Production process and production equipment of environment-friendly degradable plastic shopping bag

A technology for degrading plastics and production processes, applied to hollow objects, other household appliances, applications, etc., can solve the problems of mechanical properties of plastic processing characteristics that cannot meet daily use, slow decomposition of polyester, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

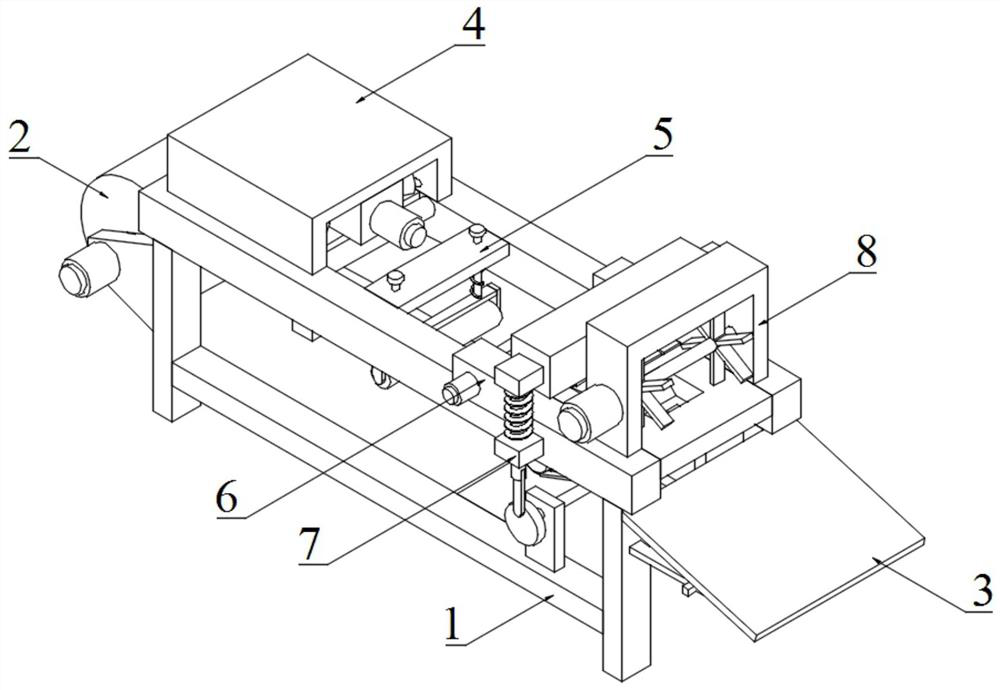

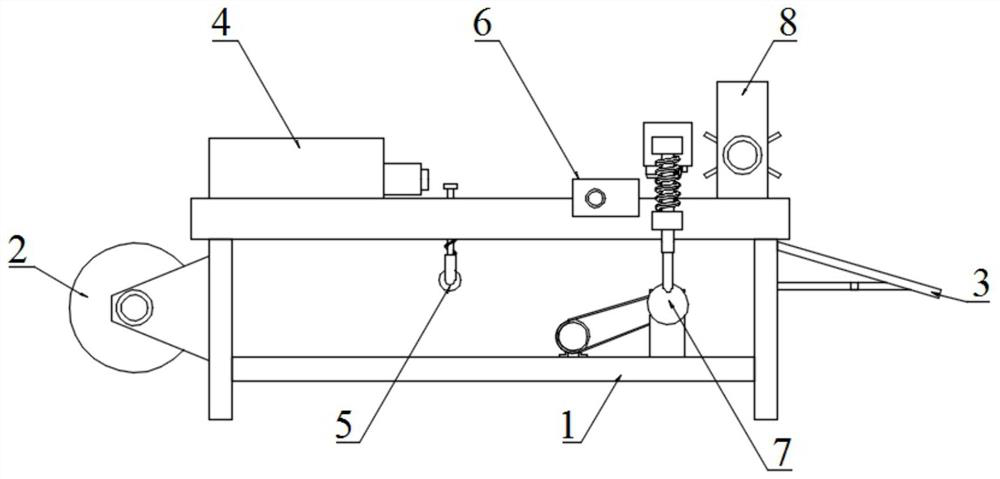

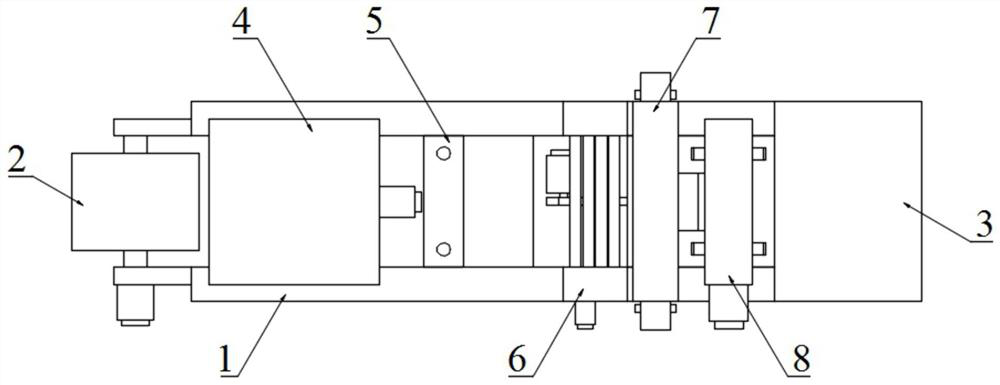

Image

Examples

Embodiment 1

[0047] A production process of an environment-friendly degradable plastic shopping bag, the degradable plastic shopping bag is made by mixing modified PE resin and modified PBAT resin at a mass ratio of 1:1, and the preparation method comprises the following steps:

[0048] S1. Preparation of lignin nanoparticles by acid hydrolysis, and then by modifying SiO 2 modifying the surface of lignin nanoparticles to obtain modified lignin nanoparticles;

[0049] S2. PBAT resin and modified lignin nanoparticles are added to a twin-screw extruder for melting and mixing, and then granulated to obtain modified PBAT resin particles;

[0050] S3, polyethylene micropowder, TiO 2 , Kaolin and oxidized polyethylene wax are mixed according to the mass ratio of 1:1:1:3, and extruded through a twin-screw extruder to obtain a photo-thermo-oxidative degradation masterbatch;

[0051] S4. Mix the degraded masterbatch and polyethylene in a mass ratio of 3:96, and extrude modified PE resin particles ...

Embodiment 2

[0058] A production process of an environment-friendly degradable plastic shopping bag, the degradable plastic shopping bag is made by mixing modified PE resin and modified PBAT resin at a mass ratio of 1:1, and the preparation method comprises the following steps:

