Seed crystal pasting jig, flow guide assembly and method for pasting seed crystal on edge

A seed crystal and tooling technology, applied in the field of silicon carbide growth devices, can solve the problems of high difficulty in controlling the amount of pasting glue, easy formation of radial temperature gradients, and high difficulty in taking seed crystals, so as to reduce the risk of artificial crystal defects and reduce planning. damage, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

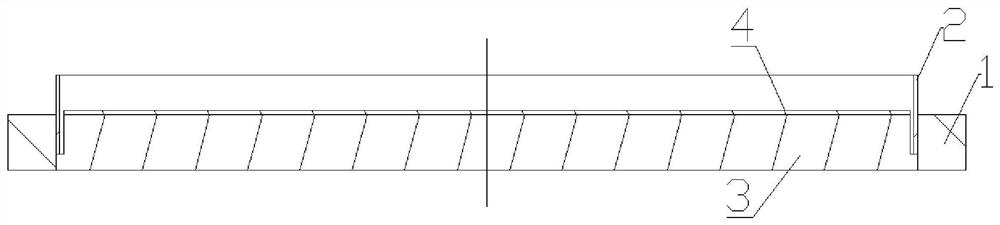

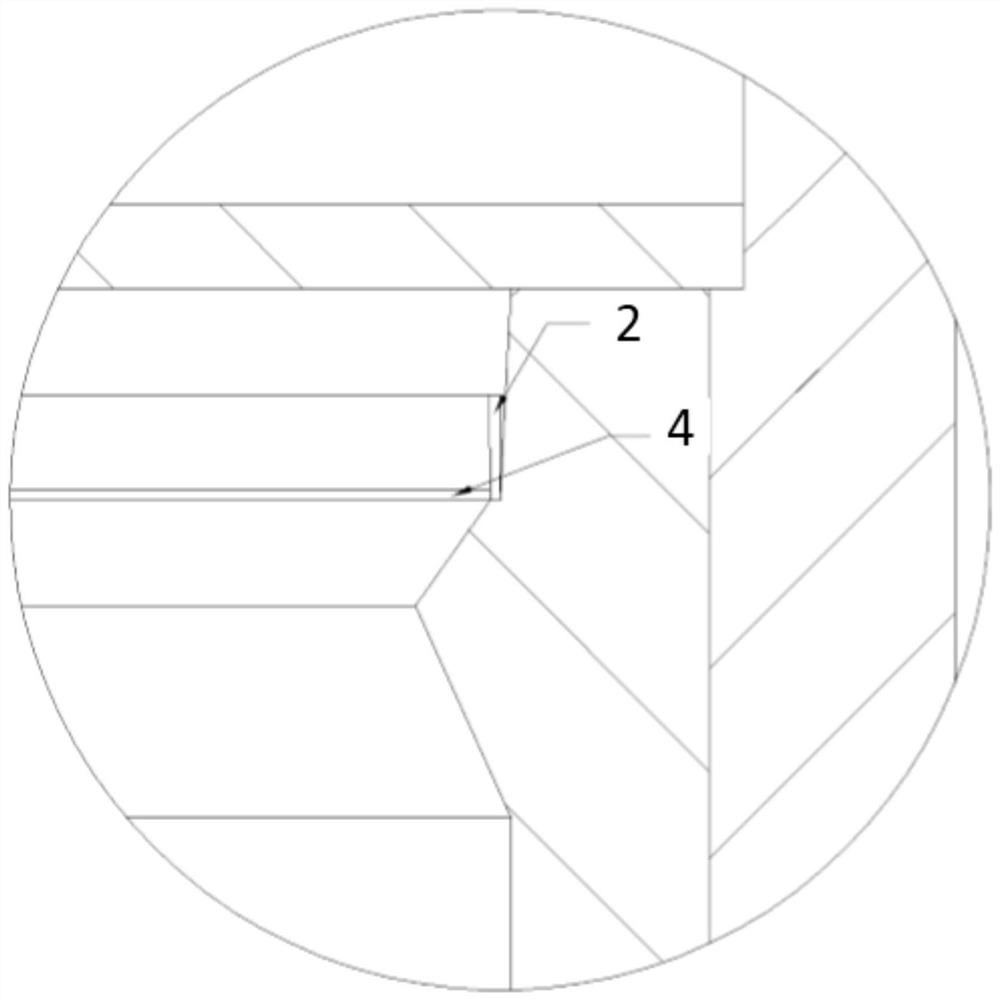

[0044] see figure 1 , the present embodiment provides a seed crystal pasting jig (ie pasting jig 3). A pasting outer ring 1 is provided on the outer periphery of the pasting jig 3 . The pasting jig 3 has a seed crystal bearing surface, and grooves are arranged on the seed crystal bearing surface for pasting graphite paper. Specifically, graphite paper 2 is arranged in the groove, and seed crystals 4 are arranged on the pasting jig 3 . Spatially, the graphite paper 2 ring is arranged around the seed crystal 4, and the shape of the seed crystal 4 is the original sheet.

[0045] The specifications of graphite paper 2 are as follows: the material is high-density graphite paper, the thickness is 0.5-1mm, the width is 15-20mm, and the length is 320-350mm. In this embodiment, the graphite paper 2 is set to have a thickness of 0.5 mm, a width of 15 mm, and a length of 320 mm.

