Wastewater treatment process for hydrogen peroxide production

A wastewater treatment, hydrogen peroxide technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem that the treatment effect is difficult to meet the sewage standard, difficult to remove CODcr and phosphate, water quality and quantity Instability and other problems, to achieve the effect of reducing CODcr and phosphate content, low cost, and lightening load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

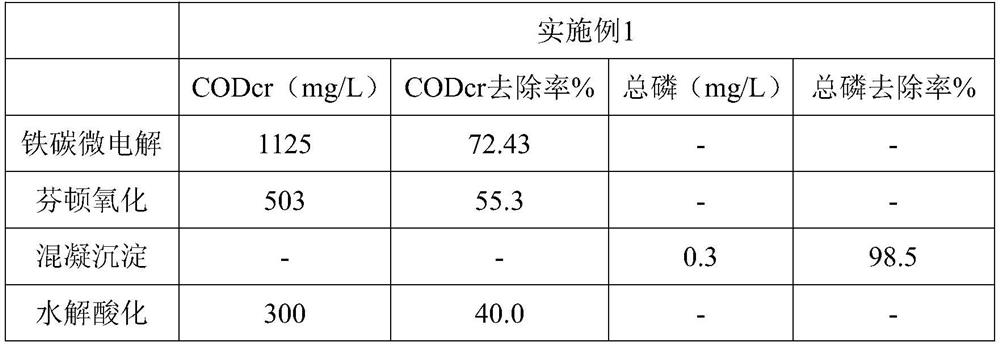

Embodiment 1

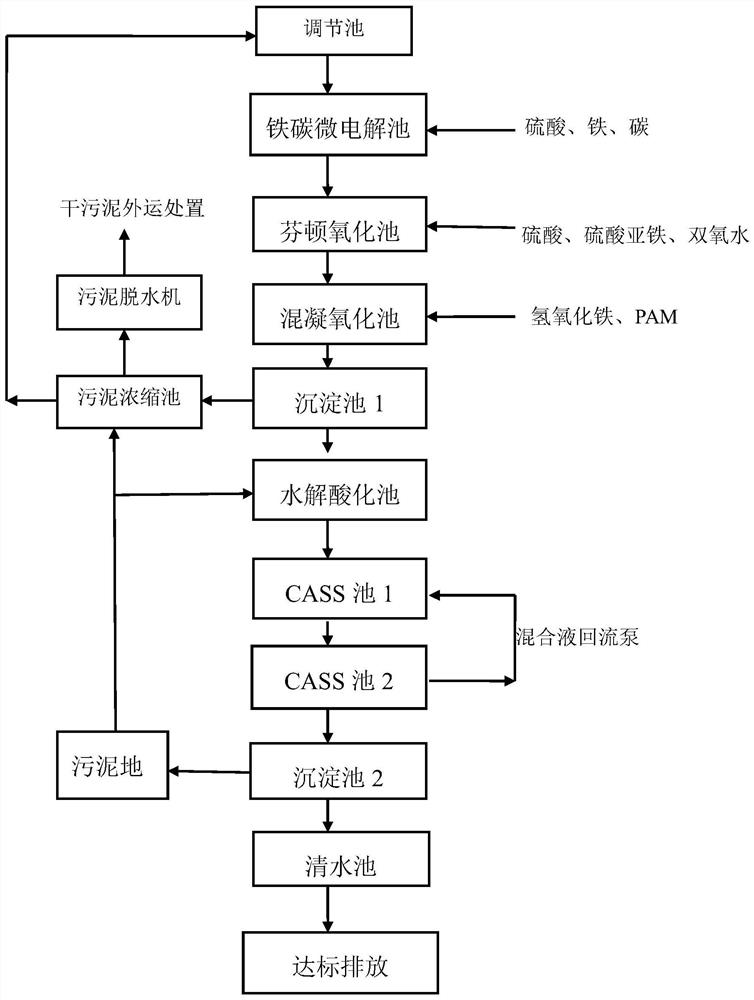

[0037] A wastewater treatment process for producing hydrogen peroxide, comprising the following process steps:

[0038] Step 1. Oxidation pretreatment: the wastewater is treated successively through the regulating tank, the iron-carbon micro-electrolytic tank, the Fenton oxidation tank, the coagulation oxidation tank and the sedimentation tank 1;

[0039] Step 2, biochemical treatment: the waste water flowing out of step 1 is treated successively through the hydrolytic acidification tank, the CASS tank and the sedimentation tank 2, and then discharged into the clean water tank;

[0040] Described oxidation pretreatment comprises the following steps:

[0041] (a) The wastewater is first adjusted to the same concentration of wastewater through the regulating tank;

[0042](b) The regulated wastewater enters the iron-carbon micro-electrolytic cell. In terms of per liter of wastewater, the dosage of iron powder is 9.5g, and the dosage of carbon powder is 2.0g, and then the pH val...

