Preparation method of bacterial cellulose, bacterial cellulose-chitosan composite gel skincare mask and preparation method thereof

A technology of bacterial cellulose membrane and bacterial cellulose, applied in the field of bacterial cellulose, can solve the problems of not conforming to the bionic design characteristics of human face, poor skin affinity, rising production cost, etc., and achieves high cost performance, reduced production cost, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of bacterial cellulose is characterized in that: comprises the following steps:

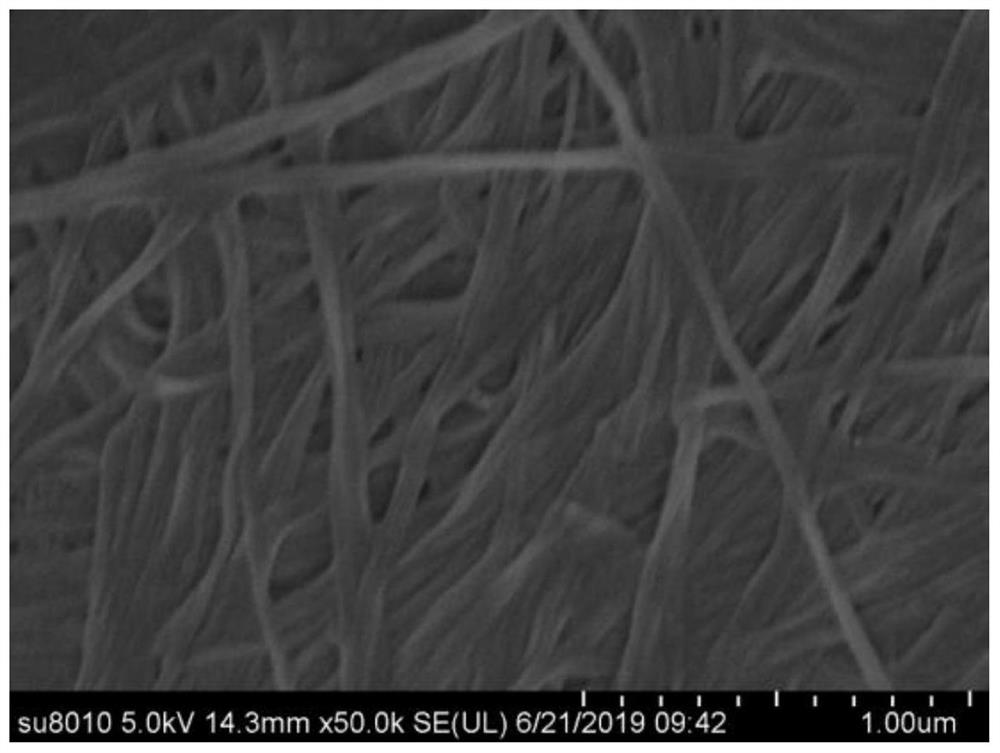

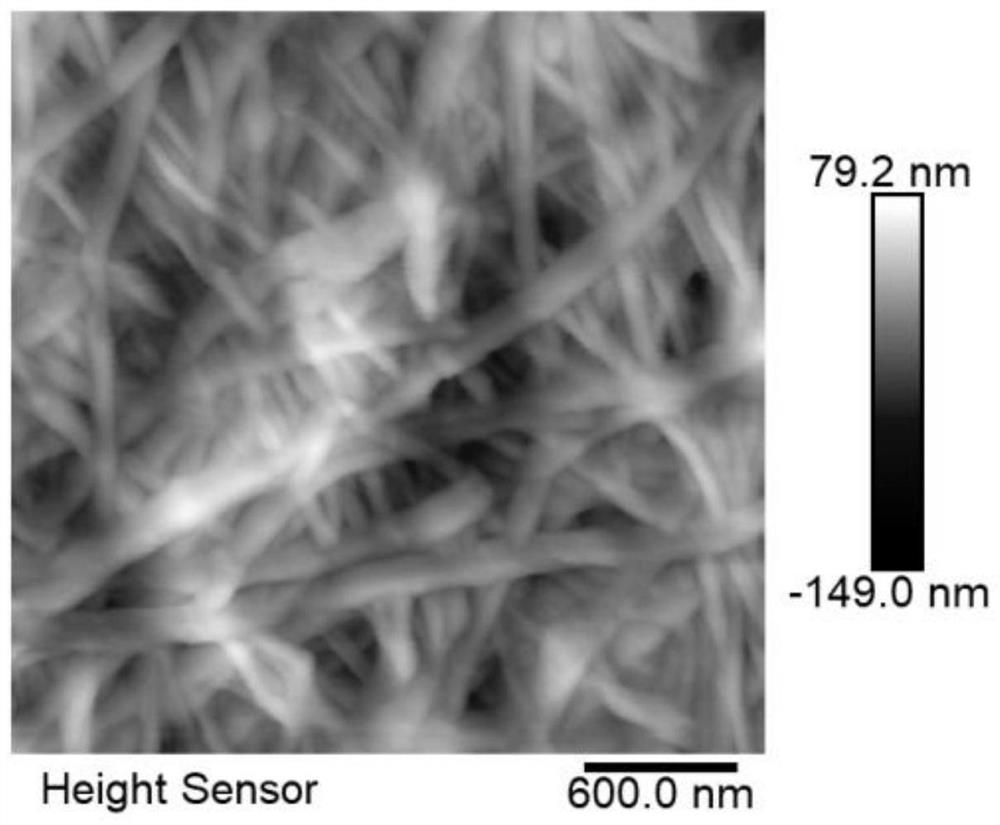

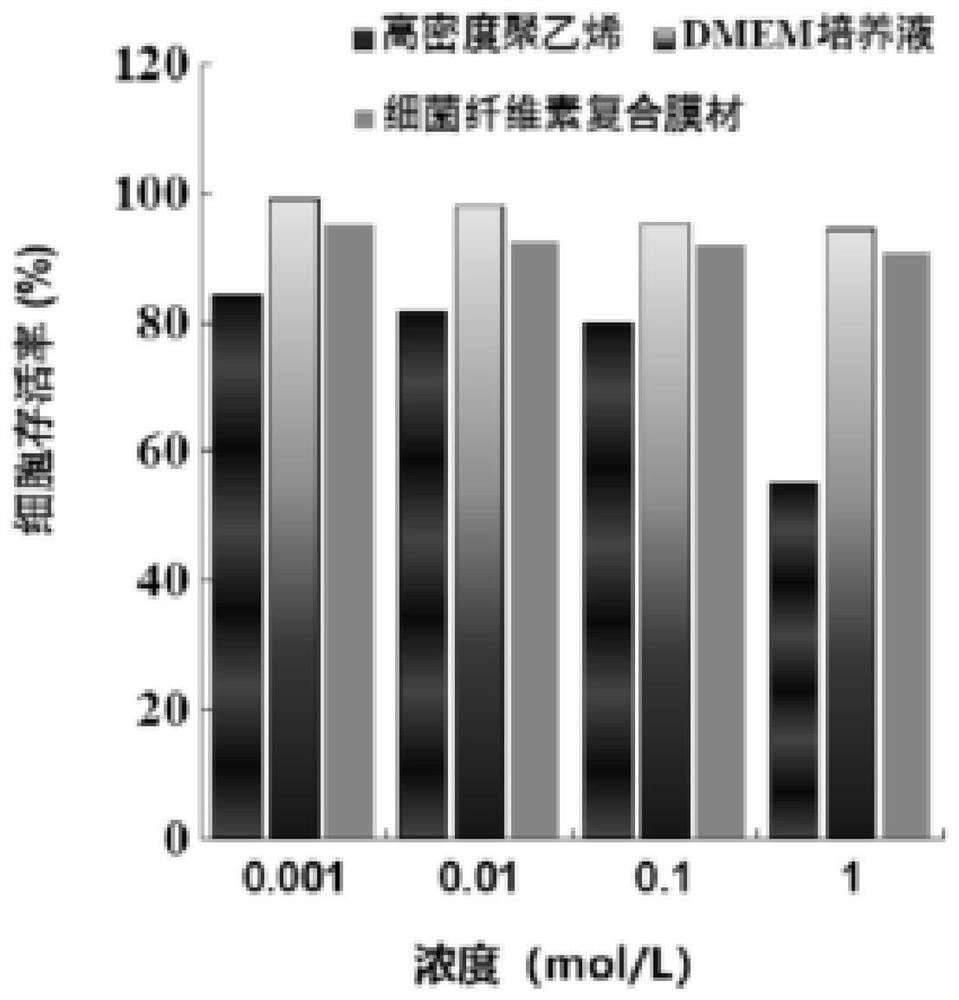

[0030] S01, preparation of bacterial cellulose membrane material: use the by-product residue after soybean protein extraction as the basic raw material, referred to as soybean residue, use soybean residue to prepare soybean residue bio-fermentation medium, add 15% wood to the soybean residue bio-fermentation medium For each 100mL of soybean residue bio-fermentation medium, add 20mL of Gluconacetobacter xylinum seed solution and bitter almond enzyme, pH 5.5, culture temperature 30°C, culture time 15 days, dosage of bitter almond enzyme 300U / mL , to obtain bacterial cellulose membrane material;

[0031] S02, take the bacterial cellulose membrane material, wash it with distilled water several times (specifically 3 times), then immerse it in 0.1mol / mL NaOH solution, soak it in a water bath at 80°C, and stir it magnetically at 100rpm / min for 2h to remove the remaini...

Embodiment 2

[0071] A method for preparing bacterial cellulose, comprising the following steps:

