A kind of microbial denitrification method of high-salt sewage

A high-salt sewage and microbial technology, applied in the field of microbial denitrification of high-salt sewage, to achieve strong ammonia nitrogen degradation ability, improve ammonia nitrogen degradation efficiency, and high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Screening of isolated strains

[0055] Selective solid medium: tryptone 5.00g / L; yeast extract 1.00g / L; sodium chloride 19.45g / L; anhydrous MgCl 5.90g / L; Na 2 SO 4 ·10H 2 O 3.24g / L; CaCl 1.80g / L; KCl 0.55g / L; NaHCO 3 0.16g / L; H 3 BO 3 22mg / L; Na 2 HPO 4 8mg / L; agar 15g / L.

[0056] The strains were screened from high-salt sewage from a factory in Lishui, 50 mL of sewage was taken, centrifuged at 12,000 rpm for 10 min, the supernatant was discarded, and water was added to 1 mL and mixed. Add 9 mL of water to form 10 -1 diluent. from 10 -1 Take 1 mL of the dilution solution and add 9 mL of sterile water to make 10 -2 Diluent, and so on, make a series of gradient dilutions on the finally obtained bacterial liquid, and take 0.1 mL of it and spread it on the separation medium, and cultivate at 30°C until a single colony grows. The single colonies with different colors and shapes were streaked and purified, and 6 single colonies were picked. After pur...

Embodiment 2

[0057] Example 2: Ammonia nitrogen degradation ability test of strain

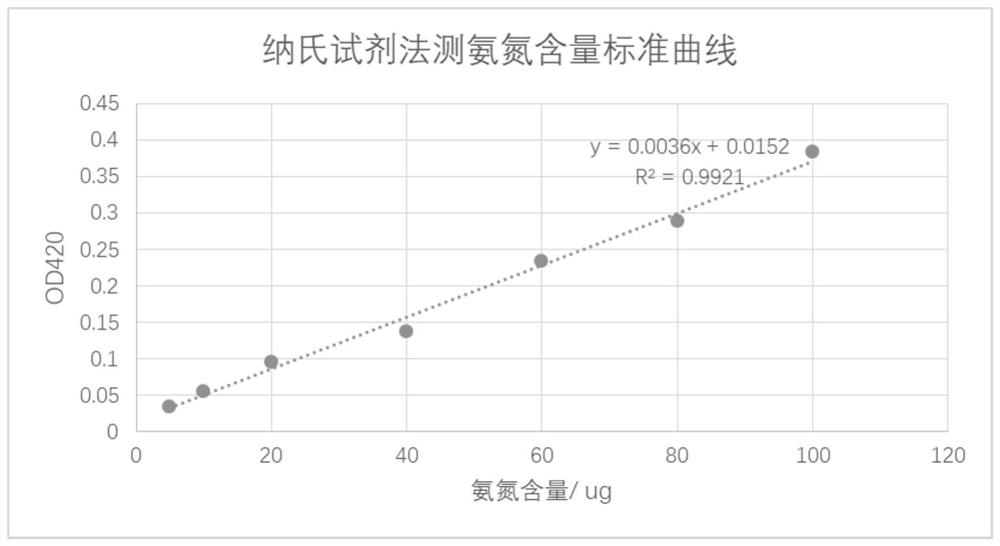

[0058] 1 Ammonia nitrogen standard curve

[0059] In eight 50mL volumetric flasks, add 0.00mL, 0.50mL, 1.00mL, 2.00mL, 4.00mL, 8.00mL, and 10.00mL ammonia nitrogen standard working solutions respectively, and the corresponding ammonia nitrogen contents are 0.0μg, 5.0μg, 10.0 μg, 20.0 μg, 40.0 μg, 60.0 μg, 80.0 μg and 100 μg, add water to the mark. Add 1.0mL potassium sodium tartrate solution, shake well, then add 1.0mL Nessler reagent, shake well. After standing for 10min, at a wavelength of 420nm, use a 10mm cuvette with water as a reference, measure the absorbance, take the absorbance after blank correction as the ordinate, and its corresponding ammonia nitrogen content (μg) as the abscissa, draw a calibration curve, The standard curve obtained as figure 2 shown.

