Synthesis method of homogeneous polypyrrole nanowire arrays for three-dimensional electrode based on internal filtering flow

A polypyrrole nanowire and three-dimensional electrode technology is applied in the field of synthesis of polypyrrole nanowire arrays, which can solve problems such as unfavorable nanowire material synthesis, uneven growth of polypyrrole nanowire arrays, and the like, and achieve the effect of improving application performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

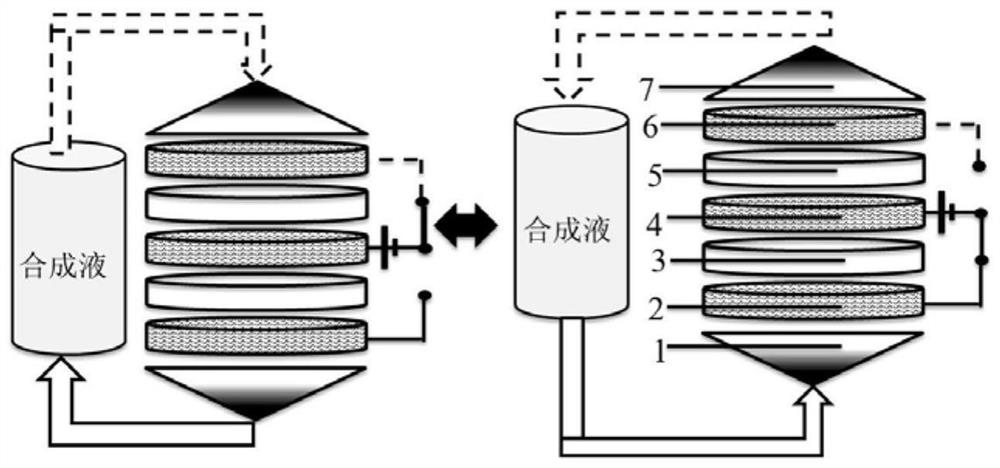

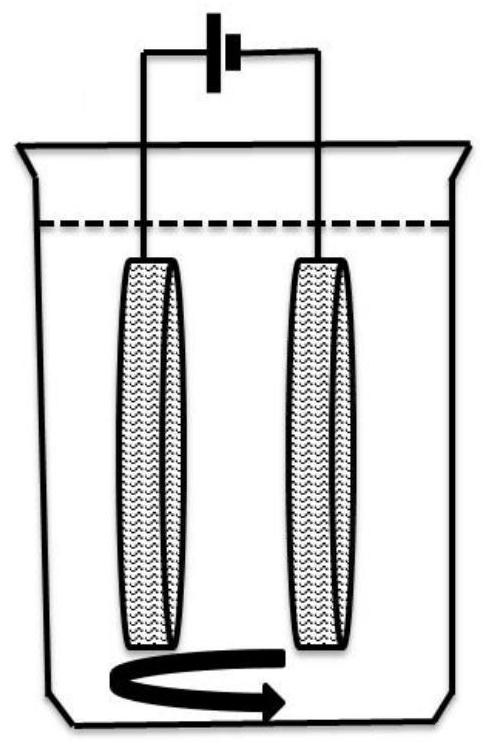

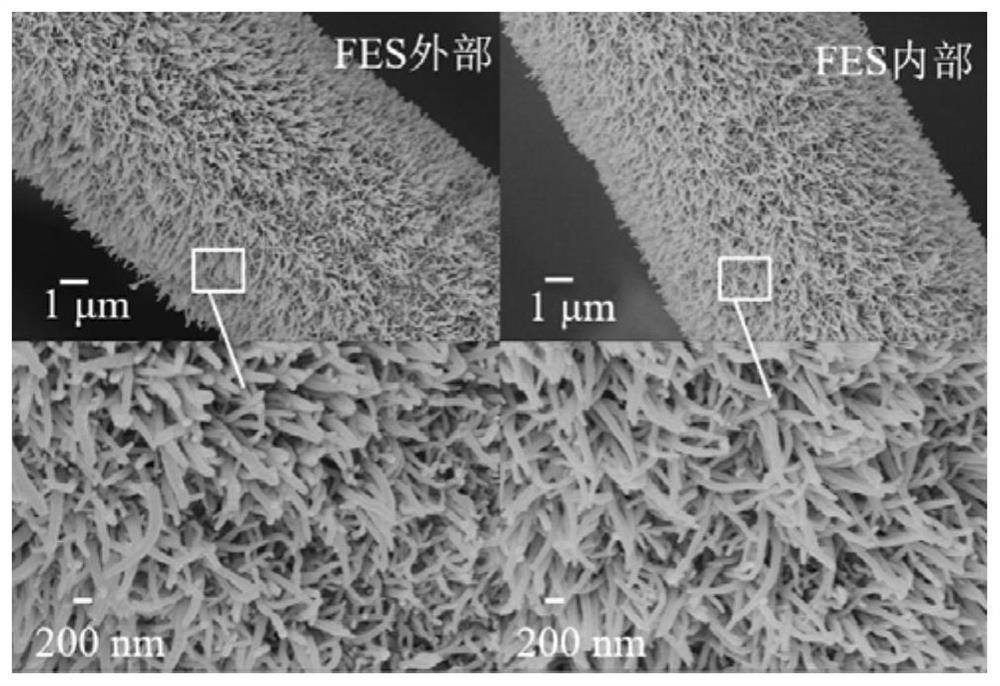

[0038] Steps for synthesizing polypyrrole nanowire arrays (PPyNWs) by internal filtration flow: using carbon fiber mats with a diameter of 5 cm as cathode and anode electrodes to prepare polypyrrole nanowire composite materials, and constructing an internal filtration flow synthesis device. The synthetic solution is prepared by mixing 100ml of phosphate buffer solution with a molar concentration of 0.2mol / L, 100ml of pyrrole with a molar concentration of 0.1mol / L, and 100ml of p-toluenesulfonic acid with a molar concentration of 0.1mol / L. The external voltage was 5V, the running time was 60min, and the flow rate was 10mL / min. During the reaction period, the position of the cathode and the direction of water flow were changed every 5 minutes, for a total of 12 times. After stopping the reaction, the carbon fiber felt at the anode position was washed with pure water to obtain polypyrrole nanowire arrays (PPyNWs). Please refer to figure 1 .

[0039] When the external voltage is...

Embodiment 2

[0043] Example 2: Only Example 1 is changed.

