Ultralow-loss zirconium magnesium niobate system microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and zirconium magnesium niobate, which is applied in the field of ultra-low loss zirconium magnesium niobate system microwave dielectric ceramic materials and its preparation, can solve the problems of high sintering temperature and lower ceramic quality factor, and achieve simple preparation process, Effects of enhancing lattice energy and bond energy, and increasing grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

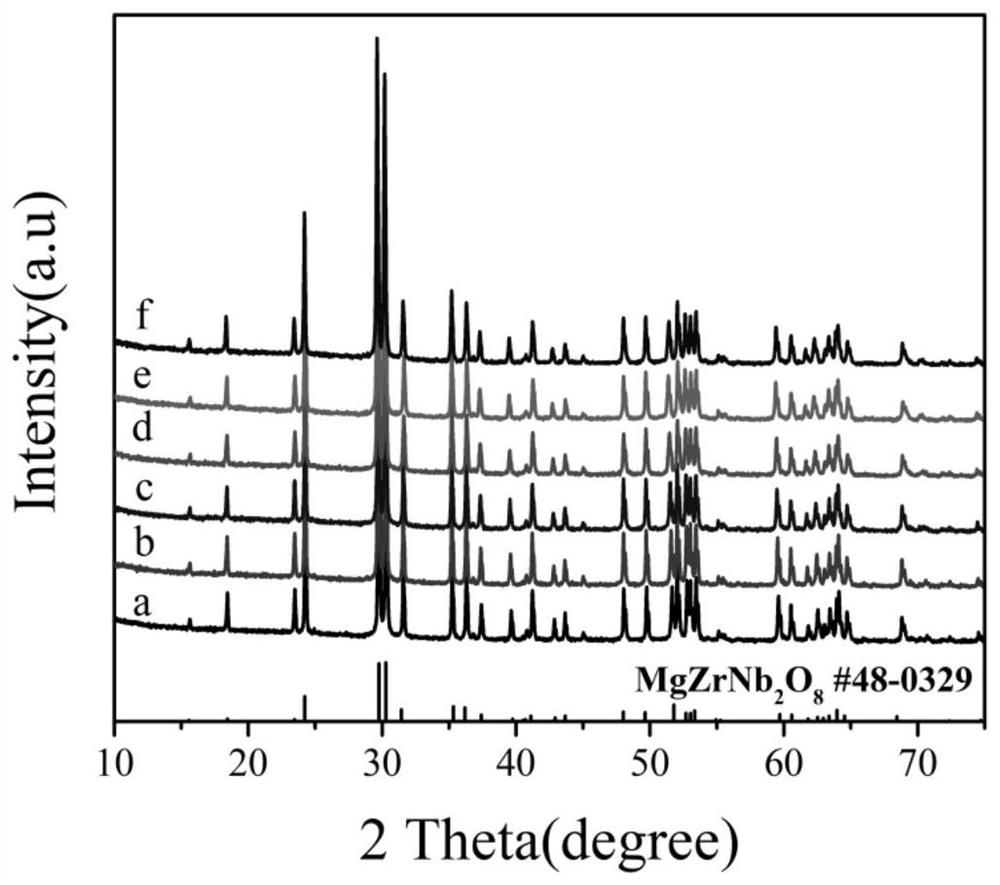

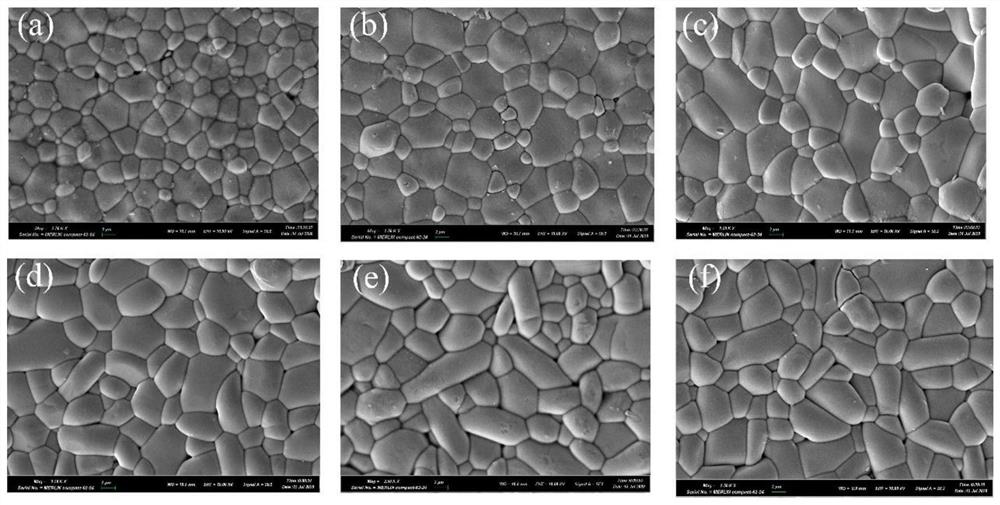

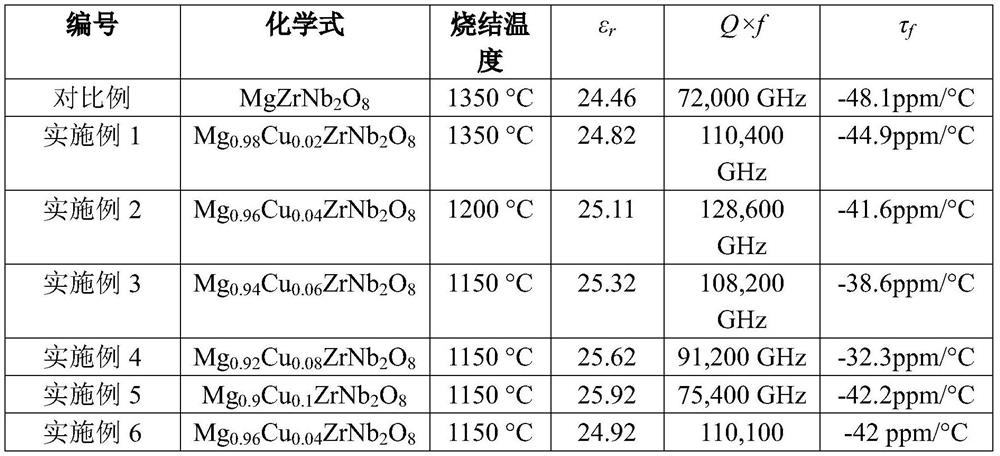

[0040] This embodiment provides a microwave dielectric ceramic material with a chemical formula of Mg 0.98 Cu 0.02 ZrNb 2 o 8 , whose crystal phase is pure phase MgZrNb 2 o 8 . X-ray diffraction (XRD) patterns such as figure 1 In b, the SEM picture is as follows figure 2 b in b; it can be seen from the figure that the grain morphology is polyhedral shape.

[0041] The preparation method of the ultra-low loss zirconium magnesium niobate system microwave dielectric ceramic material comprises the following steps:

[0042] Step 1: batching; raw materials MgO, CuO, ZrO 2 and Nb 2 o 5 According to the chemical formula Mg 0.98 Cu 0.02 ZrNb 2 o 8 , the stoichiometric ratio of the batching, the purity of the raw materials are greater than 99%;

[0043] Step 2: mixing materials; the raw materials obtained in step 1 are ball milled, and the specific ball milling process is: using zirconia balls as the ball milling medium, and deionized water as the solvent, the raw materi...

Embodiment 2

