Organic/inorganic composition for consolidating quicksand and preparation method thereof

A composition and organic technology, applied in the directions of organic fertilizers, fertilizer mixtures, chemical instruments and methods, etc., can solve the problems of limited use range and toxic acrylamide, and achieve the effects of increasing viscosity, low viscosity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

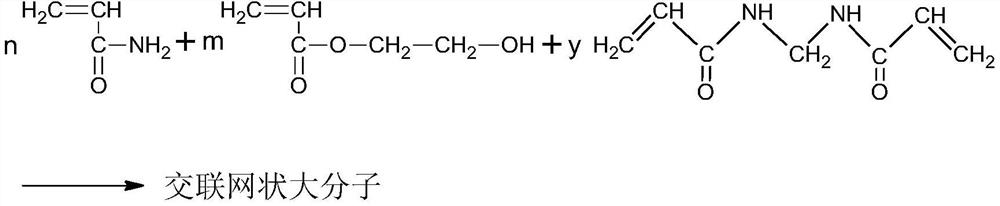

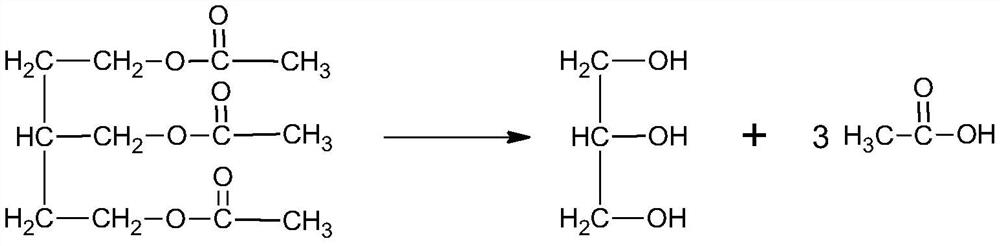

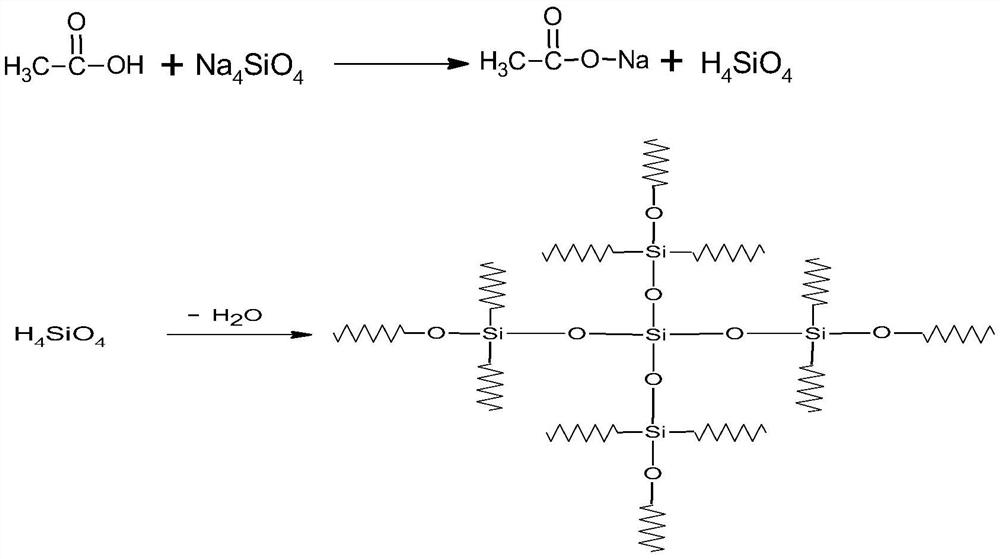

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of organic / inorganic composition that is used for consolidating quicksand described in this embodiment, comprises the component of following parts by weight:

[0038] Component A: 40 parts of hydroxyethyl acrylate, 30 parts of acrylamide, 2 parts of N,N-methylenebisacrylamide, 3 parts of triethanolamine, 5 parts of triacetin, and 20 parts of water;

[0039] Component B: 67 parts of water glass, 3 parts of initiator, 27 parts of water, and 3 parts of emulsifier.

[0040] The initiator described in this embodiment is ammonium persulfate.

[0041] The emulsifier described in this embodiment is the condensation product of O-10 fatty alcohol and ethylene oxide.

[0042] The water glass described in this embodiment has a modulus of 2.2 to 2.4 and a density of 1.4 to 1.5 g / cm 3 (20°C) sodium silicate water glass.

[0043] This embodiment is used for the preparation method of the organic / inorganic composition of consolidation quicksand, comprises the steps:

[0044] ...

Embodiment 2

[0050] A kind of organic / inorganic composition that is used for consolidating quicksand described in this embodiment, comprises the component of following parts by weight:

[0051] Component A: 41 parts of hydroxyethyl acrylate, 29 parts of acrylamide, 1.6 parts of N,N-methylenebisacrylamide, 2.4 parts of triethanolamine, 4 parts of triacetin, and 22 parts of water;

[0052] Component B: 69 parts of water glass, 3 parts of initiator, 25 parts of water, and 3 parts of emulsifier.

[0053] Initiator described in the present embodiment is potassium persulfate.

[0054] The emulsifier described in this embodiment is TX-13 alkylphenol polyoxyethylene ether.

[0055] The water glass described in this embodiment has a modulus of 2.2 to 2.4 and a density of 1.4 to 1.5 g / cm 3 (20°C) sodium silicate water glass.

[0056]This embodiment is used for the preparation method of the organic / inorganic composition of consolidation quicksand, comprises the steps:

[0057] The first step, the...

Embodiment 3

[0063] A kind of organic / inorganic composition that is used for consolidating quicksand described in this embodiment, comprises the component of following parts by weight:

[0064] Component A: 43 parts of hydroxyethyl acrylate, 28 parts of acrylamide, 1.4 parts of N,N-methylenebisacrylamide, 2 parts of triethanolamine, 2.6 parts of triacetin, and 23 parts of water;

[0065] Component B: 72 parts of water glass, 2 parts of initiator, 24 parts of water, and 2 parts of emulsifier.

[0066] The initiator described in this embodiment is ammonium persulfate.

[0067] The emulsifier described in this embodiment is the condensation product of O-10 fatty alcohol and ethylene oxide.

[0068] The water glass described in this embodiment has a modulus of 2.2 to 2.4 and a density of 1.4 to 1.5 g / cm 3 (20°C) sodium silicate water glass.

[0069] This embodiment is used for the preparation method of the organic / inorganic composition of consolidation quicksand, comprises the steps:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com