A kind of cassava whole plant bio-fermentation feed and preparation method thereof

A bio-fermented feed and microbial fermentation technology, applied in the field of bio-fermented cassava whole plant bio-fermented feed and its preparation, to achieve the effects of easy access, improved immunity, and rich nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

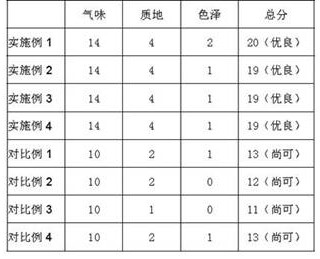

Examples

Embodiment 1

[0036] A method for preparing cassava whole plant bio-fermentation feed, comprising the following steps:

[0037](1) Cutting and crushing of raw materials: cutting cassava stalks and fresh cassava, cutting them to 2cm with a hay cutter, crushing pigeonpea stems and locust leaves, and passing through a 20-mesh sieve;

[0038] (2) High-temperature sterilization treatment: Put the cassava stalks that have been cut and treated in step (1) into a biodegradation tank, seal it and feed it with steam at a temperature of 120°C and a pressure of 25 MPa;

[0039] (3) Expansion cooling: the cassava stalks obtained after the steam treatment in step (2) are extruded and expanded by an extruder, and cooled to obtain dry granulation. After puffing, the drying temperature is 125°C, and the drying time is 25 minutes;

[0040] (4) Compound enzymes degrade cassava straw, fresh cassava, cassava stems and leaves, and black locust leaves:

[0041] S1 compound enzyme degrades pigeonpea stems and le...

Embodiment 2

[0047] A method for preparing cassava whole plant bio-fermentation feed, comprising the following steps:

[0048] (1) Cutting and crushing of raw materials: cutting cassava stalks and fresh cassava, cutting them to 5cm with a hay cutter, crushing pigeonpea stems and locust leaves, and passing through a 30-mesh sieve;

[0049] (2) High-temperature sterilization treatment: Put the cassava stalks that have been cut and treated in step (1) into a biodegradation tank, seal it and feed it with steam at a temperature of 120°C and a pressure of 25 MPa;

[0050] (3) Expansion cooling: the cassava stalks obtained after the steam treatment in step (2) are extruded and expanded by an extruder, and cooled to obtain dry granulation. After puffing, the drying temperature is 125°C, and the drying time is 25 minutes;

[0051] (4) Compound enzymes degrade cassava straw, fresh cassava, cassava stems and leaves, and black locust leaves:

[0052] S1 compound enzyme degrades pigeonpea stems and l...

Embodiment 3

[0058] A method for preparing cassava whole plant bio-fermentation feed, comprising the following steps:

[0059] (1) Cutting and crushing of raw materials: cutting cassava stalks and fresh cassava, cutting them to 5cm with a hay cutter, crushing pigeonpea stems and locust leaves, and passing through a 30-mesh sieve;

[0060] (2) High-temperature sterilization treatment: Put the cassava stalks that have been cut and treated in step (1) into a biodegradation tank, seal it and feed it with steam at a temperature of 150°C and a pressure of 55 MPa;

[0061] (3) Expansion cooling: the cassava stalks obtained after the steam treatment in step (2) are extruded and expanded by an extruder, and cooled to obtain dry granulation. After puffing, the drying temperature is 125°C, and the drying time is 25 minutes.

[0062] (4) Compound enzymes degrade cassava straw, fresh cassava, cassava stems and leaves, and black locust leaves:

[0063] S1 compound enzyme degrades pigeonpea stems and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com