[0050] This embodiment provides a microwave dielectric ceramic material with a chemical formula of Mg 0.96 Cu 0.04 ZrNb 2 o 8 , whose crystal phase is pure phase MgZrNb 2 o 8 . X-ray diffraction (XRD) patterns such as figure 1 In c, the SEM image is as follows figure 2 In c; it can be seen from the figure that the grain morphology is the coexistence of polyhedron and rod shape.

[0051] A method for preparing an ultra-low loss zirconium magnesium niobate system microwave dielectric ceramic material, comprising the following steps:

[0052] Step 1: batching; raw materials MgO, CuO, ZrO 2 and Nb 2 o 5 According to the chemical formula Mg 0.96 Cu 0.04 ZrNb 2 o 8 The stoichiometric ratio is compounded, and the purity of the raw materials is greater than 99%;

[0053] Step 2: mixing materials; the raw materials obtained in step 1 are ball milled, and the specific ball milling process is: using zirconia balls as the ball milling medium, and deionized water as the sol...

Embodiment 3

[0060] This embodiment provides a microwave dielectric ceramic material with a chemical formula of Mg 0.94 Cu 0.06 ZrNb 2 o 8 , whose crystal phase is pure phase MgZrNb 2 o 8 . X-ray diffraction (XRD) patterns such as figure 1 In d, the SEM image is as follows figure 2 d in the figure; it can be seen from the figure that the grain morphology is the coexistence of polyhedron and rod-like shape.

[0061] A method for preparing an ultra-low loss zirconium magnesium niobate system microwave dielectric ceramic material, comprising the following steps:

[0062] Step 1: batching; raw materials MgO, CuO, ZrO 2 and Nb 2 o 5 According to the chemical formula Mg 0.94 Cu 0.06 ZrNb 2 o 8 The stoichiometric ratio is compounded, and the purity of the raw materials is greater than 99%;

[0063] Step 2: mixing materials; the raw materials obtained in step 1 are ball milled, and the specific ball milling process is: using zirconia balls as the ball milling medium and deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com