Preparation method of antifogging coating solution for spectacle lenses

An anti-fog technology for spectacle lenses, which is applied in the fields of lens cleaning compositions, chemical instruments and methods, and other chemical processes, and can solve the problems of undiscovered anti-fog coating liquid for spectacle lenses and unsatisfied anti-fog needs of users, etc. problem, to achieve good lens anti-fog performance and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

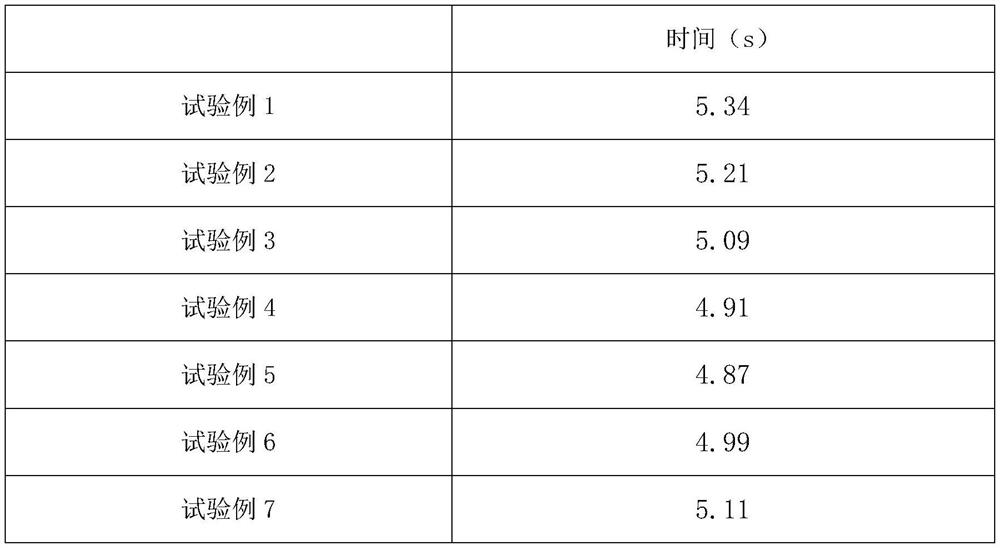

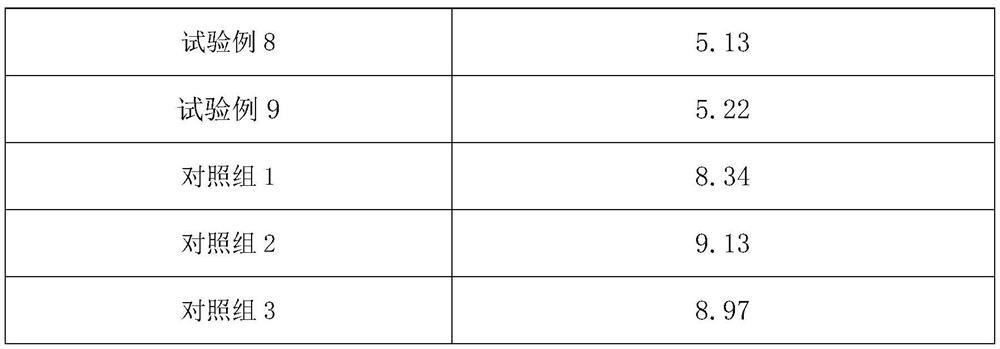

Examples

Embodiment 1

[0024] Prepare 15 parts of nonionic surfactants consisting of fatty alcohol polyoxyethylene ether, block polyoxyethylene-polyoxypropylene ether and alkanolamide with a mass ratio of 3:4:2 according to parts by weight. 60 parts of diluent composed of 2:4:5 butanol, xylene and butyl acetate, 10 parts of anionic surfactant composed of anionic polyacrylamide and fatty acid sodium with a mass ratio of 1:5, 5 parts of aloe extract 2 parts and 2 parts of sodium ascorbyl phosphate as raw materials, wherein the method of extracting the aloe extract is as follows: pick the aloe with no disease and no spots on the surface, wash, dry, peel, kill green, dry, crush and sieve to obtain Aloe vera powder, adding ethanol solution to the aloe vera powder for soaking, then using microwave radiation to extract, filtering to obtain the first extract, recovering the solvent, obtaining the first concentrated solution, and using the filter residue for later use; soaking the filter residue in a water-sa...

Embodiment 2

[0026] Prepare 16 parts of nonionic surfactants consisting of fatty alcohol polyoxyethylene ether, block polyoxyethylene-polyoxypropylene ether and alkanolamides with a mass ratio of 3:4:2 according to parts by weight. 62 parts of diluent composed of butanol, xylene and butyl acetate of 2:4:5, 12 parts of anionic surfactant composed of anionic polyacrylamide and fatty acid sodium with a mass ratio of 1:5, 6 parts of aloe extract 3 parts and 3 parts of sodium ascorbyl phosphate as raw materials, wherein the method of extracting the aloe extract is as follows: pick the aloe with no disease and spots on the surface, wash, dry, peel, kill green, dry, crush and sieve to obtain Aloe vera powder, adding ethanol solution to the aloe vera powder for soaking, then using microwave radiation to extract, filtering to obtain the first extract, recovering the solvent, obtaining the first concentrated solution, and using the filter residue for later use; soaking the filter residue in a water-s...

Embodiment 3

[0028] Prepare 18 parts of nonionic surfactants consisting of fatty alcohol polyoxyethylene ethers, block polyoxyethylene-polyoxypropylene ethers and alkylolamides with a mass ratio of 3:4:2 according to parts by weight. 65 parts of diluent composed of 2:4:5 butanol, xylene and butyl acetate, 13 parts of anionic surfactant composed of anionic polyacrylamide and fatty acid sodium with a mass ratio of 1:5, 7 parts of aloe extract 4 parts and 4 parts of sodium ascorbyl phosphate as raw materials, wherein the extraction method of aloe extract is as follows: pick aloe vera with no disease or spot on the surface, wash, dry, peel, kill green, dry, crush and sieve to obtain Aloe vera powder, adding ethanol solution to the aloe vera powder for soaking, then using microwave radiation to extract, filtering to obtain the first extract, recovering the solvent, obtaining the first concentrated solution, and using the filter residue for later use; soaking the filter residue in a water-saturat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com