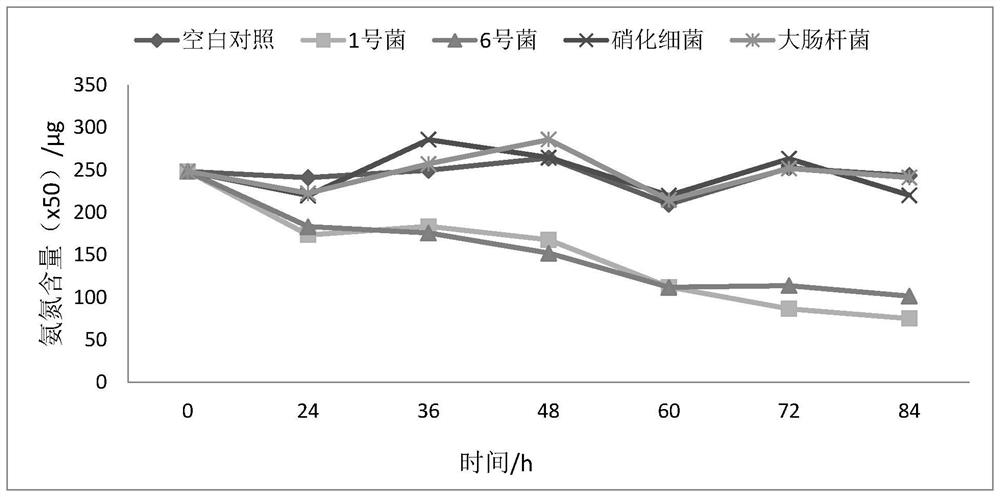

[0060] Ammonia nitrogen degradation ability of 2 strains

[0061] A single colony was picked from the plate and inoculated into a liqui...

Embodiment 3

[0077] Example 3: Salt tolerance test of strains 1 and 6

[0078] 1 Growth curves at different salinities

[0079] The growth curves of strain 1 and strain 6 were detected under salinity of 1%, 4%, 7%, and 10%, respectively. The results are as follows Figure 4 shown. from Figure 4 It can be seen that both strains No. 1 and No. 6 can grow and reproduce under the salinity of 1%-10%.

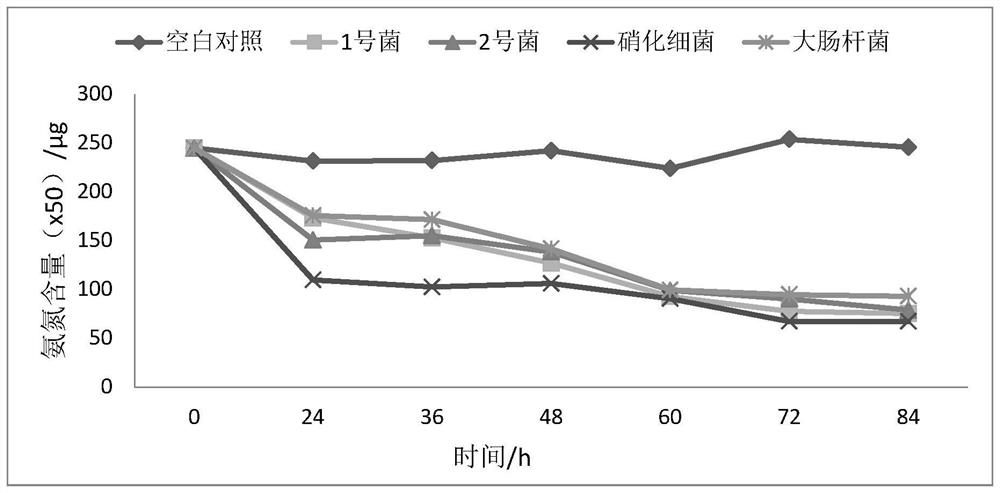

[0080] 2. Ammonia nitrogen degradation ability under different salinity

[0081] Strain No. 1 and No. 6 were inoculated into liquid LB medium, and cultured at 30° C. shaker at 220 rpm for 1 day. Take 2mL of bacterial solution and centrifuge at 12000rpm for 1min, add 1mL of deionized water to resuspend, centrifuge at 12000rpm for 1min to discard the supernatant, and repeat for 4 groups. The precipitates were resuspended with artificial water samples with salinities of 1%, 4%, 7% and 10%, respectively, and then put into 100 mL of corresponding artificial water samples, and incubated at 30°C wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com