Silk fiber deodorant as well as preparation method and application thereof

A technology of silk fiber and deodorant, which is applied in the field of textile printing and dyeing, can solve the problems of anti-wrinkle, poor anti-ultraviolet and antibacterial performance, and reduce the wearability and use value of silk textiles, achieve good deodorization effect, reduce the odor of bacterial metabolites, Effects of mild application conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

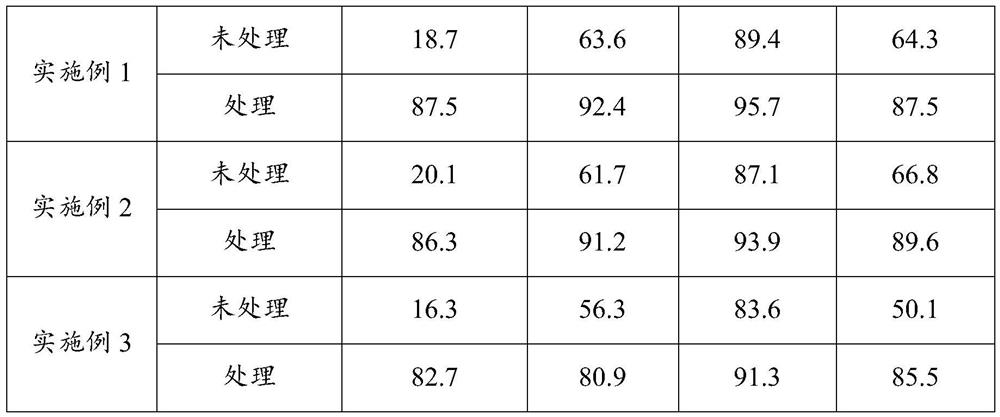

Embodiment 1

[0031] The present embodiment provides the preparation of deodorant and the method for its application on silk crepe chine, comprising the following steps:

[0032] (1) Preparation of deodorant

[0033] Dissolve polyethyleneimine with a molecular mass of 10000 in water, and stir evenly to obtain polyethyleneimine aqueous solution. Dissolve the sericin powder in water, slowly add the sericin aqueous solution into the polyethyleneimine aqueous solution under continuous stirring, and stir at room temperature for 2 hours at high speed to obtain a liquid deodorant. Wherein, the consumption of polyethyleneimine and sericin is 20g / L.

[0034] (2) Application method of deodorant

[0035] Take the liquid deodorant obtained in step (1), dilute it with water, add fatty alcohol polyoxyethylene ether surfactant (Pingping plus O), add 40% glyoxal solution, adjust the pH value to 6, and obtain the treatment solution. Among them, the dosages of liquid deodorant, 40% glyoxal and flat plus O...

Embodiment 2

[0037] The present embodiment provides the preparation of deodorant and the method for its application on silk spinning plain weave, comprising the following steps:

[0038] (1) Preparation of deodorant

[0039] Dissolve polyethyleneimine with a molecular mass of 2500 in water and stir evenly to obtain polyethyleneimine aqueous solution; dissolve sericin powder in water, and slowly add sericin aqueous solution into polyethyleneimine aqueous solution under continuous stirring , stirring at high speed at room temperature for 2 hours to obtain a liquid deodorant; wherein, the amounts of polyethyleneimine and sericin were 30 g / L and 20 g / L, respectively.

[0040] (2) Application method of deodorant

[0041] Take the liquid deodorant obtained in step (1), dilute it with water, add fatty alcohol polyoxyethylene ether surfactant (Pingping plus O), add 40% glyoxal solution, adjust the pH value to 5, and obtain the treatment solution; , The dosages of liquid deodorant, 40% glyoxal an...

Embodiment 3

[0043] The present embodiment provides a kind of deodorant and the method for its application on silk / cotton interwoven cloth, comprising the following steps:

[0044] (1) Preparation of deodorant

[0045] Dissolve polyethyleneimine with a molecular weight of 4500 in water and stir evenly to obtain polyethyleneimine aqueous solution; dissolve sericin powder in water, and slowly add sericin aqueous solution into polyethyleneimine aqueous solution under constant stirring , stirring at high speed at room temperature for 2 hours to obtain a liquid deodorant; wherein, the amounts of polyethyleneimine and sericin were 25g / L and 30g / L, respectively.

[0046] (2) Application method of deodorant

[0047]Take the liquid deodorant obtained in step (1), dilute it with water, add fatty alcohol polyoxyethylene ether surfactant (Pingping plus O), add 40% glyoxal solution, adjust the pH value to 6, and obtain the treatment solution; wherein , The dosages of liquid deodorant, 40% glyoxal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com