Agilawood tea cake slice and preparation method thereof

The technology of agarwood tea and cake slices is applied in the direction of tea treatment before extraction, which can solve the problems of unfavorable quality stability, low aroma, weak taste, etc., and achieve the effects of ensuring quality stability, strong taste, and improving catalytic ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

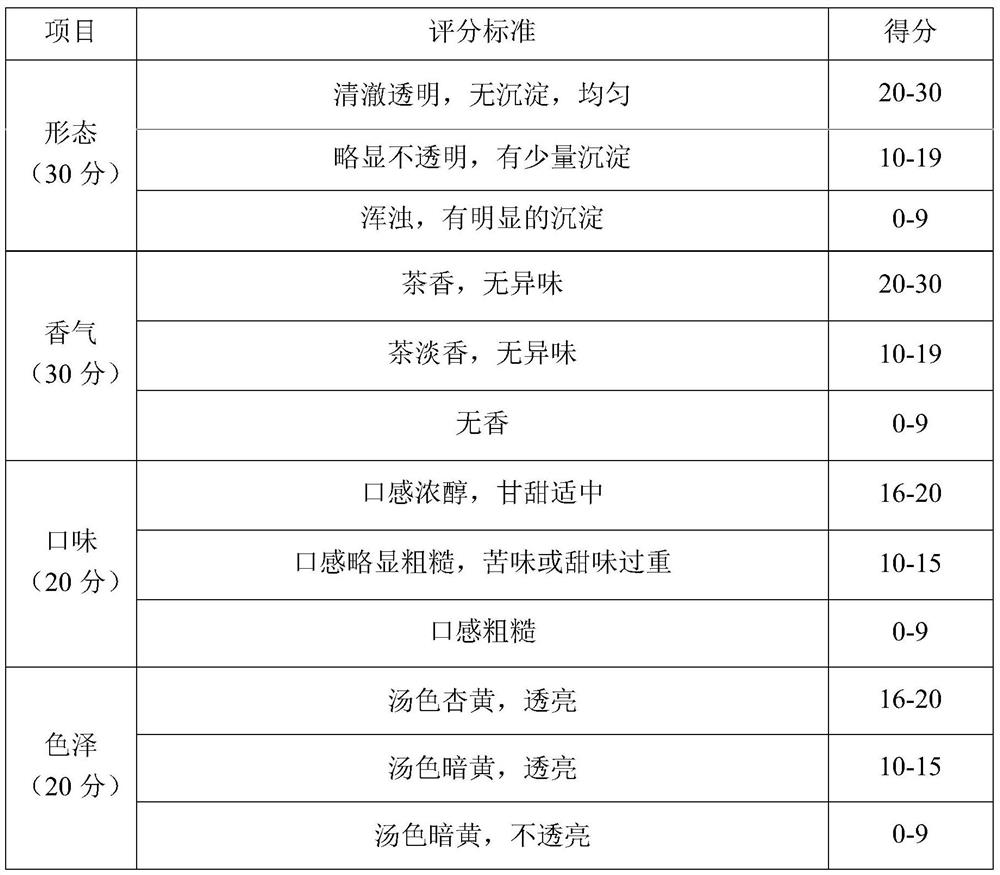

Image

Examples

Embodiment 1

[0022] A piece of agarwood tea cake: comprising the following raw materials in parts by weight: 12 parts of agarwood extract, 3 parts of tea tree mushroom extract, 1 part of hickory chick extract, and 20 parts of black tea leaves.

[0023] The agarwood extract is soaked in a compound phosphate solution, the volume ratio of the solid to liquid is 1:3, taken out and dried, crushed to 80 mesh, using ethanol as a solvent, adjusting the extraction temperature to 40°C, and ultrasonically Extract for 1 hour, then repeat the extraction once, combine the filtrates, and filter to obtain the agarwood extract;

[0024] The tea tree mushroom extract is washed with deionized water, placed in a ventilated place to dry the surface moisture naturally, crushed, put into a flask, add ethyl acetate, ultrasonically treat at 100W, 30kHz for 10min, collect volatile oil, and obtain tea tree mushroom extract;

[0025] The hickory chick extract is made by processing the hickory chick into filaments, m...

Embodiment 2

[0027] A piece of agarwood tea cake: comprising the following raw materials in parts by weight: 20 parts of agarwood extract, 5 parts of tea tree mushroom extract, 5 parts of hickory chick extract, and 60 parts of Pu'er tea;

[0028] The agarwood extract is soaked in agarwood compound phosphate solution, the volume ratio of solid to liquid is 1:6, taken out and dried, crushed to 120 mesh, using ethanol as solvent, adjusting the extraction temperature to 60°C, and ultrasonically Extract for 8 hours, then repeat the extraction 3 times, combine the filtrates, and filter to obtain the extract of Agarwood;

[0029] The tea tree mushroom extract is washed with deionized water, placed in a ventilated place to dry the surface moisture naturally, crushed, put into a flask, add ethyl acetate, ultrasonically treat for 30min at 200W, 50kHz, collect volatile oil, and obtain tea tree mushroom extract;

[0030] The hickory chick extract is made by processing the hickory chick into filaments...

Embodiment 3

[0032] A piece of agarwood tea cake, comprising the following raw materials in parts by weight: 16 parts of agarwood extract, 4 parts of tea tree mushroom extract, 3 parts of morel extract, and 40 parts of agarwood leaves;

[0033] The agarwood extract is soaked in agarwood compound phosphate solution, the volume ratio of solid to liquid is 1:5, taken out and dried, crushed to 100 mesh, using ethanol as a solvent, adjusting the extraction temperature to 50°C, and ultrasonically Extract for 5 hours, then repeat the extraction twice, combine the filtrates, and filter to obtain the extract of Agarwood;

[0034] The tea tree mushroom extract is washed with deionized water, placed in a ventilated place to dry the surface moisture naturally, crushed, put into a flask, add ethyl acetate, ultrasonically treat at 150W, 40kHz for 20min, collect volatile oil, and obtain tea tree mushroom extract mushroom extract;

[0035] The hickory chick extract is made by processing the hickory chick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com