[0046] The specifications of the sticking fixture 3 are as follows: it is made of high-density graphite,...

Embodiment 2

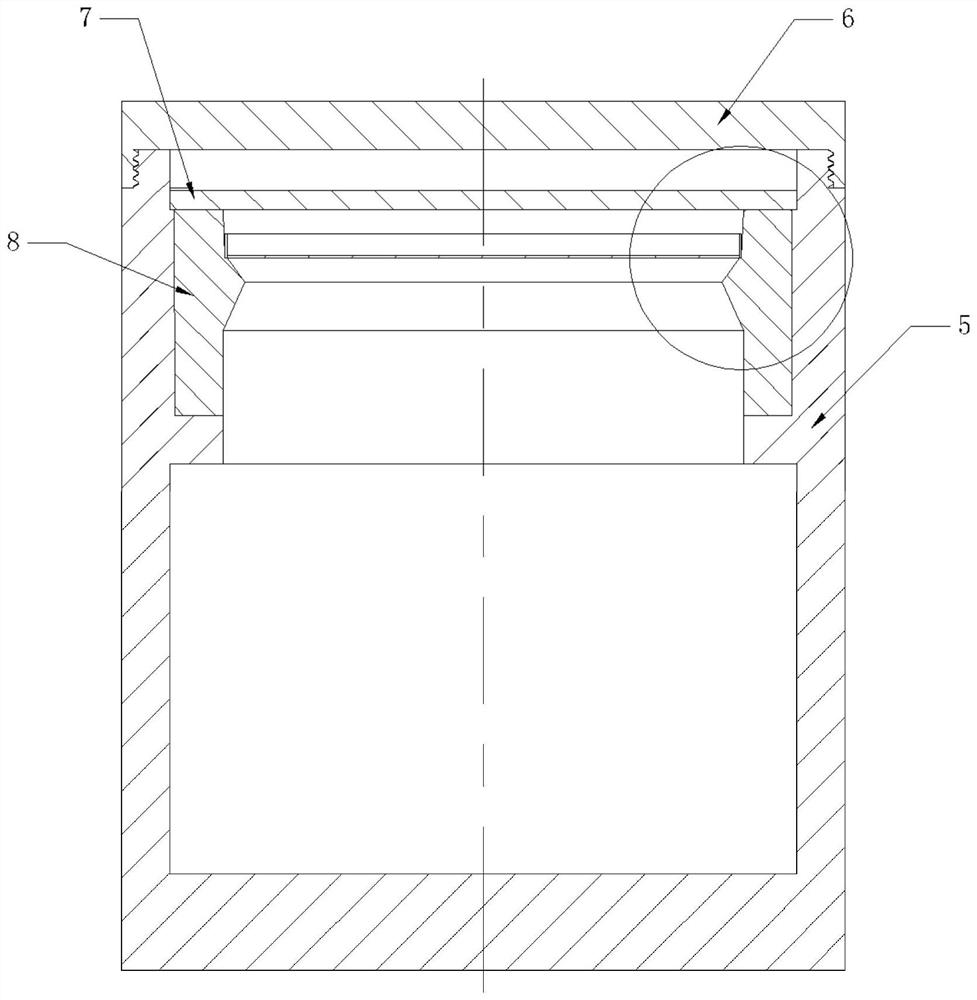

[0050] This embodiment provides a flow guide assembly and a crucible. Guide assembly and crucible reference figure 2 and image 3 shown.

[0051] The diversion assembly includes a seed paste jig, graphite paper 2 and a diversion cylinder 8 . Specifically, the pasting jig 3 for removing and pasting the outer ring 1 in Embodiment 1 is placed in the guide tube 8 . Bond the pasting tool 3 and the guide tube 8 with carbon glue, and then put them into a curing furnace for curing. Then put the cured guide tube 8 into the crucible, and use it to grow the crystal after assembling the thermal field.

[0052] The guide tube 8 in this embodiment is made of high-density graphite with a thickness of 2.95-3.05 mm. The first cavity, the second cavity and the third cavity are arranged in order from top to bottom, the first cavity is a conical cavity, the second cavity is a cavity formed by the combination of two conical structures, and The ends of the two circular platforms with smaller...

Embodiment 3

[0057] This embodiment provides a method for seed crystal growth, which includes: pasting the seed crystal 4 and the graphite paper 2 through the sticking jig 3 , and scraping off the graphite paper 2 put into the sticking jig 3 . Then put the treated seed crystal and graphite paper into the guide tube 8, use carbon glue to paste the graphite paper 2 and the inner wall of the guide tube 8, and put it into a curing furnace for curing. Select the crucible main body 5 with a thickness of 10mm, put 1.25kg of high-purity SIC powder into the barrel of the crucible main body 5, make it as smooth as possible, and then put the barrel of the crucible main body 5 into the cured guide tube 8. Cover the pressing plate 7 and the crucible lid 6. A cylindrical hard felt with a thickness of 1.5 mm is placed outside the crucible as a thermal insulation field.

[0058] The growth direction of the crystal is vertical to the horizontal plane where the seed crystal is located and grows downward. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com