Preparation method, product and application of nano magnesium oxide

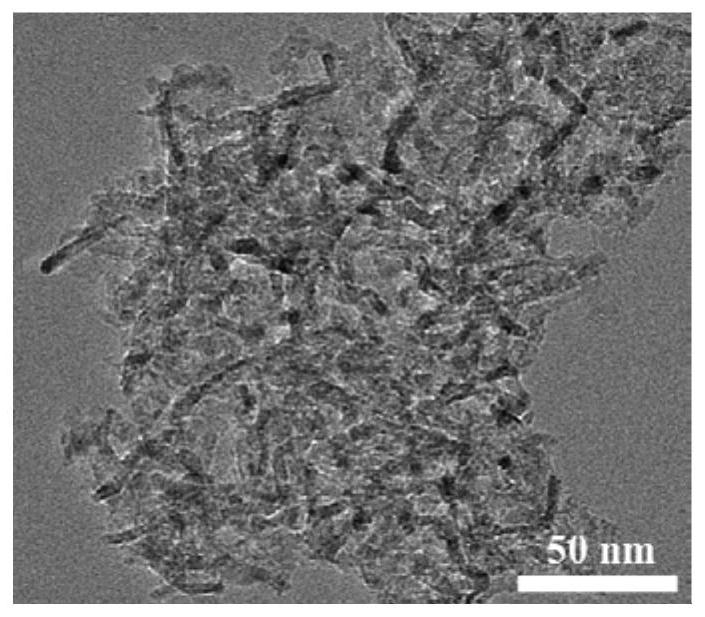

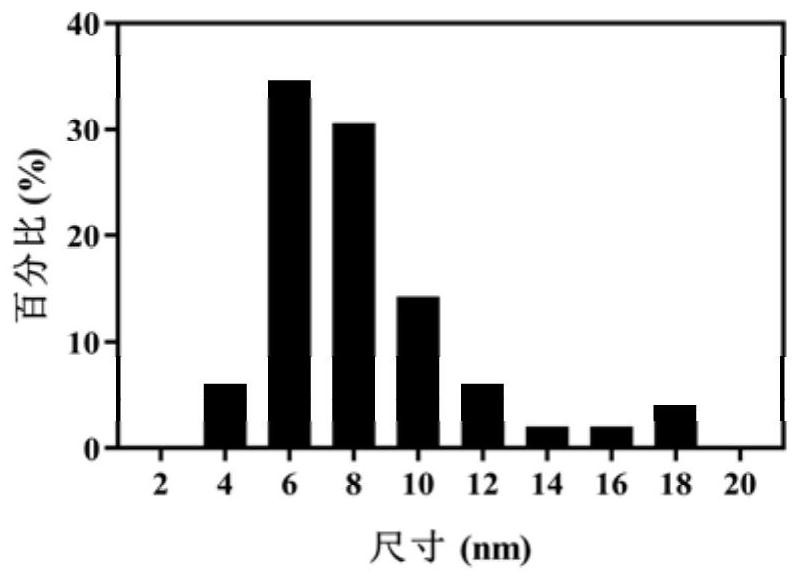

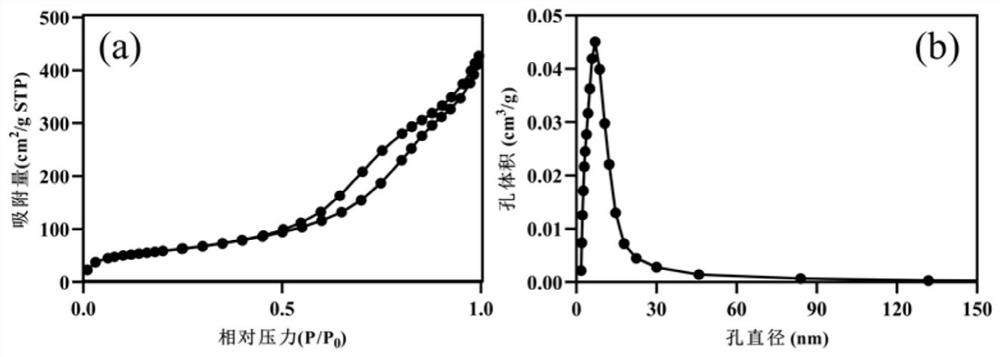

A technology of nano-magnesium oxide and magnesium hydroxide, which is applied in the field of environmental protection and purification, can solve the problems of high energy consumption, unfavorable industrialization, cost reduction, and long grain time, and achieve uniform particle size distribution, excellent effect, and particle size small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention innovatively adopts magnesium methoxide as the starting material, and provides a preparation method of nano-magnesium oxide, which has the technical advantages of high efficiency, rapidity, and energy saving, and can prepare nano-magnesium oxide with small particle size, large specific surface area and particle size distribution. Uniform nano magnesium oxide. Include the following steps:

[0027] S1, using magnesium methoxide as a raw material to prepare magnesium hydroxide sol;

[0028] S2. Heating the magnesium hydroxide sol to 130-155°C at a constant heating rate and keeping it warm to obtain a magnesium hydroxide wet gel, and drying to obtain a magnesium hydroxide gel; a constant heating rate means that the fluctuation value of the heating rate is less than 1°C ;

[0029] S3, sintering the magnesium hydroxide xerogel to obtain nano magnesium oxide.

[0030] In a specific embodiment, the preparation method of magnesium hydro...

Embodiment 1

[0064] First, 50 mL of 7wt% Mg(OCH 3 ) 2 Add it into 120mL of toluene and perform magnetic stirring, and then add 1.5mL of deionized water dropwise to the above solution. Finally, react overnight at room temperature to obtain Mg(OH) in the gel state of the hydrolyzate 2 . Strain and wash two or three times.

[0065] Then the resulting gel-state Mg(OH) 2 The product was put into the closed autoclave of the microwave chemical synthesizer, and the multi-purpose microwave chemical synthesizer was used to directly input the initial temperature of 25°C, the final temperature of 150°C, the heating time of 20min, the holding time of 20min, and the heating rate of 6.25°C / min. During the heating and heat preservation process, the microwave power fluctuates in the range of 0-400W, and the pressure in the closed autoclave fluctuates in the range of 0-3MPa. After the microwave hydrothermal reaction is over, the product is cooled and filtered, washed with methanol for 3 to 4 times, d...

Embodiment 2

[0072] First, 40 mL of 10 wt% Mg(OCH 3 ) 2 Added to 130mL toluene and magnetically stirred, and then added dropwise 2mL deionized water to the above solution. Finally, react overnight at room temperature to obtain Mg(OH) in the gel state of the hydrolyzate 2 . Strain and wash two or three times. Then the resulting gel-state Mg(OH) 2 The product was put into the airtight autoclave of the microwave chemical synthesizer, and the multi-purpose microwave chemical synthesizer was used to directly input the initial temperature of 25°C, the final temperature of 155°C, the heating time of 30min, the holding time of 30min, and the heating rate of 4.83°C / min. During the heating and heat preservation process, the microwave power fluctuates in the range of 0-400W, and the pressure in the closed autoclave fluctuates in the range of 0-3MPa. After the microwave hydrothermal reaction is over, the product is cooled and filtered, washed with methanol for 3 to 4 times, dried in an oven ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com