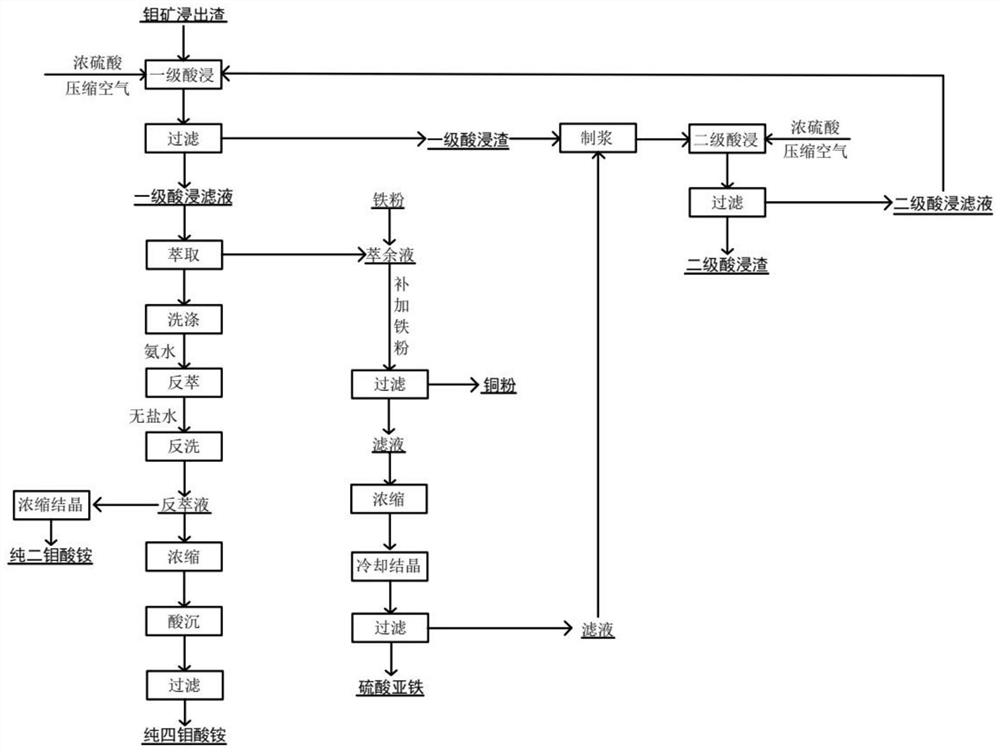

Image

Examples

Embodiment 1

[0030] In this embodiment, the main metal components of molybdenum ore leaching slag are: Mo: 1.2%, iron content 18.1%, copper content 4.5%, and Ca 2.5%.

[0031] refer to figure 1 , the main process is as follows:

[0032] 1. Pickling

[0033] 1. Primary acid leaching: mix the molybdenum ore leaching slag with the secondary acid leaching filtrate according to the solid-liquid ratio of 1:8, add concentrated sulfuric acid (Wt98%) according to the hydrochloric acid concentration of 100g / l, heat to 80°C, and use compressed air The pressure is 0.15MPa and passed into the leaching tank, after 2.5 hours of reaction, it is filtered, the filtrate enters the extraction step, and the first-stage acid leaching residue enters the second-stage acid leaching.

[0034] 2. Secondary acid leaching: the primary acid leaching residue and ferrous sulfate filter mother liquor are made into pulp according to the solid-to-liquid ratio of 1:15, and concentrated sulfuric acid (Wt98%) is added accord...

Embodiment 2

[0041] In this embodiment, the main metal components of molybdenum ore leaching slag are: Mo: 0.8%, iron content 23.4%, copper content 3.7%, and Ca 1.5%.

[0042] refer to figure 1 , the main process is as follows:

[0043] 1. Pickling

[0044] 1. Primary acid leaching: mix molybdenum ore leaching slag with secondary acid leaching filtrate according to the solid-to-liquid ratio of 1:20, add concentrated sulfuric acid (Wt98%) according to the hydrochloric acid concentration of 120g / l, heat to 90°C, and use compressed air The pressure of 0.2MPa is passed into the leaching tank, and it is filtered after reacting for 2 hours. The primary acid leaching filtrate enters the extraction step, and the primary acid leaching residue enters the secondary acid leaching.

[0045] 2. Secondary acid leaching: the primary acid leaching residue and ferrous sulfate filtered mother liquor are made into pulp according to the solid-to-liquid ratio of 1:20, and concentrated sulfuric acid (Wt98%) is...

Embodiment 3

[0052] In this embodiment, the main metal components of molybdenum ore leaching slag are: Mo: 8%, iron content 25%, copper content 0.5%, and Ca 5%.

[0053] refer to figure 1 , the main process is as follows:

[0054] 1. Pickling

[0055] 1. Primary acid leaching: mix molybdenum ore leaching slag with industrial water or secondary acid leaching filtrate according to the solid-to-liquid ratio of 1:10, add concentrated sulfuric acid (Wt98%) according to the hydrochloric acid concentration of 80g / l, heat to 90°C, Use compressed air with a pressure of 0.3 MPa to pass into the leaching tank, react for 5 hours and then filter, the filtrate enters the extraction step, and the first-stage acid leaching residue enters the second-stage acid leaching.

[0056] 2. Secondary acid leaching: the primary acid leaching residue and ferrous sulfate filtered mother liquor are made into pulp according to the solid-to-liquid ratio of 1:8, and concentrated sulfuric acid (Wt98%) is added according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com