Equipment and method for preparing tetrapod-like zinc oxide whiskers by using modified montmorillonite catalyst

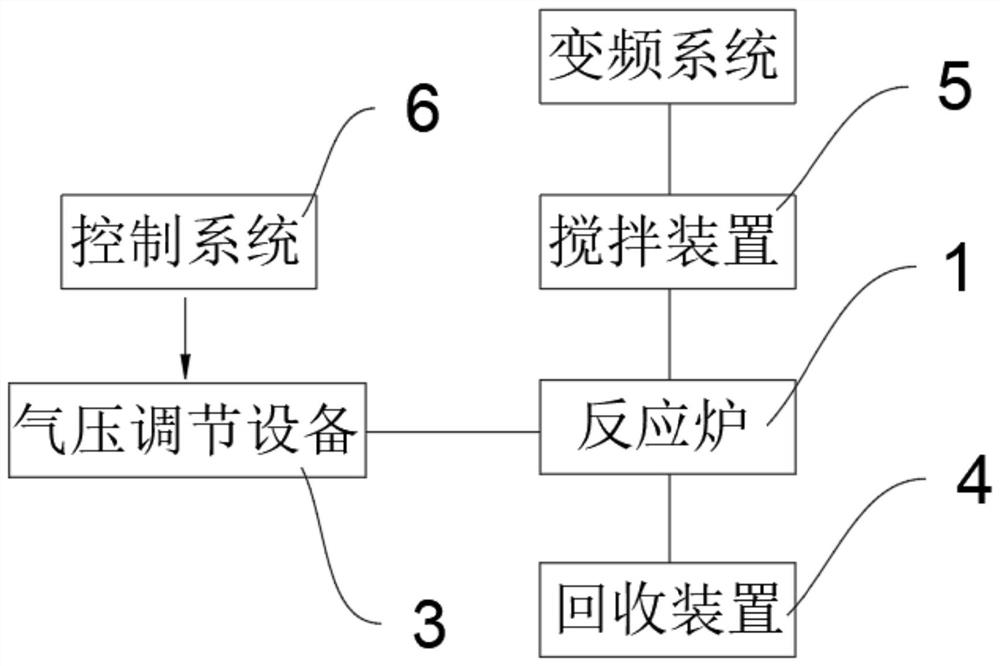

A four-needle zinc oxide and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, single crystal growth, etc., can solve the problem that T-ZnOw is difficult to achieve large-scale production, product purity and quality cannot be effectively guaranteed, Low whisker conversion rate and other problems, to achieve the effect of reducing labor burden, good whisker growth, and uniform whisker size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

