Hollow core-shell antimony-carbon composite negative electrode material, preparation method thereof and secondary battery

A technology for negative electrode materials and secondary batteries, which is applied in the direction of secondary batteries, negative electrodes, battery electrodes, etc., can solve the problems of high preparation cost, complicated method, and high volume expansion rate of antimony-based negative electrode materials, and achieve high Effects of antimony component utilization, simple operation, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A first aspect of the embodiments of the present application provides a method for preparing a hollow core-shell type antimony-carbon composite negative electrode material, comprising the following steps:

[0031] S10. Obtain antimony oxide compound, disperse antimony oxide group and polymerizable monomer in water, add an oxidant to carry out a polymerization reaction, and obtain an antimony oxide compound coated with polymer;

[0032] S20. Perform thermal reduction treatment on the polymer-coated antimony oxide compound to obtain a hollow core-shell type antimony-carbon composite negative electrode material.

[0033]The method for preparing a hollow core-shell type antimony-carbon composite negative electrode material provided in the first aspect of the present application, through an oxidative polymerization reaction, polymerizable monomers are polymerized on the surface of an oxo antimonide to form a polymer coating layer, and a polymer-coated antimony compound is obt...

Embodiment 1

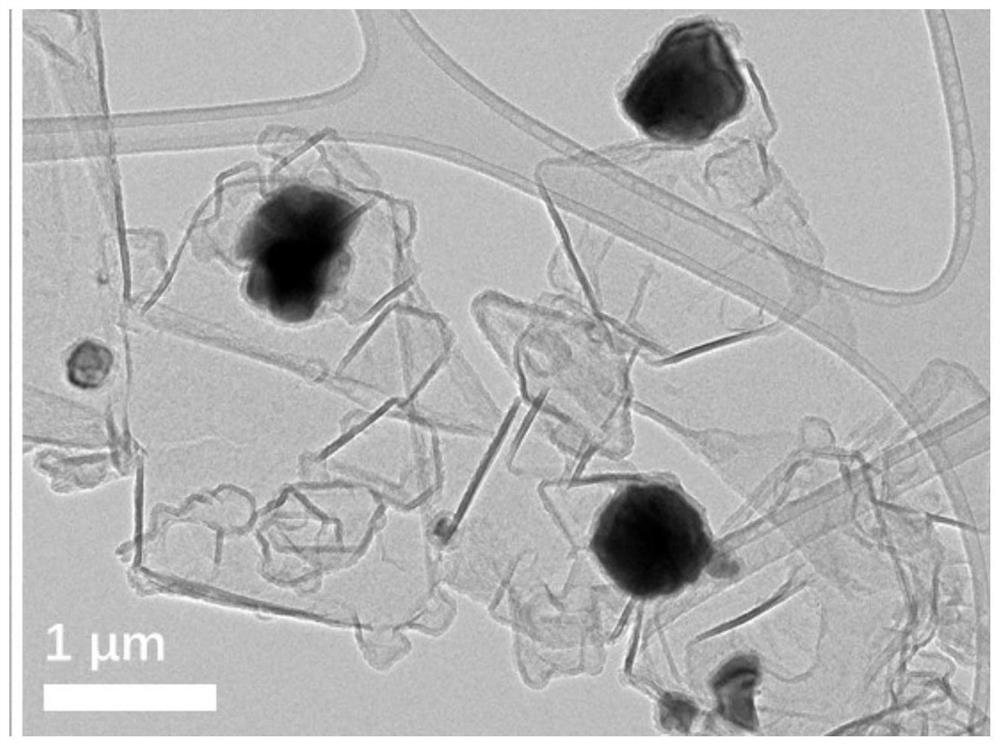

[0060] A hollow core-shell type antimony carbon composite negative electrode material, the preparation of which comprises the steps of:

