Pre-wrapping powder, pre-wrapping powder paste, preparation method of deep-fried pre-wrapping powder and application of beta-glucan in reducing oil content

A technology for glucan and oil content, which is applied in the field of food processing and can solve the problems of unfavorable gluten formation, low gliadin content, and difficulty in molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In the embodiment of the present invention, β-glucan is extracted by water extraction, and the preparation method includes:

[0044](1) Raw material pretreatment: use absolute ethanol (bran powder: ethanol = 1:4 (g: mL)) to reflux at 80°C for 2 hours to inactivate the enzyme, and dry at 50°C for later use.

[0045] (2) Extraction of β-glucan:

[0046] 1. Sample weighing: take 30-40 parts by weight of the pretreated barley bran powder;

[0047] ②Add deionized water: add deionized water according to the ratio of material to water 1:15;

[0048] ③In addition to starch: after mixing, use 20% Na 2 CO 3 Adjust the pH to 10, add 4.5mL (about 135U) of high temperature resistant amylase, reflux extraction at 90°C±5°C for 2h, cool to room temperature and centrifuge (4500r / min, 15min) to collect the supernatant, and add Appropriate amount of high temperature-resistant amylase, keep at 85°C for 1-2h, choose 0.1mol / L iodine solution as indicator, until the iodine solution does n...

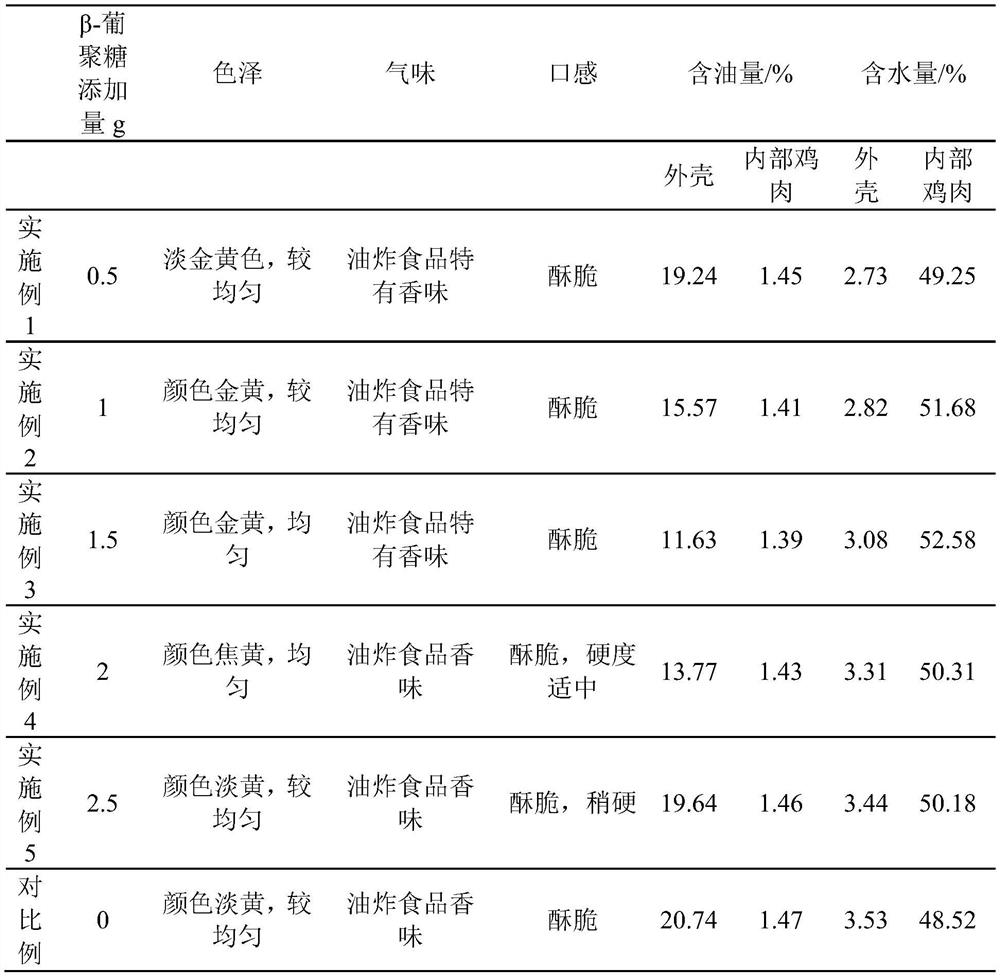

Embodiment 1

[0058] 1) First mix 59.5g of all-purpose flour, 40g of cornstarch, 1g of baking powder, 1g of salt, and then add 0.5g of the prepared β-glucan, and mix in a vortex mixer at 1500r / min for 10min to obtain the prepared Breaded.

[0059] 2) Cut 200g of fresh chicken breast into small pieces of uniform size of 2cm×2cm×2cm, marinate, season and set aside.

[0060] 3) Add 150g of water to the pre-coated powder mixed in step 1) to make a uniform and particle-free paste;

[0061] 4) Battering: Take the prepared chicken nuggets and put them into the evenly mixed batter for battering, then take out the chicken nuggets and drain for 10 seconds, repeat 2-3 times;

[0062] 5) Put the battered chicken nuggets into soybean oil with an oil temperature of 170-180°C and fry for 30-40s, take it out and cool for 3-5 minutes, wait for the oil temperature to rise to 190-200°C, and then fry for 20- 30s; after the frying is completed, take it out, drain the oil, dry it with hot air at 30-50°C for 30...

Embodiment 2

[0064] 1) First mix 59g of all-purpose flour, 40g of cornstarch, 1g of baking powder, 1g of salt, and then add 1g of the prepared β-glucan, and mix in a vortex mixer at 1500r / min for 10 minutes to obtain the pre-coated powder .

[0065] 2) Same as step 2) of Example 1.

[0066] 3) Same as embodiment 1 step 3).

[0067] 4) Same as step 4) of Example 1.

[0068] 5) Same as step 5) of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com