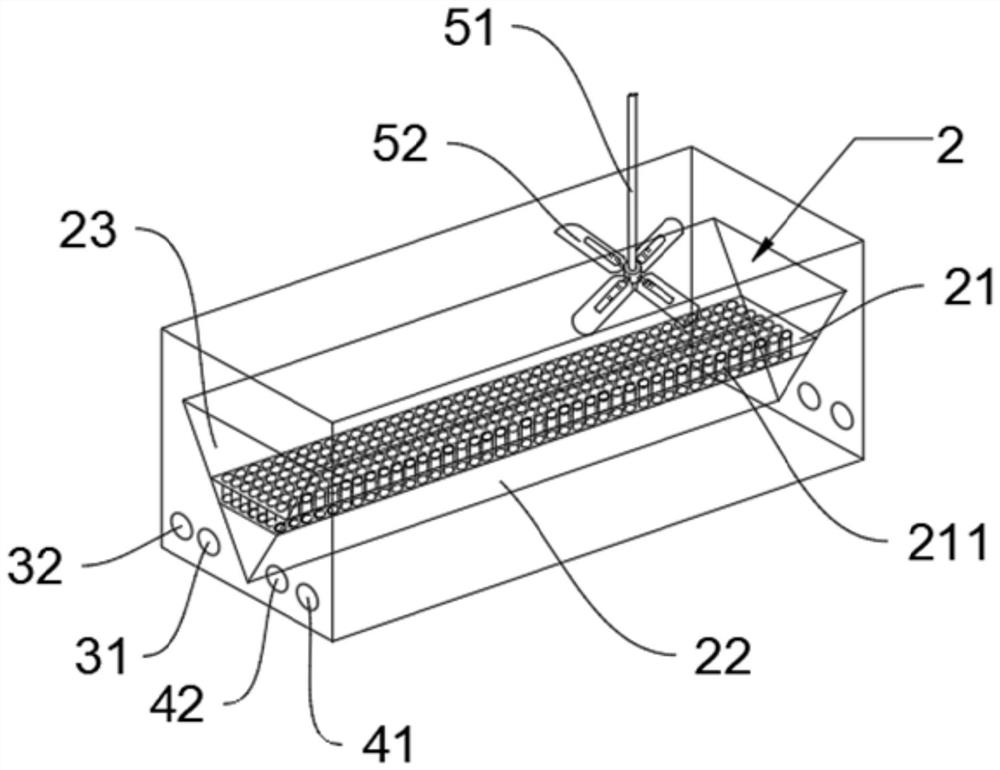

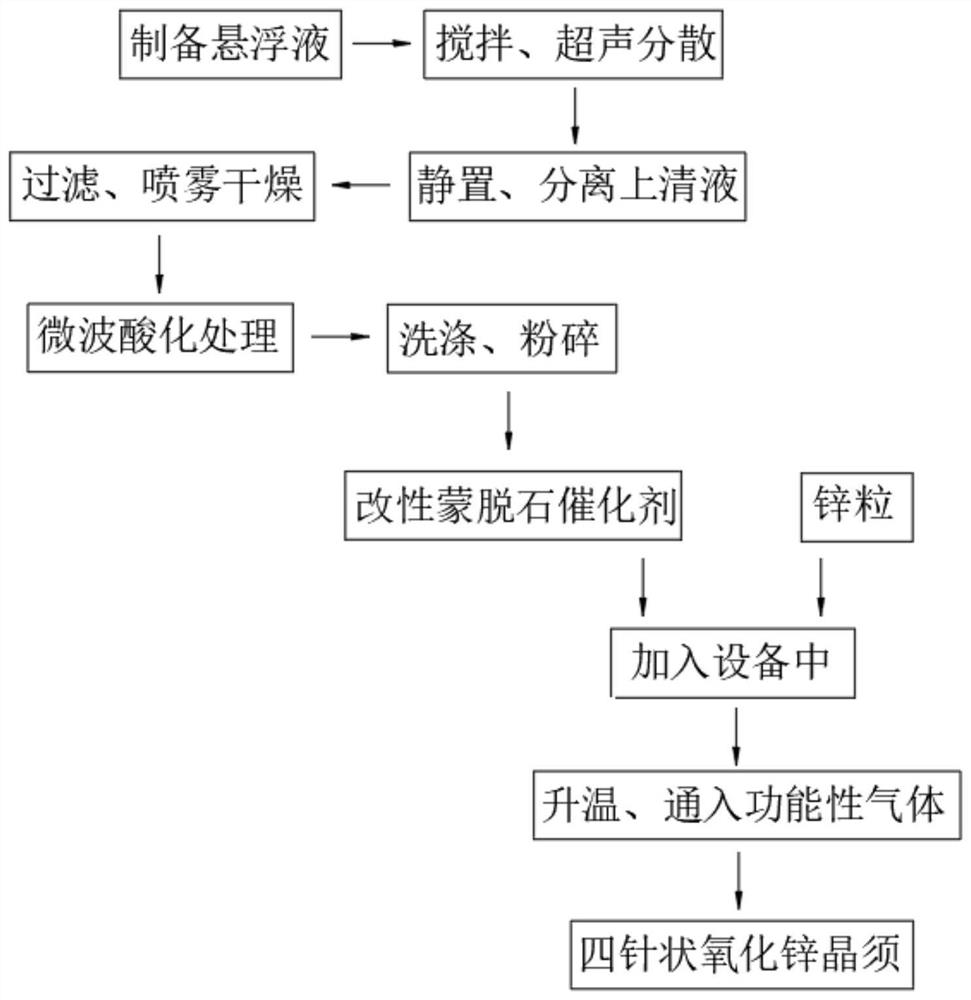

[0061] The present invention adopts modified montmorillonite as a catalyst to prepare tetraacicular zinc oxide whiskers, comprising the following steps:

[0062] S1: Put the modified montmorillonite catalyst into the catalyst bin from the catalyst bin mouth, preheat 500°C-1100°C, wherein the mass fraction of montmorillonite is 90.5%;

[0063] S2: Zinc particles are put into the raw material bin, and heated by a heater to make it equal to the temperature of the catalyst bin, and the purity of the zinc particles is 99%;

[0064] S3: The catalyst enters the raw material material bin through the connection hole on the isolation plate in the form of steam, and the zinc vapor is combined in the upper layer of the material bin;

[0065] S4: Use the intelligent frequency conversion system to control the rotation speed of the stirring blade to 5-15 rpm to fully mix the catalyst vapor and zinc vapor, and accelerate the growth of zinc oxide crystals through positive charge ion exchange. ...

Embodiment 2

[0075] The difference between embodiment 2 and embodiment 1 is only that the mass fraction of montmorillonite in the modified smectite catalyst is 78%, and the rest of the steps are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com