Clean production process for recycling molybdenum and rhenium from ion adsorption type molybdenum-rhenium ore

An ion adsorption type, clean production technology, applied in the direction of improving process efficiency, can solve the problems of unsuitable treatment of ion adsorption type molybdenum-rhenium ore, high safety requirements, lack of treatment methods, etc., to save long-distance transportation The effect of cost, environmental friendliness, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

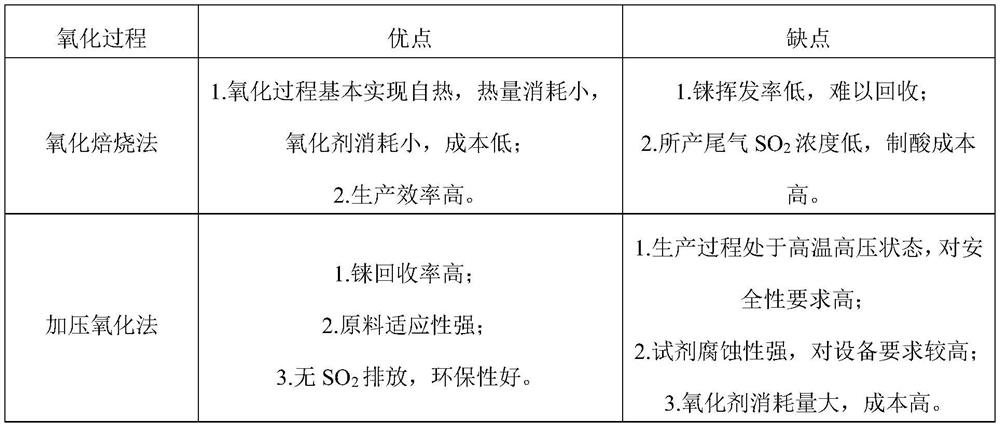

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A process for recovering molybdenum-rhenium from ion-adsorption type molybdenum-rhenium ore, comprising the following steps:

[0037] (1) Grind the ion-adsorption molybdenum-rhenium ore in a vibration mill to a particle size of less than 0.12 mm, then add 2 kg to the reactor;

[0038](2) Add 10L of tap water to the reaction kettle with 3 baffles, add 1.5kg of sodium hydroxide at the same time, heat to 60°C for the first leaching, the leaching time is 2h, and the rotational speed of the axial flow paddle is 80rpm, After the reaction, vacuum filtration was carried out for solid-liquid separation, and the rhenium concentration in the obtained primary leaching solution was 2.09 mg / L, and the molybdenum concentration was 92.91 mg / L.

[0039] (3) Continue to add the ion-adsorbed molybdenum-rhenium ore treated in step (2) into the reaction kettle, add 6L tap water, 900g of sodium hydroxide, 80g of hydrogen peroxide, and 240g of ammonium sulfate at the same time, and heat to 60...

Embodiment 2

[0041] A process for recovering molybdenum-rhenium from ion-adsorption type molybdenum-rhenium ore, comprising the following steps:

[0042] (1) Grind the ion-adsorption molybdenum-rhenium ore in a vibration mill to a particle size of less than 0.12 mm, then add 2 kg to the reactor;

[0043] (2) Add 10L of tap water to the reaction kettle with 3 baffles, add 1.5kg of potassium hydroxide at the same time, heat to 60°C for the first leaching, the leaching time is 2h, and the rotational speed of the axial flow paddle is 80rpm, After the reaction, the solid-liquid separation was carried out by vacuum filtration, and the rhenium concentration in the obtained primary leachate was 2.06mg / L, and the molybdenum concentration was 86.34mg / L;

[0044] (3) continue to add the ion-adsorption type molybdenum-rhenium ore after step (2) processing in the reactor, add the potassium hydroxide of 6L tap water, 900g, the potassium permanganate of 240g, the sodium chloride of 100g simultaneously, b...

Embodiment 3

[0046] A process for recovering molybdenum-rhenium from ion-adsorption type molybdenum-rhenium ore, comprising the following steps:

[0047] (1) Grind the ion-adsorption molybdenum-rhenium ore in a vibration mill to a particle size of less than 0.12 mm, then add 2 kg to the reactor;

[0048] (2) Add 10L of tap water to the reaction kettle with 3 baffles, add 1.5kg of sodium hydroxide at the same time, heat to 60°C for the first leaching, the leaching time is 2h, and the rotational speed of the axial flow paddle is 80rpm, After the reaction, the solid-liquid separation was carried out by vacuum filtration, and the rhenium concentration in the obtained primary leaching solution was 2.18 mg / L, and the molybdenum concentration was 97.41 mg / L.

[0049] (3) Continue to add the ion-adsorbed molybdenum-rhenium ore treated in step (2) into the reactor, add 6L tap water, 900g of sodium hydroxide, 100g of hydrogen peroxide, and 360g of ammonium sulfate at the same time, and heat to 60°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com