Environment-friendly aluminum profile spraying pretreatment process

A green and environmentally friendly aluminum profile technology, applied in the field of aluminum alloy processing, can solve the problems of easy pollution of environmental water resources, high treatment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

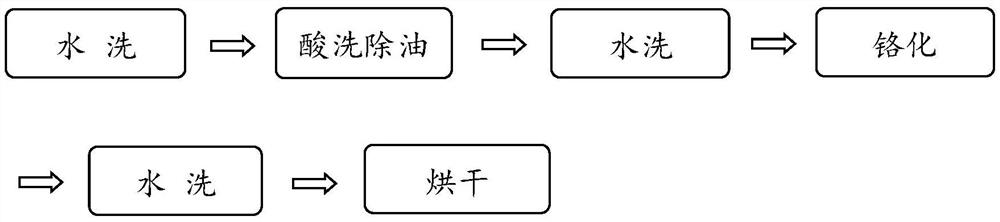

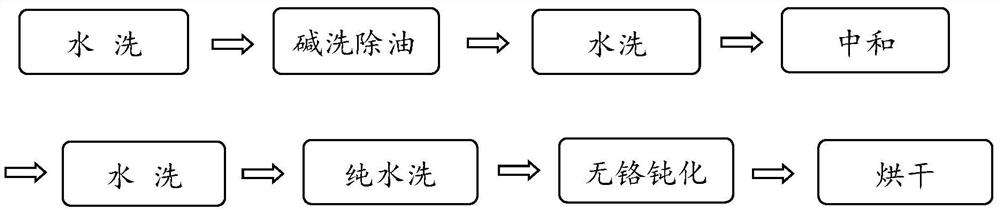

Method used

Image

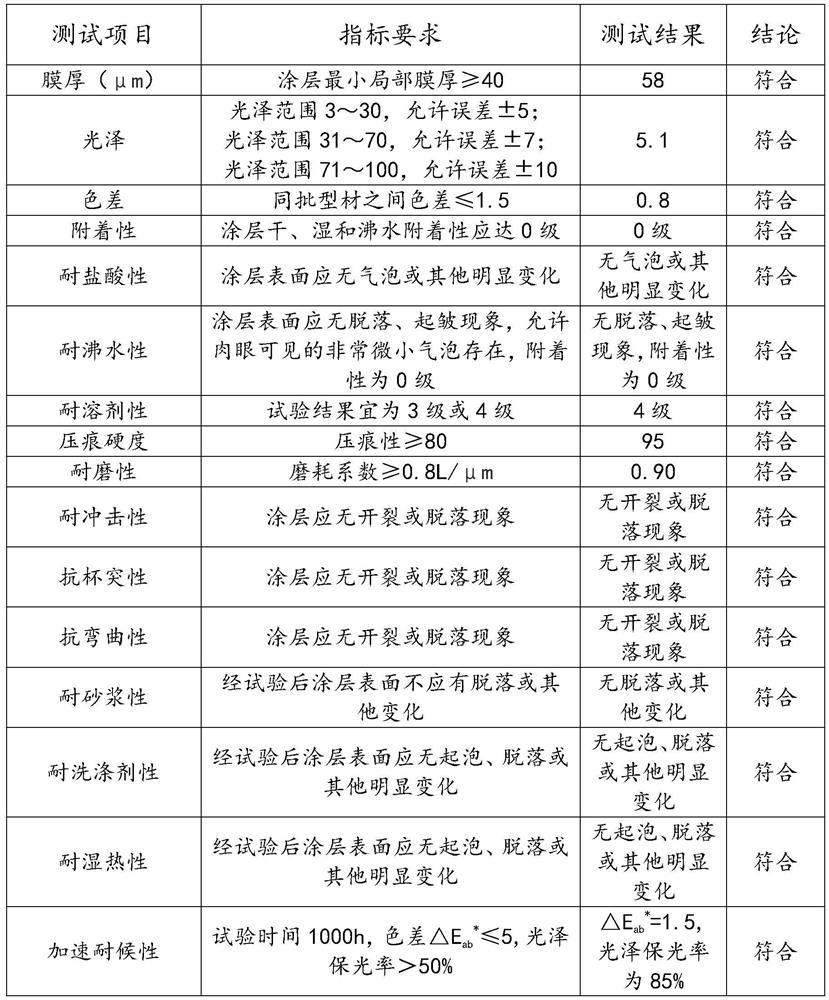

Examples

Embodiment 1

[0038] A kind of green environmental protection aluminum profile spraying pre-treatment process, the aluminum profile top hangs on the continuous conveying system, carries out various spraying pre-treatments in the conveying process, specifically comprises the following steps:

[0039] (1) Washing:

[0040] Clean the aluminum profile with tap water to remove dust and debris;

[0041] (2) Alkaline washing and degreasing:

[0042] Dissolve the degreasing agent in water to make a degreasing liquid, the concentration of the degreasing liquid is 1.5%, and spray the aluminum profile to remove oil. The degreasing agent includes the following components in parts by weight: 15 parts of sodium hydroxide, 8 parts of potassium, 1 part of aluminum hydroxide, 5 parts of sodium gluconate, 5 parts of sodium nitrite, 0.1 part of sodium thiosulfate;

[0043] The degreasing liquid is recycled, and the ion concentration of the degreasing liquid is monitored and controlled within the following r...

Embodiment 2

[0061] A kind of green environmental protection aluminum profile spraying pre-treatment process, the aluminum profile top hangs on the continuous conveying system, carries out various spraying pre-treatments in the conveying process, specifically comprises the following steps:

[0062] (1) Washing:

[0063] Clean the aluminum profile with tap water to remove dust and debris;

[0064] (2) Alkaline washing and degreasing:

[0065] Dissolve the degreasing agent in water to form a degreasing liquid, the concentration of the degreasing liquid is 1.8%, and spray the aluminum profile to remove oil. The degreasing agent includes the following components in parts by weight: 18 parts of sodium hydroxide, 10 parts of potassium, 1.5 parts of aluminum hydroxide, 4 parts of sodium gluconate, 4 parts of nitrous acid, 0.2 parts of sodium thiosulfate;

[0066] The degreasing liquid is recycled, and the ion concentration of the degreasing liquid is monitored and controlled within the followin...

Embodiment 3

[0084] A kind of green environmental protection aluminum profile spraying pre-treatment process, the aluminum profile top hangs on the continuous conveying system, carries out various spraying pre-treatments in the conveying process, specifically comprises the following steps:

[0085] (1) Washing:

[0086] Clean the aluminum profile with tap water to remove dust and debris;

[0087] (2) Alkaline washing and degreasing:

[0088] Dissolve the degreasing agent in water to form a degreasing liquid, the concentration of the degreasing liquid is 2%, and spray the aluminum profile to remove oil. The degreasing agent includes the following components in parts by weight: 20 parts of sodium hydroxide, 5 parts of potassium, 2 parts of aluminum hydroxide, 6 parts of sodium gluconate, 3 parts of sodium nitrite, 0.3 parts of sodium thiosulfate;

[0089] The degreasing liquid is recycled, and the ion concentration of the degreasing liquid is monitored and controlled within the following r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com