Preparation method and application of alpha-alumina with reduced phase transition temperature

A phase transition temperature and alumina technology, applied in the field of sintered body materials, can solve problems such as complex operation, incomplete removal of solvents and additives, and reduced compactness of α-alumina, and achieve high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The first aspect of the present invention provides a method for preparing α-alumina with a reduced phase transition temperature, comprising:

[0031] Mix aluminum isopropoxide with a solvent, add ammonium bicarbonate solution to hydrolyze, dry, heat up the dried product, keep it warm, and cool down to obtain the product.

[0032] In one or more embodiments of the present invention, the solvent is selected from ethanol, propanol, n-butanol and isopropanol;

[0033] Further preferably, the solvent is isopropanol. Because the hydrolysis of aluminum isopropoxide will generate isopropanol and AlOOH, it is selected to dissolve aluminum isopropoxide in isopropanol for hydrolysis, which is beneficial to the uniformity of the hydrolysis process and avoids unhydrolyzed aluminum isopropoxide during the hydrolysis process. Being wrapped by hydrolyzed products affects the completeness of hydrolysis. On the other hand, the hydrolysis of aluminum isopropoxide will not introduce unne...

Embodiment 1

[0062] Under magnetic stirring, 5g of aluminum isopropoxide was added to 20mL of isopropanol, stirred at 70°C for 40min until aluminum isopropoxide was completely dissolved, then 15mL of water with a volume ratio of 1:4 was added dropwise. Isopropanol mixed solution, the hydrolysis temperature is 70°C, the hydrolysis time is 2h, the hydrolysis process is continuously stirred, after the hydrolysis is completed, the stirring is continued for 0.5h, the hydrolyzed gel is dried in a 60°C oven for 24h, and then the obtained The samples were heat-treated in a muffle furnace under the following conditions: the furnace temperature was raised to 1150°C within 2 hours, kept at 1150°C for 2 hours, and then cooled in the furnace.

