Addition agent for maintaining activity of probiotics, compound probiotics and preparation method of compound probiotics

A technology of composite probiotics and additives, applied in the direction of bacteria, applications, and lactobacilli used in food preparation, can solve the problems of improving the activity of probiotics and rarely considering the protective effect of additives and probiotics, so as to promote proliferation and growth, Low cost, thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

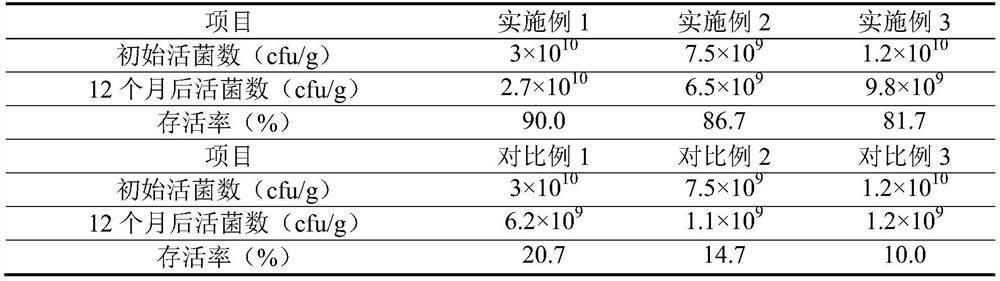

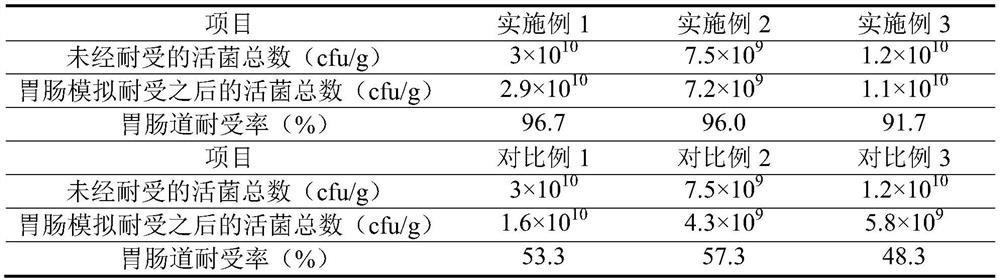

Embodiment 1

[0038] (1) The present invention is a combination of whey protein and inulin selected through a large number of experiments. The freeze-dried powder obtained by other combinations has poor dispersibility in water, or poor dispersibility in part. When brewing, it sinks to the bottom and is not easy to drink, and the powdery feeling will be more obvious. The preparation method of compound probiotics is described in detail below: additive for preparing polywhey protein-inulin freeze-dried powder: dissolving whey protein powder in water to form 6% (w / v specific unit such as g / 100mL×100%) whey protein solution; inulin was dissolved in water to form a 20% (w / v, supra) solution. Stir and heat the whey protein solution at 90°C for 20 minutes, add an appropriate amount of inulin solution to the heated polymerized whey protein solution in a hot state, so that the ratio of whey protein to inulin is 3:1, and the polymerized whey protein The protein-inulin solution continued to stir and h...

Embodiment 2

[0044] (1) Prepare polywhey protein-inulin freeze-dried powder: whey protein powder is dissolved in water to form 15% (w / v) whey protein solution; inulin is dissolved in water to form 20% (w / v) )The solution. Stir and heat the whey protein solution at 70°C for 10 minutes, add an appropriate amount of inulin solution to the heated polymerized whey protein solution in a hot state, so that the ratio of whey protein to inulin is 6:1, and the polymerized whey protein -Continue stirring and heating the inulin solution for 10 minutes, then cool to room temperature to obtain a weak gel. Freeze the weak gel at -60°C for 18 hours, then freeze-dry and crush at low temperature to a particle size of 0.1 mm to obtain the polywhey protein-inulin freeze-dried powder.

[0045] (2) According to parts by weight, take 5 parts of Bifidobacterium longum bacteria powder (the live bacteria content is 5×10 10 CFU / g), 5 parts of Lactobacillus acidophilus powder (the live bacteria content is 1×10 11 ...

Embodiment 3

[0050] (1) Prepare polywhey protein-inulin freeze-dried powder: whey protein powder is dissolved in water to form 10% (w / v) whey protein solution; inulin is dissolved in water to form 20% (w / v) )The solution. Stir and heat the whey protein solution at 80°C for 15 minutes, add an appropriate amount of inulin solution to the heated polymerized whey protein solution in a hot state, so that the ratio of whey protein to inulin is 4:1, and the polymerized whey protein -Continue stirring and heating the inulin solution for 15 minutes, then cool to room temperature to obtain a weak gel. Freeze the weak gel at -40°C for 24 hours, then freeze-dry and crush at low temperature to a particle size of 0.3 mm to obtain the polywhey protein-inulin freeze-dried powder.

[0051] (2) According to parts by weight, weigh Bifidobacterium animalis, Bifidobacterium adolescentis, Bifidobacterium infantis, Lactobacillus casei, Lactobacillus acidophilus, Lactobacillus rhamnosus compound lactic acid bact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com