High-temperature-resistant aluminum alloy ceramic membrane

A technology of ceramic film and aluminum alloy, applied in the field of aluminum alloy surface, can solve the problems of poor impact resistance, poor thermal stability, large thermal deformation, etc., to prevent the diffusion of oxygen, improve high temperature oxidation resistance, and improve thermal shock resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. The sample is made of aluminum alloy plate, cut into 25mm×20mm×2mm, and holes are punched on the edge of the sample for connecting wires;

[0021] 2. Use sandpaper to polish the surface of the sample to 1200#, put it into an ultrasonic cleaner, clean it with absolute ethanol, and dry it for later use;

[0022] 3. Electrolyte adopts silicate system, sodium silicate nonahydrate 10gˑL -1 ,Potassium hydroxide 3gˑL -1 ; Additive CeO 2 5gˑL -1 ;

[0023] 4. Use bi-directional pulse power supply, adopt constant voltage mode, positive voltage is 300V, negative voltage is 70V, positive pulse width is 1000μs, negative pulse width is 1000μs, pulse interval is 300μs, oxidation time is 15min. Wash with ionized water and absolute ethanol, and blow dry;

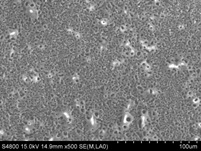

[0024] 5. Put it into a box-type resistance furnace, set the temperature at 400°C, hold for 10 hours, and observe the appearance as figure 1 .

Embodiment 2

[0026] 1. The sample is made of aluminum alloy plate, cut into 25mm×20mm×2mm, and holes are punched on the edge of the sample for connecting wires;

[0027] 2. Use sandpaper to polish the surface of the sample to 1200#, put it into an ultrasonic cleaner, clean it with absolute ethanol, and dry it for later use;

[0028] 3. Electrolyte adopts silicate system, sodium silicate nonahydrate 15gˑL -1 ,Potassium hydroxide 5gˑL -1 ; Additive CeO 2 4gˑL -1 ;

[0029] 4. Use bi-directional pulse power supply, adopt constant voltage mode, positive voltage is 300V, negative voltage is 80V, positive pulse width is 1000μs, negative pulse width is 1000μs, pulse interval is 300μs, oxidation time is 15min. Wash with ionized water and absolute ethanol, and blow dry;

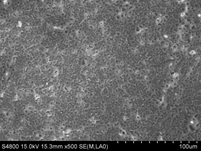

[0030] 5. Put it into a box-type resistance furnace, set the temperature at 450°C, hold for 10 hours, and observe the appearance as figure 2 .

Embodiment 3

[0032] 1. The sample is made of aluminum alloy plate, cut into 25mm×20mm×2mm, and holes are punched on the edge of the sample for connecting wires;

[0033] 2. Use sandpaper to polish the surface of the sample to 1200#, put it into an ultrasonic cleaner, clean it with absolute ethanol, and dry it for later use;

[0034] 3. Electrolyte adopts silicate system, sodium silicate nonahydrate 20gˑL -1 , Potassium hydroxide 7gˑL -1 ; Additive CeO 2 3gˑL -1 ;

[0035] 4. Use bi-directional pulse power supply, adopt constant voltage mode, positive voltage is 300V, negative voltage is 80V, positive pulse width is 1000μs, negative pulse width is 1000μs, pulse interval is 300μs, oxidation time is 15min. Wash with ionized water and absolute ethanol, and blow dry;

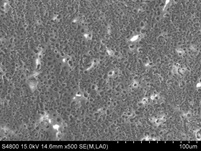

[0036] 5. Put it into a box-type resistance furnace, set the temperature at 500°C, and hold it for 10 hours. Observe the appearance as image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com