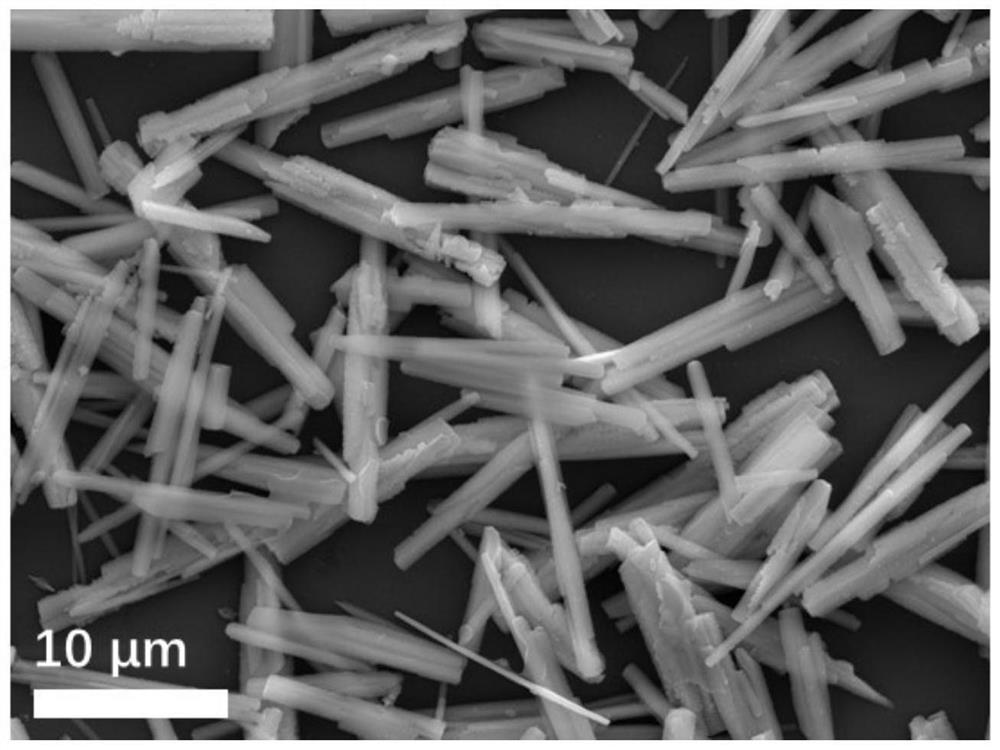

[0061] (1) Preparation of rod-shaped antimony oxide

[0062] Dissolve 70ml ethylenediamine (purity ≥99%) and 4g polyvinylpyrrolidone (purity ≥99%, average molecular weight 24000) in deionized water, add 4g crude elemental antimony powder (30 mesh, purity ≥99%), Stir at room temperature until the suspension changes from gray to milky white, and no black antimony particles settle at the bottom after standing for a while. After the reaction, the suspension was filtered to obtain a precipitate, which was washed twice with water and then dried to obtain rod-shaped antimony oxide.

[0063] (2) Polypyrrole coating of rod-shaped antimony oxide

[0064] The rod-shaped antimony oxide (2 g) prepared in the previous step was dispersed in deionized water (200 mL) to obtain a milky white suspension, followed by adding an appropriate proportion of pyrrol...

Embodiment 2

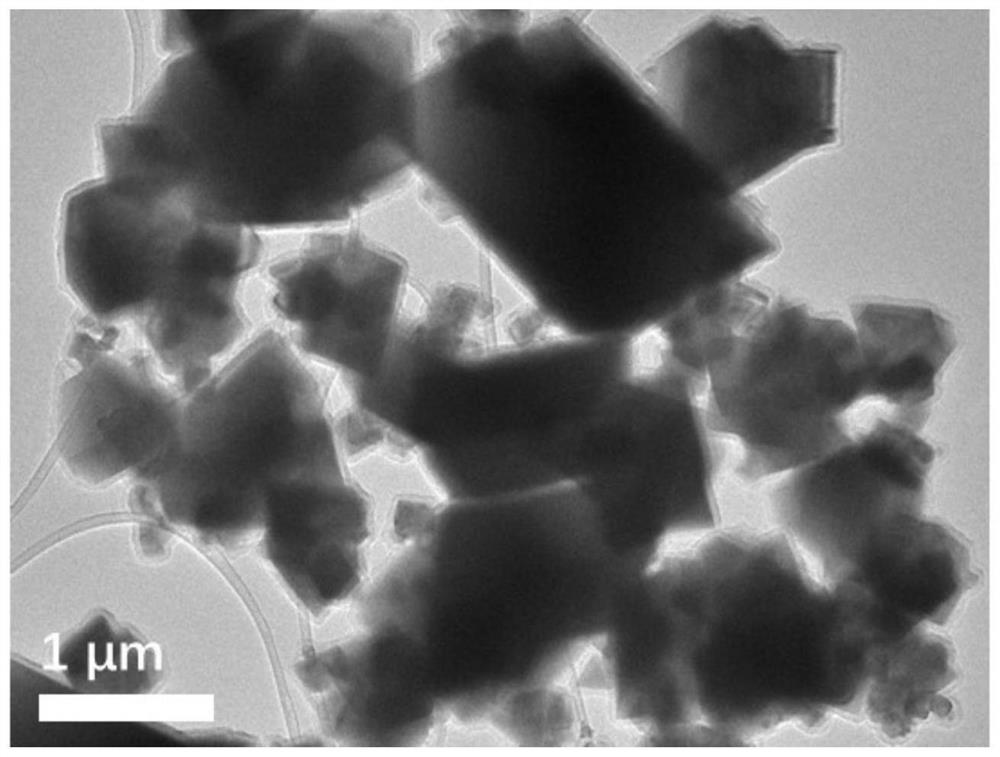

[0069] A hollow core-shell type antimony carbon composite negative electrode material, the preparation steps of which are basically the same as those in Example 1, the difference is that commercial antimony oxide nanoparticles are directly used in step (1).

[0070] A sodium ion battery, using the hollow core-shell type antimony carbon composite negative electrode material prepared in Example 2 as a negative electrode, the negative electrode material is matched with sodium metal, and assembled into a 2032 type button battery for performance testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com