Preparation method of vitamin A acetate

A vitamin and acetate technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the problems of difficult waste alkali treatment, large amount of alkali catalyst, and many by-products , to achieve the effect of easy separation, saving process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

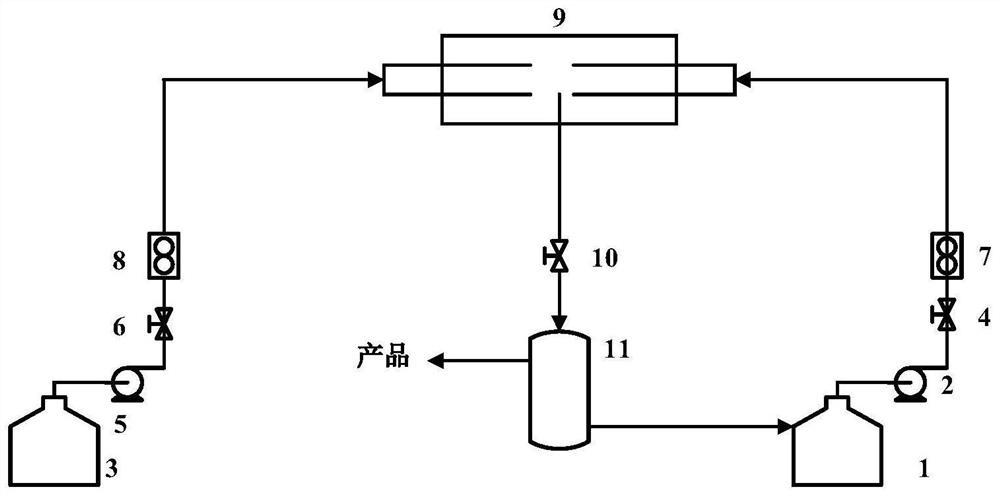

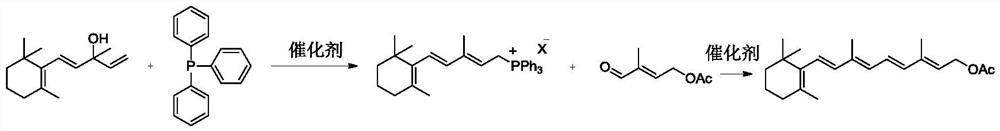

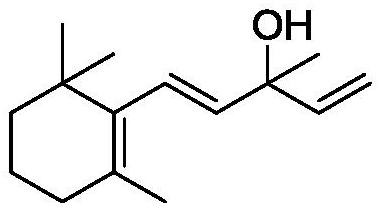

Method used

Image

Examples

Embodiment 1

[0044] Catalyst preparation:

[0045] (1) Dissolve 0.05mol of copper hexacyanocobaltate(III) in 31mL of water / ethanol (the volume ratio of water to ethanol is 0.2:1), stir and dissolve, then feed nitrogen and heat up to 50°C with an oil bath After ℃, 69.0 g of 10 wt % potassium carbonate aqueous solution was added dropwise, and the dropping time was controlled to be 30 min. After the dropwise addition, the system was refluxed at 100° C. for 2 h. The obtained solid was filtered and dried, and then sealed with nitrogen for use, and recorded as solid one.

[0046] (2) Put 10g of activated carbon in 50mL, 10wt% sodium methoxide aqueous solution, stir and stand at 150°C for 3h, add 10g of PVP to the solution, stir vigorously and let stand for 2h, take out the solid and dry it. Recorded as solid two.

[0047] (3) Add 5 g of toluenesulfonic acid into 10 mL of methanol at 0° C., stir evenly, measure the pH of the system to be 3, and let it stand for use. Take 10g of the solid 2 pre...

Embodiment 2

[0050] Catalyst preparation:

[0051] (1) Dissolve 0.1 mol of copper hexacyanocobaltate (III) in 62 mL of water / ethanol (the volume ratio of water to ethanol is 0.3:1), stir and dissolve, then feed nitrogen and heat up to 100 °C with an oil bath After ℃, 138g, 10wt% potassium carbonate aqueous solution was added dropwise, and the dropping time was controlled to be 40min. After the dropwise addition, the system was refluxed at 120℃ for 4h. The obtained solid was filtered and dried, and then sealed with nitrogen for use, and recorded as solid one.

[0052] (2) Put 10g of activated carbon in 100mL, 15wt% sodium methoxide aqueous solution, stir and let it stand at 200°C for 4h, add 20g of PVP to the solution, stir vigorously and let it stand for 4h, take out the solid and dry it. Recorded as solid two.

[0053] (3) Add 5 g of toluenesulfonic acid into 10 mL of methanol at 1° C., stir evenly, measure the pH of the system to be 3.5, and let it stand still for use. Take 10g of the...

Embodiment 3

[0056] Catalyst preparation:

[0057] (1) Dissolve 0.1 mol of copper hexacyanocobaltate (III) in 62 mL of water / ethanol (the volume ratio of water to ethanol is 0.4:1), stir and dissolve, then feed nitrogen and heat up to 150 with an oil bath After ℃, 61g, 20wt% potassium carbonate aqueous solution was added dropwise, and the dropping time was controlled to be 50min. After the dropwise addition, the system was refluxed at 150℃ for 5h. The obtained solid was filtered and dried, and then sealed with nitrogen for use, and recorded as solid one.

[0058] (2) Put 10g of activated carbon in 70mL, 15wt% sodium methoxide aqueous solution, stir and let stand at 250°C for 5h, add 30g of PVP to the solution, stir vigorously and let stand for 6h, take out the solid and dry it, and the obtained solid Recorded as solid two.

[0059] (3) 10 g of toluenesulfonic acid was added into 33.3 ml of methanol at 2° C., and the pH of the system was measured to be 3.9 after stirring evenly. Take 10g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com