Permeation method for improving coercive force of sintered neodymium iron boron

A neodymium-iron-boron, coercive force technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of low utilization rate of heavy rare earths, difficult to penetrate magnets, poor consistency of magnets, etc., to achieve the use of heavy rare earths The effect of reducing the amount of rare earth, continuous rare earth-rich phase at the grain boundary, and increasing the coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

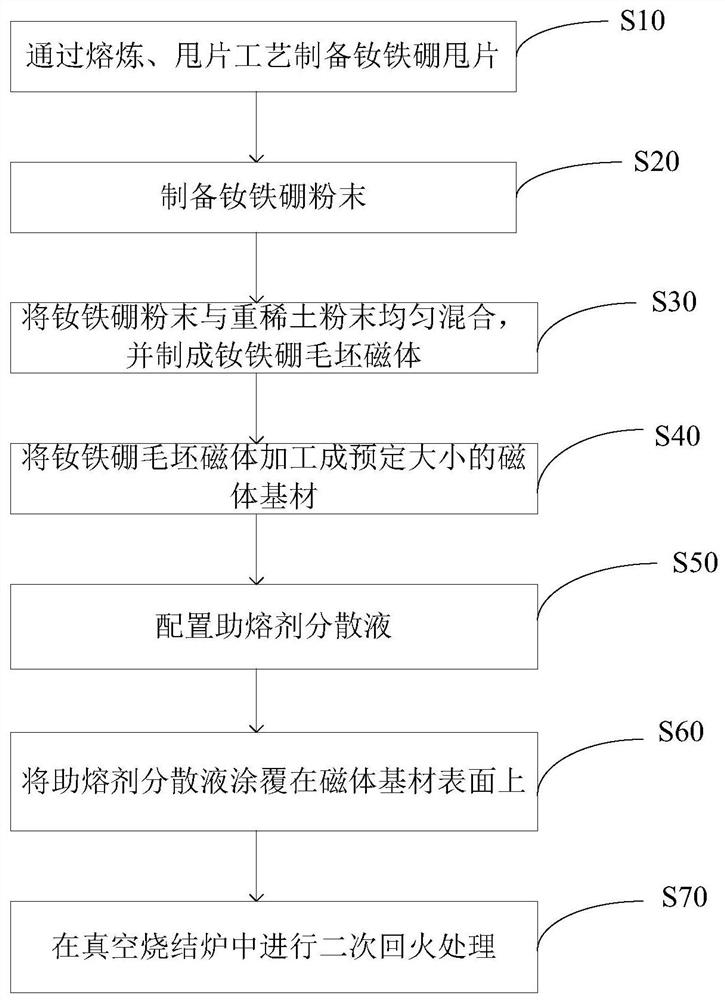

Method used

Image

Examples

Embodiment 1

[0053] Step 1. Select 42H neodymium iron boron as the base material, and cast the raw material into flakes;

[0054] Step 2, the flakes in step 1 are prepared into NdFeB powder by hydrogen crushing, intermediate crushing and jet milling, the average particle size of the powder is 3.2-33 μm, and then terbium fluoride powder with an average particle size of 0.5 μm is added to make Terbium fluoride powder: the weight ratio of NdFeB powder is 0.5wt%, mixed for 4 hours using a V-type powder mixer;

[0055] Step 3. The mixed powder is oriented and pressed in a magnetic field of 1.5T, and the compacted density after pressing is 3.8g / cm 3 , sintering the pressed blank at 1030°C for 5 hours under vacuum conditions to obtain a NdFeB blank;

[0056] Step 4, ultrasonically dispersing 100 g of boron oxide powder and 1 g of polyvinylpyrrolidone in ethanol, wherein the size of the boron oxide powder is 1.2 μm;

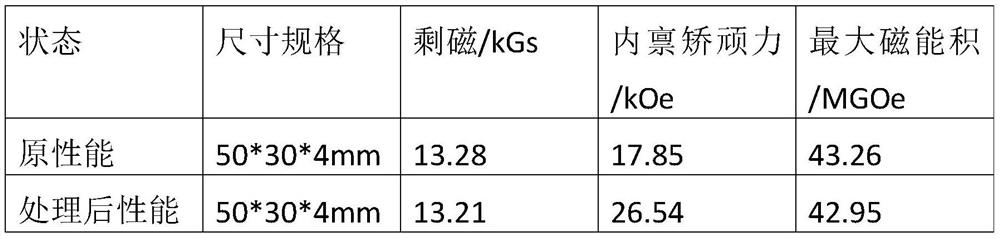

[0057] Step 5. Process the NdFeB blank into a 50*30*4mm magnet substrate, then...

Embodiment 2

[0063] Step 1. Select 42H neodymium iron boron as the base material, and cast the raw material into flakes;

[0064] Step 2, the flakes in step 1 are prepared into NdFeB powder by hydrogen crushing, medium crushing and jet milling, the average particle size of the powder is 3.2-33 μm, and then dysprosium fluoride powder with an average particle size of 0.5 μm is added to make Dysprosium fluoride powder: the weight ratio of neodymium iron boron powder is 0.5wt%, mixed for 4 hours using a V-type powder mixer;

[0065] Step 3. The mixed powder is oriented and pressed in a magnetic field of 1.5T, and the compacted density after pressing is 3.8g / cm 3 , sintering the pressed blank at 1030°C for 5 hours under vacuum conditions to obtain a NdFeB blank;

[0066] Step 4, ultrasonically dispersing 100 g of boron oxide powder and 1 g of polyvinylpyrrolidone in propanol, wherein the size of the boron oxide powder is 2 μm;

[0067] Step 5. Process the NdFeB blank into a 50*30*4mm magnet s...

Embodiment 3

[0073] Step 1. Select NdFeB with the brand name of 52H as the base material, and pour the raw material into flakes;

[0074] Step 2, the flakes in step 1 are prepared into NdFeB powder by hydrogen crushing, intermediate crushing and jet milling, the average particle size of the powder is 3.2-33 μm, and then terbium fluoride powder with an average particle size of 0.5 μm is added to make Terbium fluoride powder: the weight ratio of NdFeB powder is 0.5wt%, mixed for 4 hours using a V-type powder mixer;

[0075] Step 3. The mixed powder is oriented and pressed in a magnetic field of 1.5T, and the compacted density after pressing is 3.8g / cm 3 , sintering the pressed blank at 1070°C for 5 hours under vacuum conditions to obtain a NdFeB blank;

[0076] Step 4, ultrasonic dispersion of 100g of lithium carbonate powder and 1g of polyvinylpyrrolidone in ethanol, wherein the size of lithium carbonate powder is 1.2 μm;

[0077] Step 5. Process the NdFeB blank into a 50*30*4mm magnet su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com