A heat treatment method and forming method of beryllium-free high-strength copper alloy parts

A heat treatment method, copper alloy technology, applied in the direction of additive manufacturing, additive processing, etc., can solve the problem of low yield strength, and achieve the effect of high fine powder yield, extremely oxygen content, and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

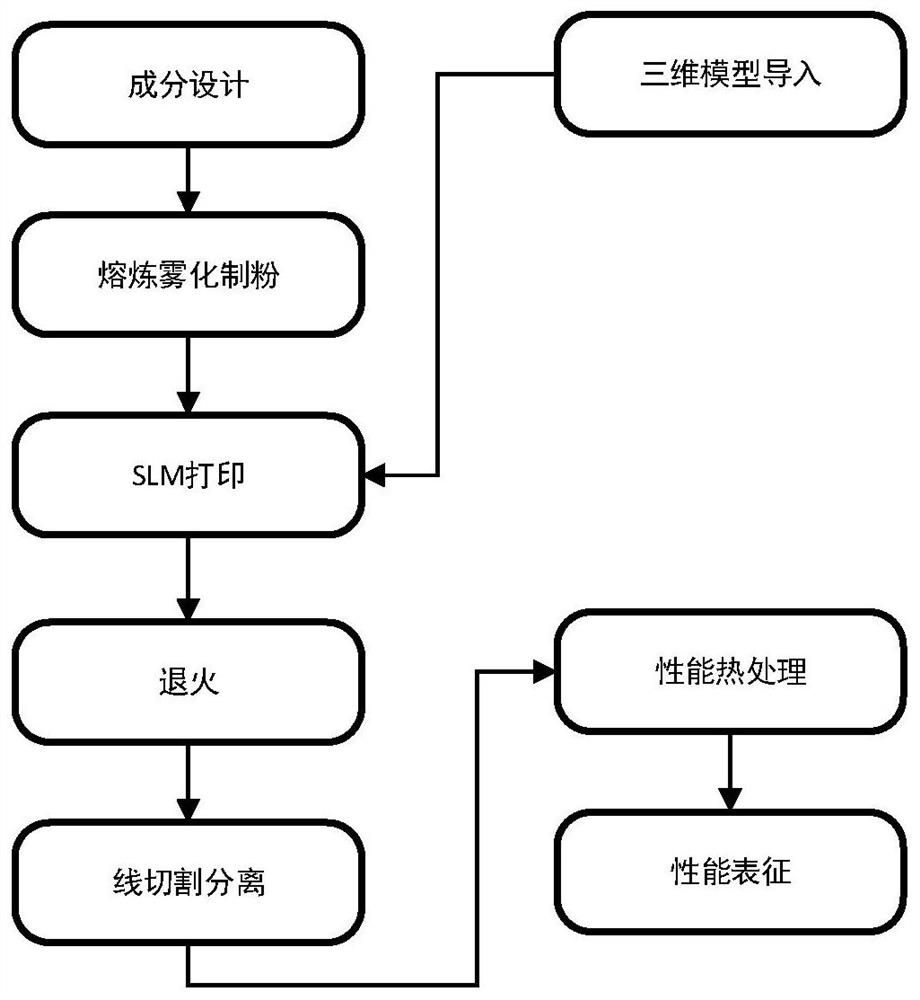

Image

Examples

Embodiment 1

[0051] 1. This embodiment provides a beryllium-free high-strength copper alloy, the composition of which is specifically: 24% Ni, 5% Sn, 2% Al, 1% Co, 0.5% Nb, 0.05% Ti, 0.75% V, 0.005% B, the balance is Cu.

[0052] 2, the copper alloy preparation process of the present embodiment is as follows:

[0053] Weigh the alloy element raw materials according to the above chemical composition ratio, put them into the melting crucible of the vacuum induction melting powder making furnace for vacuum melting, and obtain the copper alloy melt; use the infrared thermometer to measure the temperature of the melt, and heat the copper alloy liquid After reaching 1200-1300°C, heat-preserve and refine for 20-40 minutes; then fill the vacuum induction smelting powder-making furnace with 99.999% high-purity argon gas. The nozzle is impacted by the high-pressure and high-speed argon gas flow and broken into fine droplets, which are spheroidized while cooling and solidifying, and finally form sph...

Embodiment 2

[0068] 1. This embodiment provides a beryllium-free high-strength copper alloy, which is specifically composed by mass percentage: 20% Ni, 7% Sn, 1.5% Al, 0.5% Co, 0.2% Nb, 0.05% Ti, 0.6% V , 0.005% B, the balance is Cu.

[0069] 2, the copper alloy preparation process of the present embodiment is as follows:

[0070] Weigh the alloy element raw materials according to the above chemical composition ratio, put them into the melting crucible of the vacuum induction melting powder making furnace for vacuum melting, and obtain the copper alloy melt; use the infrared thermometer to measure the temperature of the melt, and heat the molten steel to 1200~1300℃, heat preservation and refining for 20~40min; then fill the vacuum induction smelting powder making furnace with 99.999% high-purity argon. It is crushed into fine droplets by the impact of high-pressure and high-speed argon gas flow, and spheroidizes while cooling and solidifying, and finally forms spherical metal powder.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com