A method for preparing arsenic-containing borosilicate glass by treating arsenic solid waste

A borosilicate glass and glass raw material technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as arsenic recovery, achieve the effects of reducing environmental impact, good heat resistance, and low arsenic precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

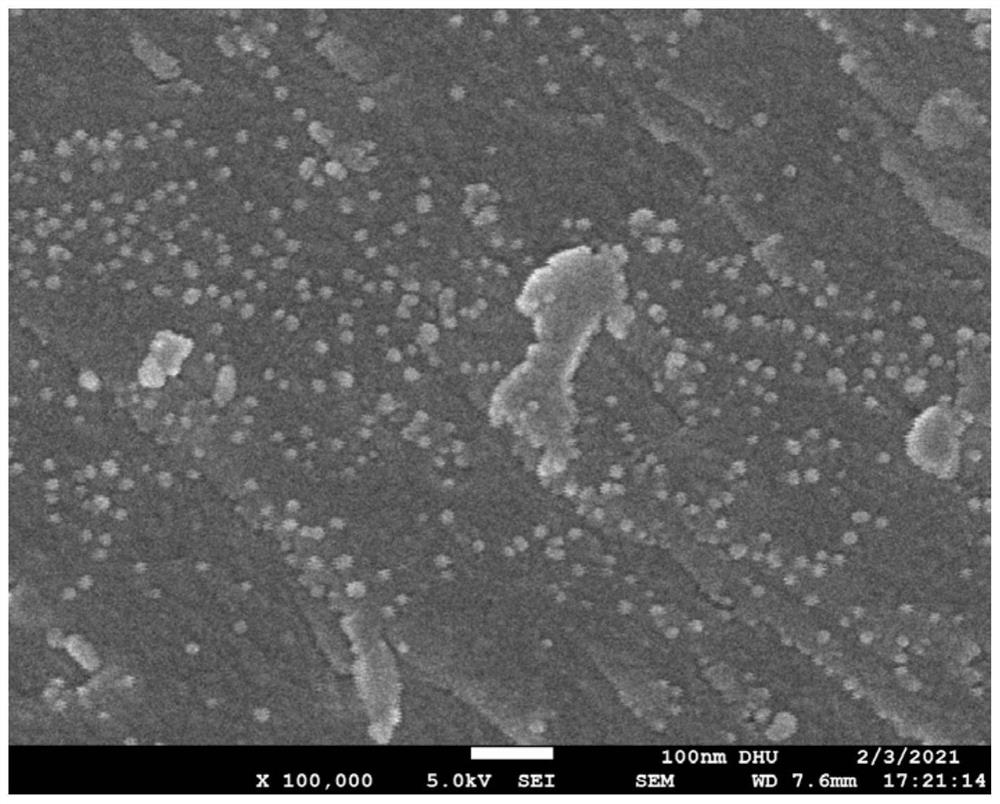

Image

Examples

Embodiment 1

[0041] A method for preparing arsenic-containing borosilicate glass by treating arsenic solid waste, comprising the steps of:

[0042] (1) Preparation of calcium arsenate and calcium arsenite:

[0043] S1: Alkaline leaching of arsenic-containing non-ferrous metal solid waste (arsenic content 7%) with a sodium hydroxide solution with a mass concentration of 5% at 25°C for 6 hours, and adding hydrogen peroxide with a concentration of 50% for oxidation treatment to obtain soaking liquid;

[0044] S2: Filter the soaking liquid to obtain the transition liquid and insoluble recyclable non-ferrous metal solid waste;

[0045] S3: Add saturated calcium hydroxide solution to the transition liquid, treat at 60°C for 6 hours, and filter to separate the precipitates of calcium arsenate and calcium arsenite and their mixture with sodium hydroxide, and then filter , and recover the precipitate and the sodium hydroxide filtrate.

[0046] The obtained precipitates are calcium arsenate and c...

Embodiment 2

[0050] A method for preparing arsenic-containing borosilicate glass by treating arsenic solid waste, comprising the steps of:

[0051] (1) Preparation of barium arsenate and barium arsenite:

[0052] S1: Alkaline leaching of arsenic-containing non-ferrous metal solid waste (arsenic content 11%) in a sodium hydroxide solution with a mass concentration of 6% at 35°C for 6 hours, and adding 35% hydrogen peroxide for oxidation treatment to obtain a soaking solution ;

[0053] S2: Filter the soaking liquid to obtain the transition liquid and insoluble recyclable non-ferrous metal solid waste;

[0054] S3: Add saturated barium hydroxide solution to the transition liquid, treat at 65°C for 6 hours, and filter to separate the precipitates of barium arsenate and barium arsenite and their mixed solution with sodium hydroxide, and then filter , and recover the precipitate and the sodium hydroxide filtrate.

[0055] The obtained precipitates are barium arsenate and barium arsenite, in ...

Embodiment 3

[0059] A method for preparing arsenic-containing borosilicate glass by treating arsenic solid waste, comprising the steps of:

[0060] (1) Preparation of calcium arsenate and calcium arsenite:

[0061] S1: Alkaline leaching of arsenic-containing non-ferrous metal solid waste (arsenic content 13%) with a sodium hydroxide solution with a mass concentration of 9% at 45°C for 3 hours, and adding 10% hydrogen peroxide for oxidation treatment to obtain a soaking solution ;

[0062] S2: Filter the soaking liquid to obtain the transition liquid and insoluble recyclable non-ferrous metal solid waste;

[0063] S3: Add saturated calcium hydroxide solution to the transition liquid, treat at 68°C for 3 hours, and filter to separate the precipitates of calcium arsenate and calcium arsenite and their mixture with sodium hydroxide, and then filter , and recover the precipitate and the sodium hydroxide filtrate.

[0064] The obtained precipitates are calcium arsenate and calcium arsenite, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com