Embodiment 2

[0052] A wastewater treatment process for producing hydrogen peroxide, comprising the following process steps:

[0053] Step 1. Oxidation pretreatment: the wastewater is treated successively through the regulating tank, the iron-carbon micro-electrolytic tank, the Fenton oxidation tank, the coagulation oxidation tank and the sedimentation tank 1;

[0054] Step 2, biochemical treatment: the waste water flowing out of step 1 is treated successively through the hydrolytic acidification tank, the CASS tank and the sedimentation tank 2, and then discharged into the clean water tank;

[0055] Described oxidation pretreatment comprises the following steps:

[0056] (a) The wastewater is first adjusted to the same concentration of wastewater through the regulating tank;

[0057] (b) The regulated wastewater enters the iron-carbon micro-electrolytic cell. In terms of per liter of wastewater, the dosage of iron powder is 8.4g, and the dosage of carbon powder is 2.4g, and the pH value i...

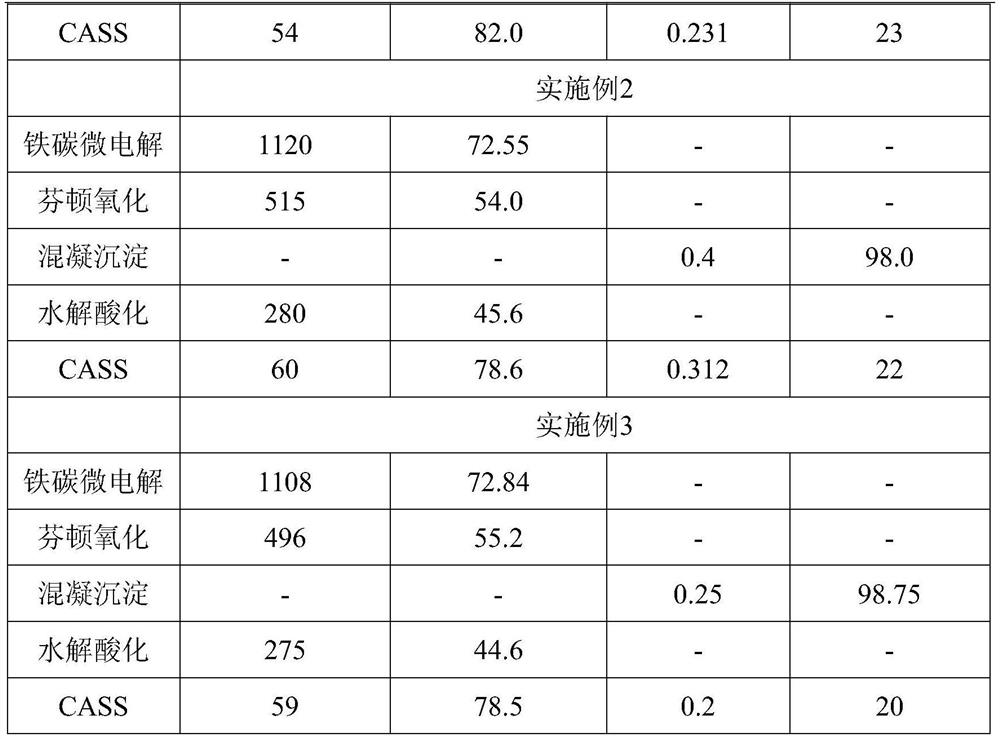

Embodiment 3

[0067] A wastewater treatment process for producing hydrogen peroxide, comprising the following process steps:

[0068] Step 1. Oxidation pretreatment: the wastewater is treated successively through the regulating tank, the iron-carbon micro-electrolytic tank, the Fenton oxidation tank, the coagulation oxidation tank and the sedimentation tank 1;

[0069] Step 2, biochemical treatment: the waste water flowing out of step 1 is treated successively through the hydrolytic acidification tank, the CASS tank and the sedimentation tank 2, and then discharged into the clean water tank;

[0070] Described oxidation pretreatment comprises the following steps:

[0071] (a) The wastewater is first adjusted to the same concentration of wastewater through the regulating tank;

[0072] (b) The adjusted waste water enters the iron-carbon micro-electrolytic cell. In terms of per liter of waste water, the dosage of iron powder is 11.2g, and the dosage of carbon powder is 1.2g, and then the pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com