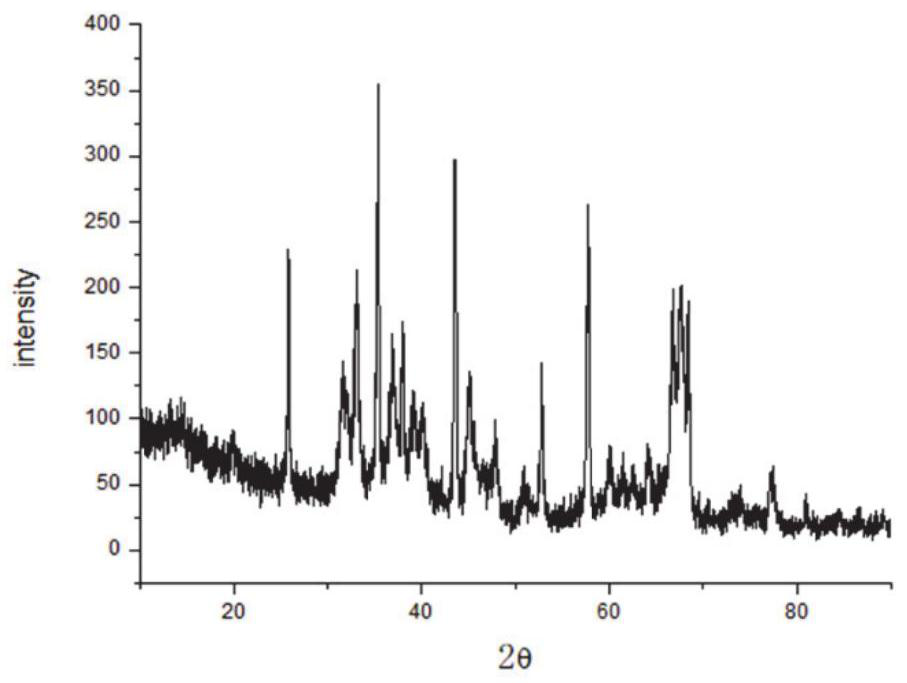

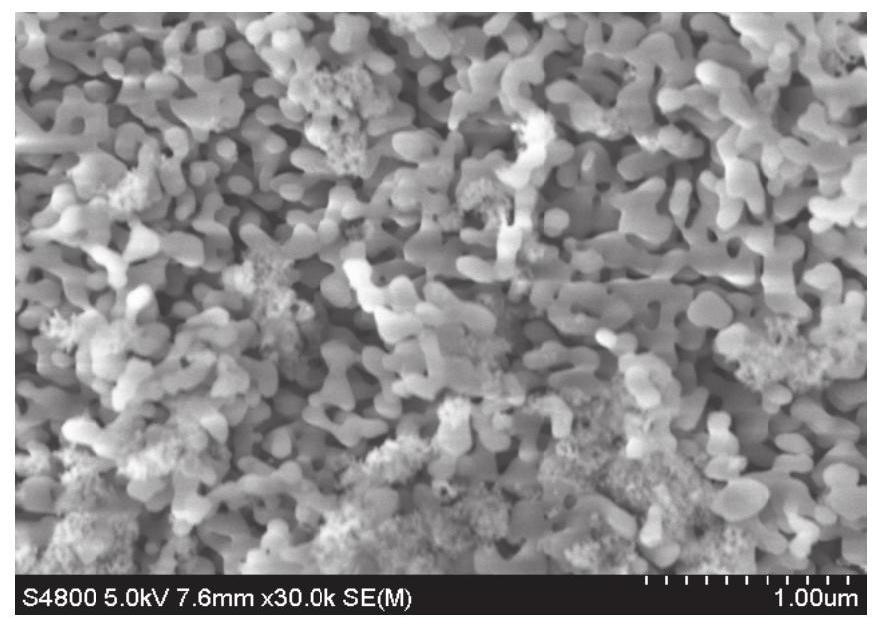

[0063] figure 1 This is the X-ray diffraction pattern of the product obtained in Example 1. It can be seen from the figure that after calcination at 1150°C, the sample obtained by hydrolysis without adding ammonium bicarbonate contains more θ-alumina. From this...

Embodiment 2

[0065] Under magnetic stirring, add 5g of aluminum isopropoxide into 20mL of isopropanol, stir at 70°C for 40min until the aluminum isopropoxide is completely dissolved, then add 15mL of ammonium bicarbonate mixed with 0.005g drop by volume It is a 1:4 mixed solution of water and isopropanol, the hydrolysis temperature is 70°C, and the hydrolysis time is 2h. Stir continuously during the hydrolysis process. After the hydrolysis is completed, continue to stir for 0.5h. The gel obtained after hydrolysis is placed in an oven at 60°C. After drying for 24 hours, the obtained sample was heat-treated in a muffle furnace. The treatment conditions were as follows: the furnace temperature was raised to 1150°C within 2 hours, and kept at 1150°C for 2 hours, and then cooled in the furnace.

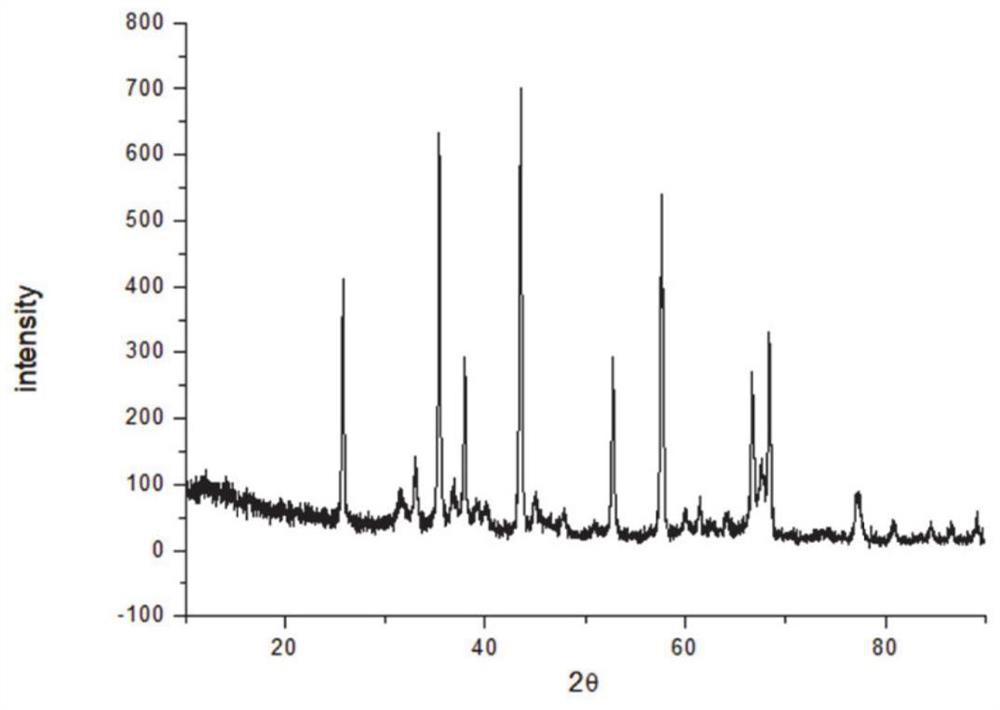

[0066] image 3 This is the X-ray diffraction pattern of the product obtained in Example 2. It can be seen from the figure that after calcination at 1150°C, the sample obtained by adding 0.005g of ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com