[0059] S1. Preparation of lignin nanoparticles by acid hydrolysis, and then by modifying SiO 2 modifying the surface of lignin nanoparticles to obtain modified lignin nanoparticles;

[0060] S2. PBAT resin and modified lignin nanoparticles are added to a twin-screw extruder for melting and mixing, and then granulated to obtain modified PBAT resin particles;

[0061] S3, polyethylene micropowder, TiO 2 , Kaolin and oxidized polyethylene wax are mixed according to the mass ratio of 1:1:1:3, and extruded through a twin-screw extruder to obtain a photo-thermo-oxidative degradation masterbatch;

[0062] S4. Mix the degraded masterbatch and polyethylene in a mass ratio of 3:97, and extrude modified PE resin particles ...

Embodiment 3

[0069] A production process of an environment-friendly degradable plastic shopping bag. The degradable plastic shopping bag is made by mixing modified PE resin and modified PBAT resin at a mass ratio of 1:1.5. The preparation method comprises the following steps:

[0070] S1. Preparation of lignin nanoparticles by acid hydrolysis, and then by modifying SiO 2 modifying the surface of lignin nanoparticles to obtain modified lignin nanoparticles;

[0071] S2. PBAT resin and modified lignin nanoparticles are added to a twin-screw extruder for melting and mixing, and then granulated to obtain modified PBAT resin particles;

[0072] S3, polyethylene micropowder, TiO 2 , kaolin and oxidized polyethylene wax are mixed according to the mass ratio of 1:1:1:4, and extruded through a twin-screw extruder to obtain a photo-thermo-oxidative degradation masterbatch;

[0073] S4. Mix the degraded masterbatch and polyethylene in a mass ratio of 3:98, and extrude modified PE resin particles th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com