[0044] A graphene sponge with a diameter of 10 cm was used as the cathode and anode electrodes to prepare polypyrrole nanowire composite materials, and an internal filter flow synthesis device was constructed. The volume of the synthesis liquid was 500 mL, and the concentration was the same as in Example 1. The external voltage is 1.5V. The flow rate was 100 mL / min. The running time is 60 minutes, the adjustment time of water flow direction and cathode position is 10 minutes, and the replacement is 6 times in total. After the reaction is stopped, the graphene sponge at the anode position is washed with pure water to obtain a polypyrrole nanowire array (PPyNWs) electrode.

[0045] When the external voltage is 1V, the hydraulic retention time is 15min, and the concentration of E. coli in the influent is 10 4 In the case of CFU / mL, the flow rate is 1000-4000L / m 2 / h, the polypyrrole nanowire arrays (PPyNWs) synthesized by the int...

Embodiment 3

[0046] Example 3: Only Example 1 is changed.

[0047] Polypyrrole nanowire composites were prepared by using carbon fiber felt with a diameter of 5 cm as the cathode and anode electrodes, and three sets of internal filtration flow synthesis devices were constructed. The synthetic liquid volume is 300mL, and concentration is the same as embodiment 1. The external voltage was 2.3V, the running time was 30min, and the flow rates were set to 10, 50, and 100mL / min. During the reaction period, the position of the cathode and the direction of water flow were changed every 5 minutes, a total of 6 times. After the reaction is stopped, the carbon fiber felt at the anode position is washed with pure water to obtain polypyrrole nanowire arrays (PPyNWs). For details, see Figure 5 .

[0048] When the external voltage is 1V, the hydraulic retention time is 15min, and the concentration of E. coli in the influent is 10 4 In the case of CFU / mL, the flow rate is 1000-4000L / m 2 / h, the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com