[0072] S01, preparation of bacterial cellulose membrane material: use the by-product residue after soybean protein extraction as the basic raw material, referred to as soybean residue, use soybean residue to prepare soybean residue bio-fermentation medium, add 10% wood to the soybean residue bio-fermentation medium For each 100mL of soybean residue bio-fermentation medium, add 12mL of Gluconacetobacter xylinum seed liquid and bitter almond enzyme, pH 4.8, culture temperature 28°C, culture time 12 days, the amount of bitter almond enzyme 150U / mL , to obtain bacterial cellulose membrane material;

[0073] S02, take the bacterial cellulose membrane material, wash it with distilled water several times, then immerse it in 1mol / mL NaOH solution, soak it in a water bath at 70°C, and stir it magnetically at 90rpm / min for 3h, remove the remaining bacteria and culture medium, take it out and wash it, T...

Embodiment 3

[0083] A method for preparing bacterial cellulose, comprising the following steps:

[0084] S01, preparation of bacterial cellulose membrane material: use the by-product residue after soybean protein extraction as the basic raw material, referred to as soybean residue, use soybean residue to prepare soybean residue bio-fermentation medium, add 18% wood to the soybean residue bio-fermentation medium For each 100mL of soybean residue bio-fermentation medium, add 25mL of Gluconacetobacter xylinum seed solution and bitter almond enzyme, pH 6.0, culture temperature 35°C, culture time 18 days, dosage of bitter almond enzyme 450U / mL , to obtain bacterial cellulose membrane material;

[0085] S02, take the bacterial cellulose membrane material, wash it with distilled water several times, then immerse it in 0.5mol / mL NaOH solution, soak it in a water bath at 90°C, and stir it magnetically at 120rpm / min for 2h, remove the remaining bacteria and culture medium, take it out and wash it ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com