Graphene oxide enhanced photosensitive cover film composition

A technology for covering films and compositions, applied in the directions of optics, opto-mechanical equipment, and photosensitive materials for opto-mechanical equipment, etc., can solve the problems of decreased covering power, limited application, and limited improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

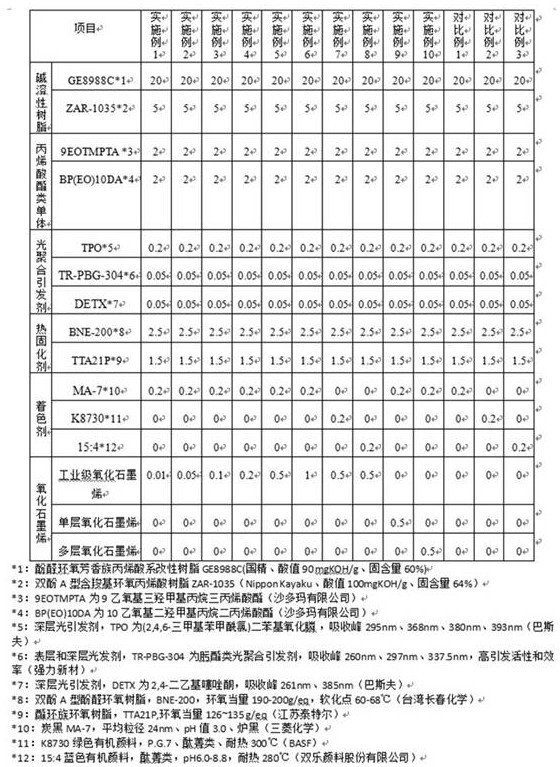

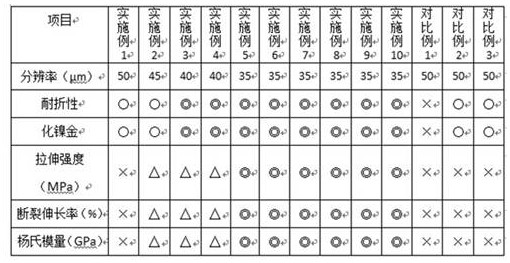

Embodiment 1

[0034] A graphene oxide enhanced photosensitive cover film composition, which is formed by mixing and curing the following raw materials: 20g alkali-soluble photosensitive epoxy acrylic resin GE8988C (acid value 90mgKOH / g, solid content 60%), 5g alkali-soluble photosensitive epoxy acrylic resin Resin ZAR-1035 (acid value 100mgKOH / g, solid content 64%), 4g acrylate monomer (including 2.0g 9EOTMPTA, 2.0g BP(EO)10DA), 0.3g photopolymerization initiator (including 0.05g TR-PBG -304, 0.2g TPO, 0.05gDETX), 4g thermal curing agent (including 2.5g BNE-200 epoxy resin, 1.5g TTA21P epoxy resin), 0.01g boron trifluoride ethylamine latent curing accelerator, 0.2g carbon Black MA-7, 0.01g industrial grade graphene oxide, 2.0g light diffusing agent EP-2601, 0.6g other additives (including 0.3g dispersant BYK168, 0.1g leveling agent BYK 394, 0.1g defoamer BYK354, 0.1g adhesion promoter ADP-S478). When preparing the graphene oxide-enhanced photosensitive cover film composition, the above-men...

Embodiment 2

[0036] A graphene oxide enhanced photosensitive cover film composition, which is formed by mixing and curing the following raw materials: 20g alkali-soluble photosensitive epoxy acrylic resin GE8988C (acid value 90mg KOH / g, solid content 60%), 5g alkali-soluble photosensitive epoxy Acrylic resin ZAR-1035 (acid value 100mg KOH / g, solid content 64%), 4g acrylate monomer (of which 2.0g 9EOTMPTA, 2.0gBP(EO)10DA), 0.3g photopolymerization initiator (of which 0.05g TR- PBG-304, 0.2g TPO, 0.05gDETX), 4g thermal curing agent (including 2.5g BNE-200 epoxy resin, 1.5g TTA21P epoxy resin), 0.01g boron trifluoride ethylamine latent curing accelerator, 0.2g Carbon black MA-7, 0.05g industrial grade graphene oxide, 2.0g light diffusing agent EP-2601, 0.6g other additives (including 0.3g dispersant BYK168, 0.1g leveling agent BYK 394, 0.1g defoamer BYK354 , 0.1g adhesion promoter ADP-S478). When preparing the graphene oxide-enhanced photosensitive cover film composition, the above-mentioned...

Embodiment 3

[0038] A graphene oxide enhanced photosensitive cover film composition, which is formed by mixing and curing the following raw materials: 20g alkali-soluble photosensitive epoxy acrylic resin GE8988C (acid value 90mgKOH / g, solid content 60%), 5g alkali-soluble photosensitive epoxy acrylic resin Resin ZAR-1035 (acid value 100mgKOH / g, solid content 64%), 4g acrylate monomer (including 2.0g 9EOTMPTA, 2.0g BP(EO)10DA), 0.3g photopolymerization initiator (including 0.05g TR-PBG -304, 0.2g TPO, 0.05gDETX), 4g thermal curing agent (including 2.5g BNE-200 epoxy resin, 1.5g TTA21P epoxy resin), 0.01g boron trifluoride ethylamine latent curing accelerator, 0.2g carbon Black MA-7, 0.1g industrial grade graphene oxide, 2.0g light diffusing agent EP-2601, 0.6g other additives (including 0.3g dispersant BYK168, 0.1g leveling agent BYK 394, 0.1g defoamer BYK354, 0.1g adhesion promoter ADP-S478). When preparing the graphene oxide-enhanced photosensitive cover film composition, the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com