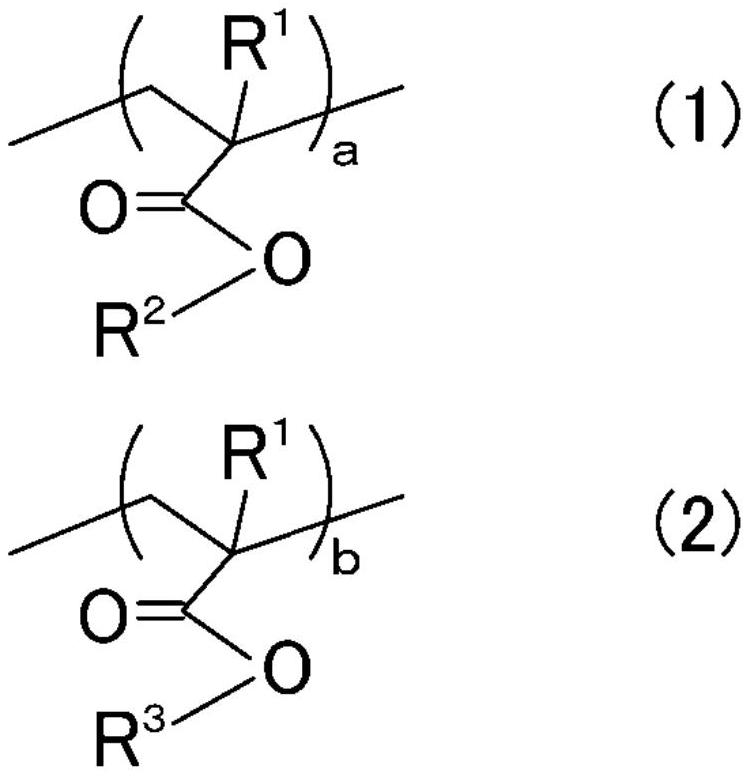

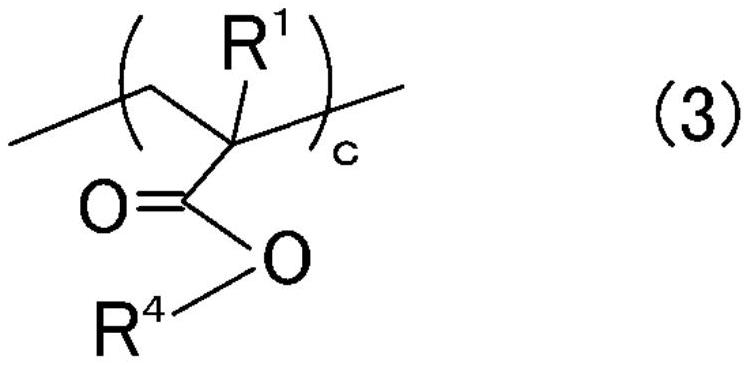

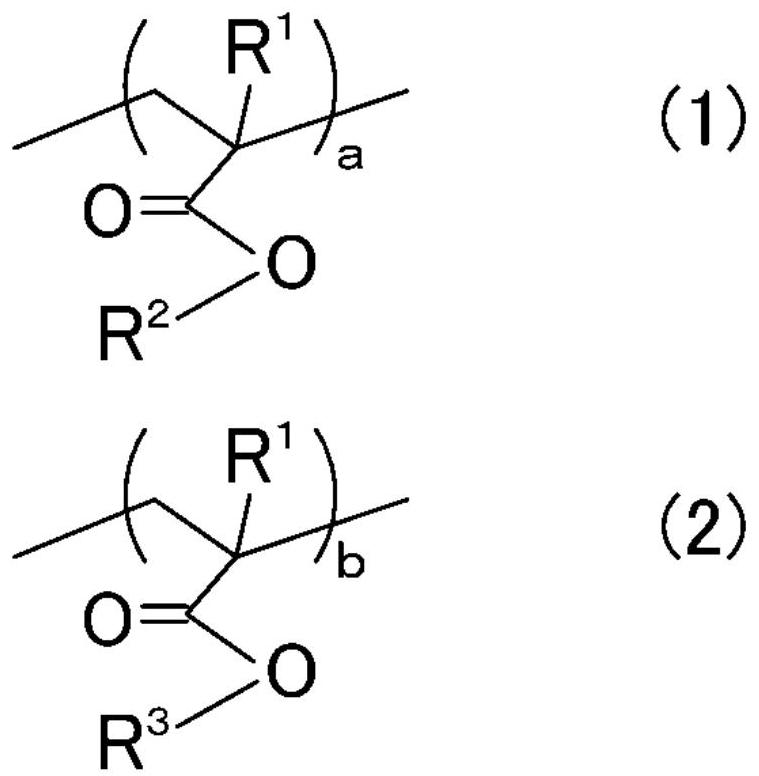

Fluorine-containing polymer particles

A polymer, particle technology, applied in the direction of coating, etc., to achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123]

[0124] Add 300 parts of ion-exchanged water and 0.2 parts of sodium lauryl sulfate into the reactor, and start stirring. Under a nitrogen atmosphere, 0.5 parts of ammonium persulfate was added thereto at 80°C, and 35 parts of 2,2,2-trifluoroethyl methacrylate (3FMA), cyclohexyl methacrylate, and A monomer mixture of 63 parts of ester (CHMA), 2 parts of hydroxyethyl methacrylate (HEMA), 2 parts of sodium lauryl sulfate, and 50 parts of ion-exchanged water, after the dropwise addition, was polymerized for 3 hours to obtain Phase 1 polymer particles.

[0125]

[0126] 300 parts of ion-exchanged water, 10 parts of polymer particles (in terms of solid content) obtained in the first-stage polymerization, and 0.2 parts of sodium lauryl sulfate were charged into the reactor, and stirring was started. Under a nitrogen atmosphere, 0.5 parts of ammonium persulfate was added thereto at 80°C, and 35 parts of 2,2,2-trifluoroethyl methacrylate (3FMA), cyclohexyl methacrylate, a...

Embodiment 2

[0140] Add 300 parts of ion-exchanged water and 0.2 parts of sodium lauryl sulfate into the reactor, and start stirring. Under a nitrogen atmosphere, 0.5 part of ammonium persulfate was added thereto at 80°C, and 50 parts of 2,2,2-trifluoroethyl methacrylate (3FMA), cyclohexyl methacrylate, and Monomer mixture of 24 parts of ester (CHMA), 24 parts of cyclohexyl acrylate (CHA), 2 parts of 4-hydroxybutyl acrylate (4HBA), 2 parts of sodium lauryl sulfate, and 50 parts of ion-exchanged water. , for 3 hours to carry out the polymerization treatment. The pH was adjusted to about 8 with aqueous ammonia. The obtained polymer particles are shown in Table 1.

Embodiment 3

[0142] Except having changed the composition ratio of a monomer mixture into the composition shown in Table 1, it carried out similarly to Example 1, and obtained the polymer particle. The obtained polymer particles are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com