A kind of ceramic roller for tempered glass furnace and its manufacturing process

A tempered glass and manufacturing process technology, applied in glass manufacturing equipment, manufacturing tools, glass tempering, etc., can solve problems such as poor strength of ceramic roller rods, achieve simple and easy production methods, improve hardness and strength, and improve compactness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

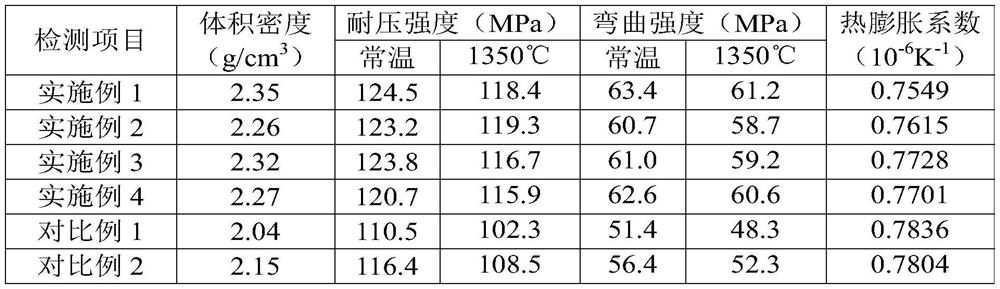

Examples

Embodiment 1

[0028] A kind of ceramic roller for tempered glass furnace and its manufacturing process

[0029] The manufacturing process of ceramic roller for tempered glass furnace includes the following steps:

[0030] Step S10, prepare materials: 30kg of mullite, 32kg of alumina, 12kg of refractory clay, 14kg of kaolin, 6.5kg of zirconium silicate, 1.4kg of talc, 1.5kg of vanadium pentoxide, 2.0kg of boron nitride and 1.1kg of magnesium oxide; Mullite is light-fired mullite with particle size ≤ 10μm and fused mullite with particle size ≤ 1mm, and the weight ratio of light-burned mullite and fused mullite is 20:80; the above alumina is particle size ≤ 1mm 10μm fused alumina and ordinary alumina with a particle size of ≤1mm, the weight ratio of fused alumina and ordinary alumina is 40:60;

[0031] Step S20, the above-mentioned weight parts of alumina, refractory clay, kaolin, zirconium silicate, talc, vanadium pentoxide, boron nitride and magnesium oxide are put into a ball mill for ball...

Embodiment 2

[0036] A kind of ceramic roller for tempered glass furnace and its manufacturing process

[0037] The manufacturing process of ceramic roller for tempered glass furnace includes the following steps:

[0038] Step S10, prepare materials: 20kg of mullite, 20kg of alumina, 6kg of refractory clay, 8kg of kaolin, 3kg of zirconium silicate, 0.8kg of talc, 0.4kg of vanadium pentoxide, 1.2kg of boron nitride and 0.4kg of magnesium oxide; The mullite is light-fired mullite with particle size ≤10μm and fused mullite with particle size ≤1mm, and the weight ratio of light-burned mullite and fused mullite is 10:90; the above alumina is particle size ≤10μm The weight ratio of fused alumina and ordinary alumina is 30:70;

[0039] Step S20, the above-mentioned weight parts of alumina, refractory clay, kaolin, zirconium silicate, talc, vanadium pentoxide, boron nitride and magnesium oxide are put into a ball mill for ball milling for 6 hours, and the above-mentioned weight parts of mullite ar...

Embodiment 3

[0044] A kind of ceramic roller for tempered glass furnace and its manufacturing process

[0045] The manufacturing process of ceramic rollers for tempered glass furnace includes the following steps:

[0046] Step S10, prepare materials: 40kg of mullite, 45kg of alumina, 18kg of refractory clay, 20kg of kaolin, 10kg of zirconium silicate, 2.0kg of talc, 2.5kg of vanadium pentoxide, 2.8kg of boron nitride and 1.8kg of magnesium oxide; The mullite is light-fired mullite with particle size ≤ 10μm and fused mullite with particle size ≤ 1mm, and the weight ratio of light-burned mullite and fused mullite is 30:70; the above alumina is particle size ≤ 10μm The weight ratio of fused alumina and ordinary alumina is 50:50;

[0047] Step S20, put the alumina, refractory clay, kaolin, zirconium silicate, talc, vanadium pentoxide, boron nitride and magnesium oxide of the above-mentioned parts by weight into a ball mill for ball milling for 10 hours, add the mullite of the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com